Gas-liquid two-phase thermoacoustic refrigerator

A thermoacoustic refrigeration, vapor-liquid technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems that affect the application, low density, low heat transfer coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

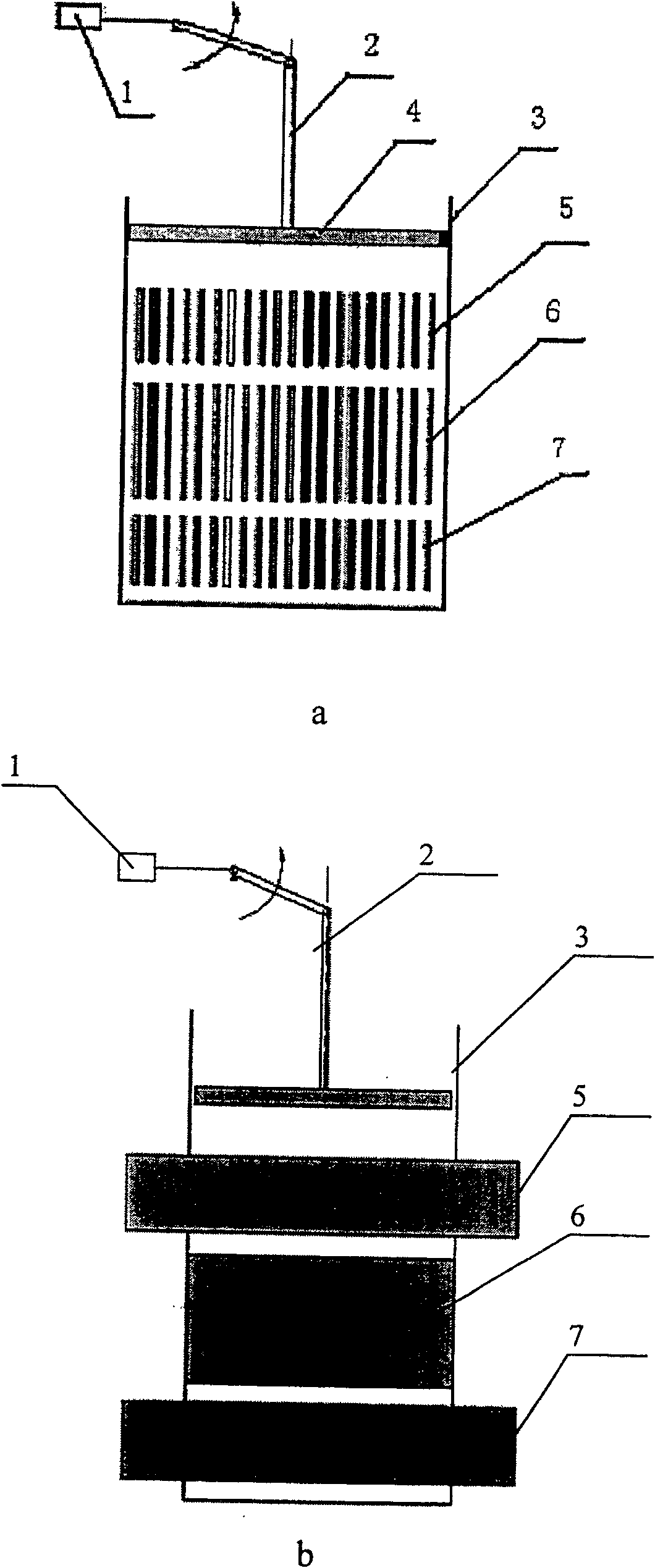

[0011] Example 1, see figure 1 (a), the present invention includes a cavity 3 and a cooler 5, a thermoacoustic sheet 6 and an evaporator 7, which are fixed in the cavity 3 from top to bottom and are composed of parallel plates with equal spacing, and two adjacent parallel plates Fluid working medium channels are formed, and the spacing thereof is 0.05-0.1 times the height of the thermoacoustic sheet 6 . see figure 1 (b) The cooler 5 is composed of metal sheets with good thermal conductivity, the middle part is located inside the cavity 3, and the two ends are in some kind of cooling medium; its function is to discharge the heat generated during the cooling process. The evaporator 7 is composed of a metal sheet with good thermal conductivity, and the two ends protrude out of the cavity to output cooling capacity, and the height of the cooler 5 and the evaporator 7 is 0.4-0.6 of the height of the thermoacoustic sheet 6 made of non-metallic materials times. The functions of th...

