Fixing device and control method thereof

A fixing device and fixing block technology, used in workpiece clamping devices, semiconductor/solid-state device manufacturing, manufacturing tools, etc., can solve problems such as increasing labor costs, inability to detect whether the clamping has reached a predetermined position, crushing glass substrates, etc. , to achieve the effect of reducing accidents, saving costs and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

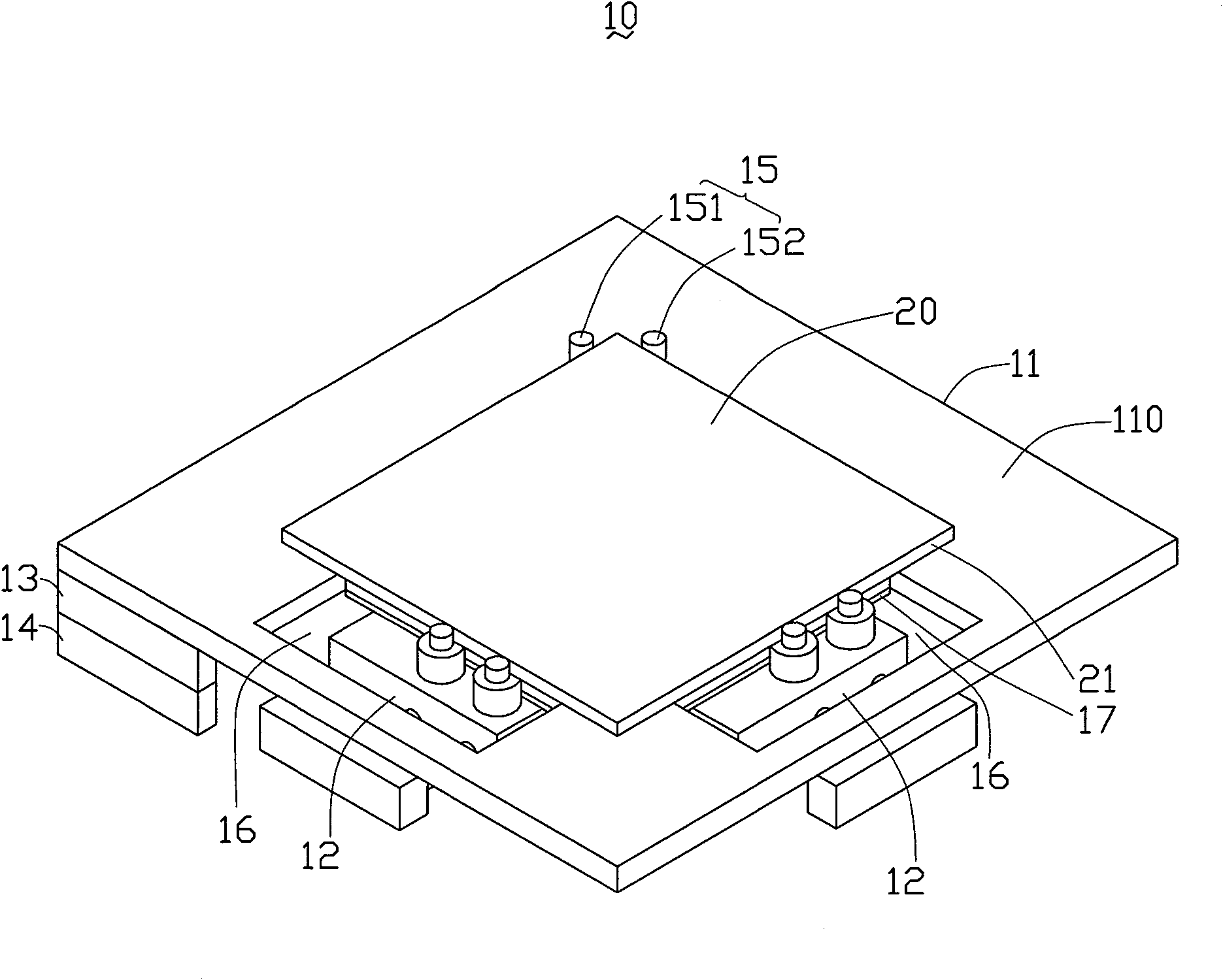

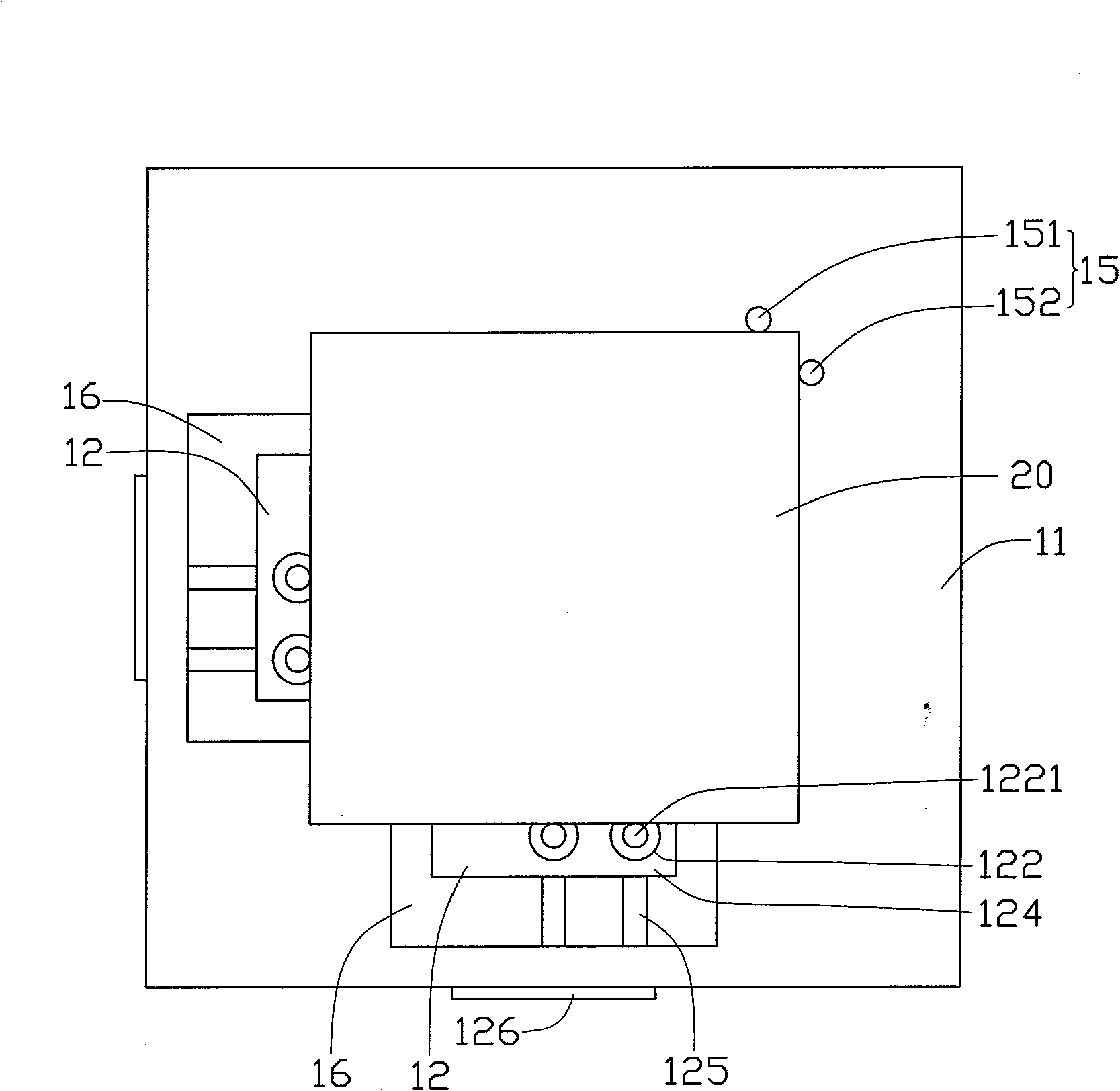

[0015] see Figure 1 to Figure 3 , the fixing device 10 provided by the embodiment of the present invention includes a support plate 11 , a plurality of clamps 12 , a first control unit 13 and a second control unit 14 .

[0016] The support plate 11 is used to support the substrate 20 , and positioning pins 15 , such as a first positioning pin 151 and a second positioning pin 152 , are disposed on the edge of the upper surface 110 .

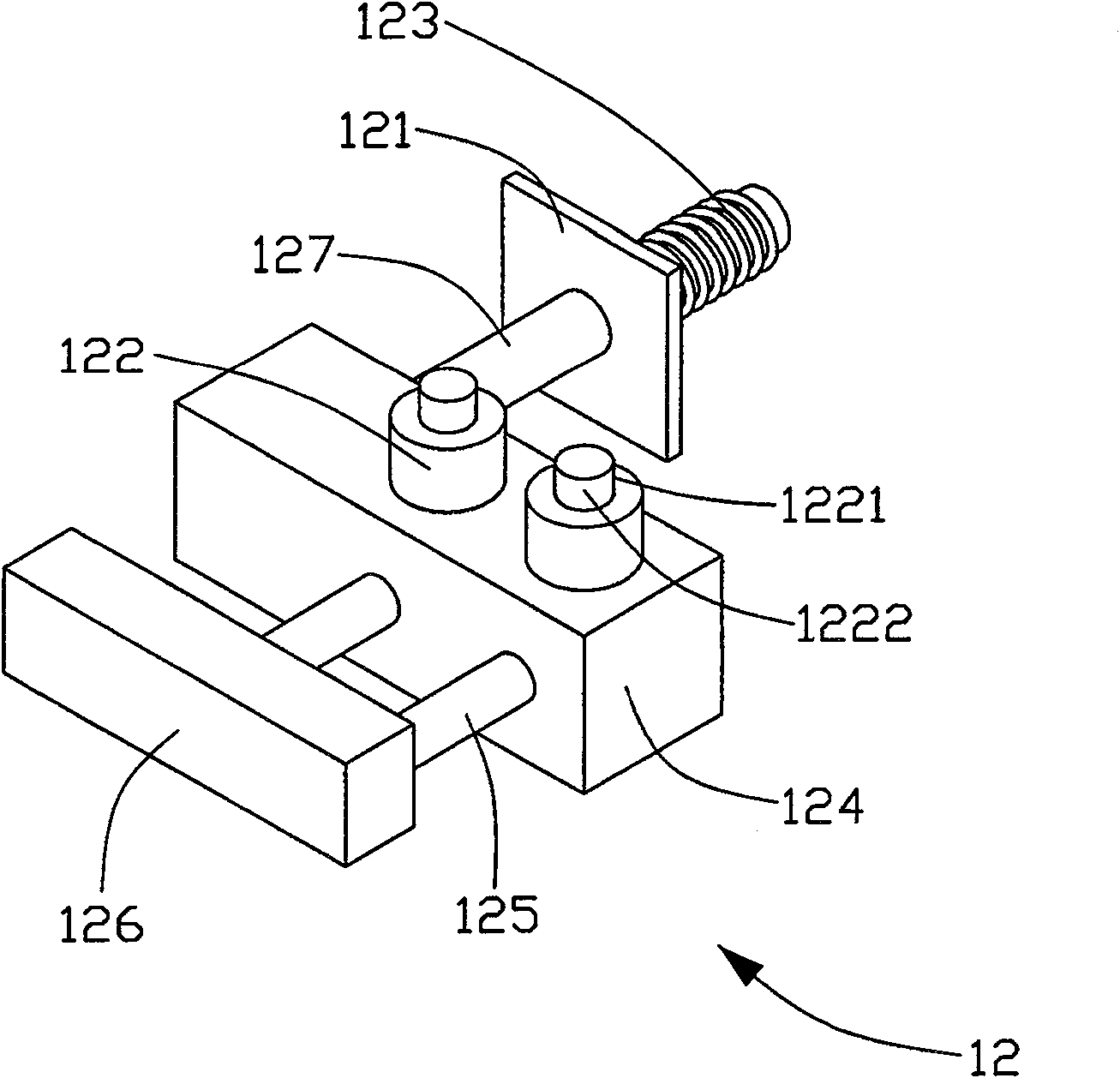

[0017] The plurality of clamps 12 respectively include a permanent magnet 121 , a plurality of resisting pieces 122 , an electric coil 123 and an iron core 127 . The permanent magnet 121 is disposed opposite to the electric coil 123 , the iron core 127 is disposed in the extension direction of the center of the electric coil 123 , and the iron core 127 and the plurality of resisting pieces 122 keep moving syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com