Embodiment 2

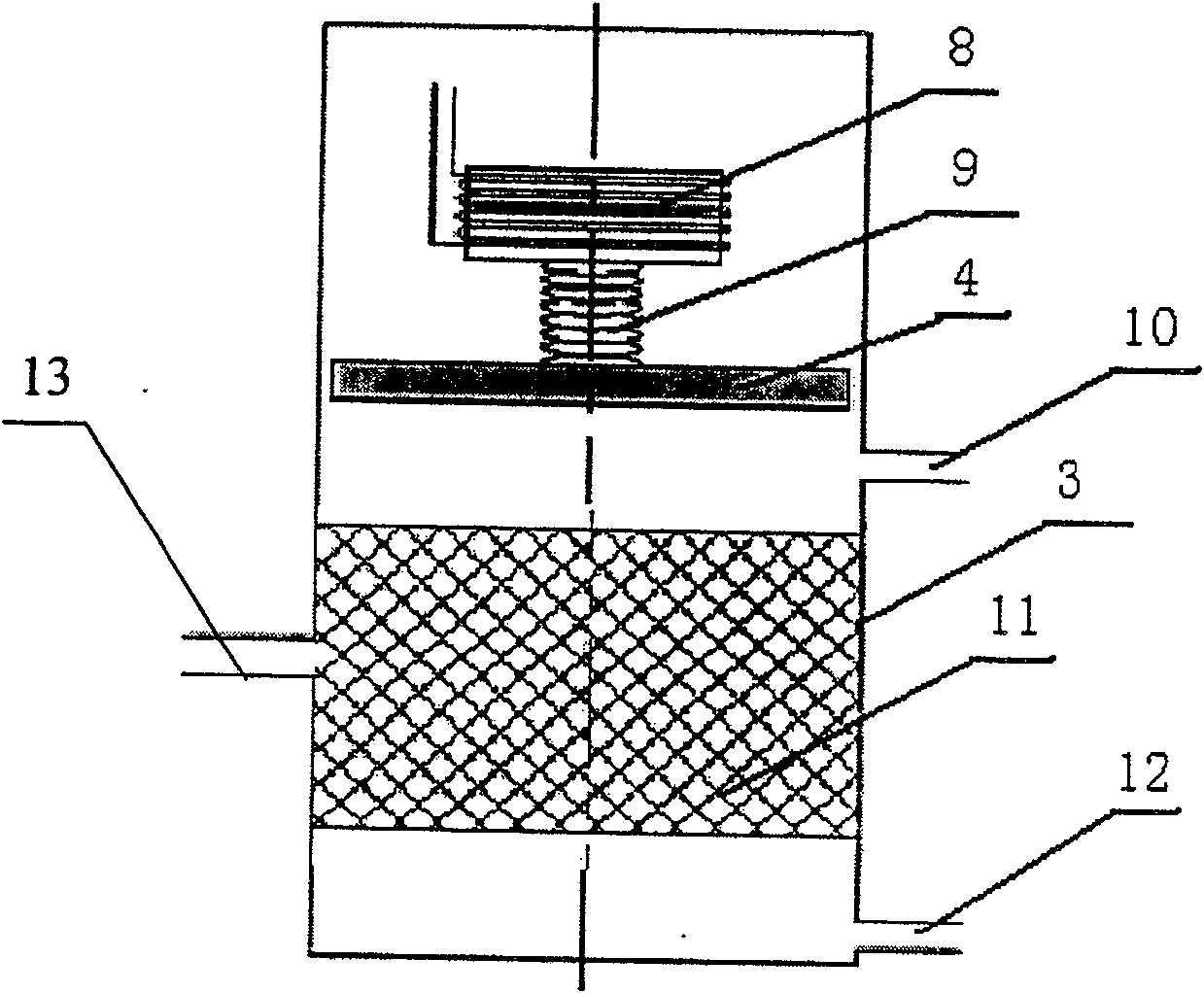

[0012] Example 2: see figure 2 In this embodiment, a three-dimensional grid-shaped heat transfer enhancement element 11 made of wire is arranged in the cavity 3, and a hot water outlet 10, a cold water outlet 12 and a water inlet 13 are opened at the upper and lower ends of the cavity 3 , the piston 4 is connected with the electromagnet 8 through the spring 9, and the electromagnet 8 is connected with the AC power supply. Since the AC power supply alternately transmits power to the electromagnet 8, a magnetic field is alternately generated around the electromagnet 8, and the piston 4 is connected between the magnetic field and the spring 9. Under the action of the cavity 3, it moves up and down, and under the action of the heat transfer strengthening element 11, the water entering the cavity 3 from the water inlet 13 changes, the hot water is discharged from the hot water outlet 10, and the cold water is discharged from the cold water outlet 12 discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com