Sleeve of power supply socket

A technology for power sockets and sockets, applied in the direction of contact parts, etc., can solve the problems of increasing the contact area and the clamping force of the socket, poor contact, complicated process, etc., to increase the support contact area, solve the problem of small contact area, The effect of simple production process

Inactive Publication Date: 2010-02-10

周晓华

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The national standard stipulates that the pins on the power plugs for household and similar purposes are flat, and the pins on the power plugs for household and similar purposes in many countries in the world are mostly flat. But it is unreasonable. The shape and structure of the socket is mostly a simple "U"-shaped groove that tightens the neck. When the plug is inserted into the power socket, it often occurs: First, the contact between the socket and the pin is a line contact, and the contact area is very small, resulting in The flow capacity is small; the second is that the clamping pin of the socket is only clamped by the mechanical elasticity of the socket, the clamping force is small, and the contact is not firm; the third is that the plug is inserted in the power socket for a long time, and the mechanical elasticity of the socket in the power socket Gradually decrease until lost, prone to poor contact

Due to the small contact area, small clamping force and easy loss of clamping force after long-term use, the contact resistance is large, and the contact part is prone to heat. The heat in turn promotes the accelerated decrease and loss of the mechanical elasticity of the socket, and further increases the contact resistance. large, forming a vicious circle, the probability of danger and the large

In addition, some power socket inserts use methods such as nickel plating, silver or alloy to reduce contact resistance; some increase the thickness of the copper sheet of the power socket insert to increase the clamping force, but none of them effectively increase The large contact area and the clamping force of the socket, on the contrary increase the production costs

Some power outlet sockets use a simple positive and negative tolerance between the sleeve and the pin to increase the clamping force. When the socket is just used, the clamping force is relatively large. The fit is lost, and the socket finally loses its clamping force; some power sockets increase the clamping force of the socket by adding external springs or shrapnel, but the process is complicated and the cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

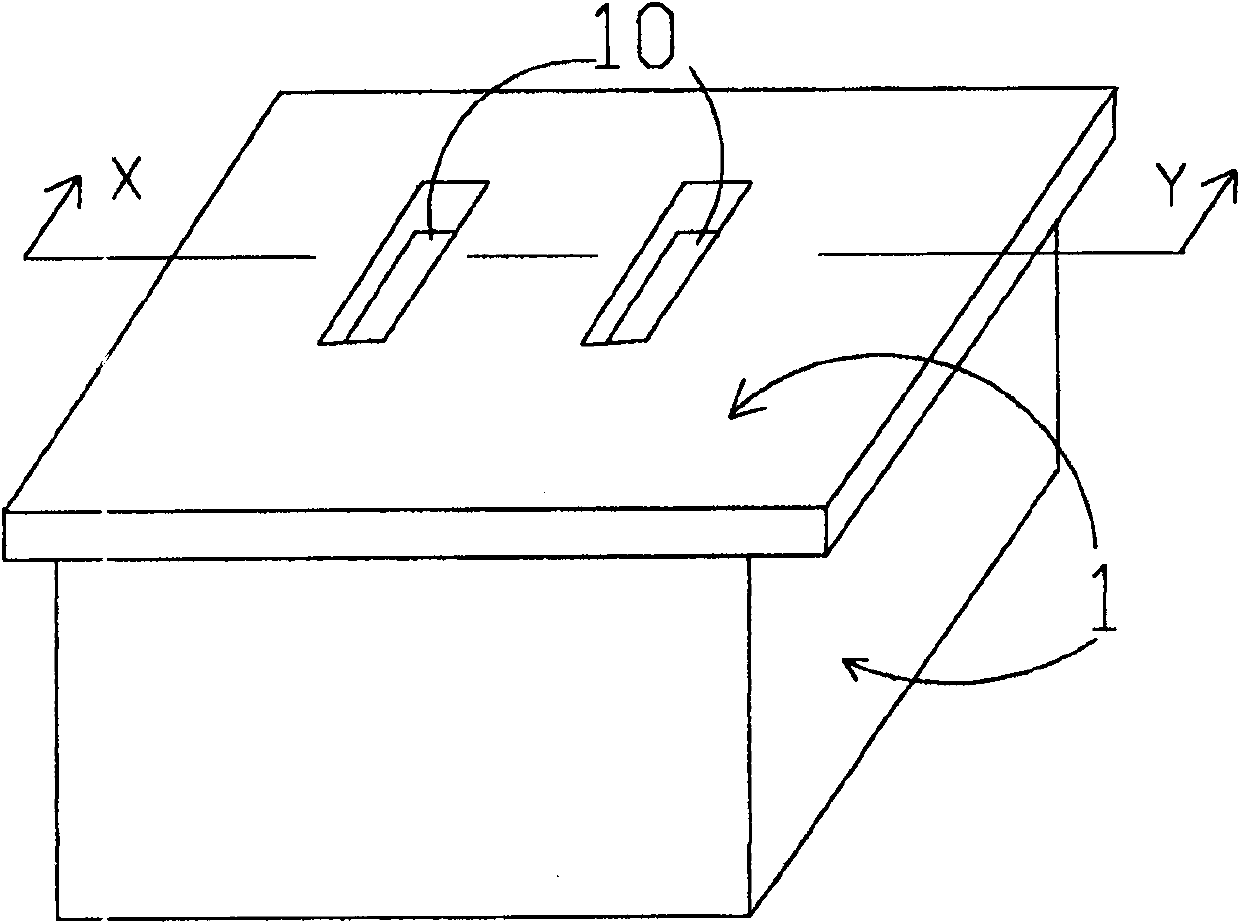

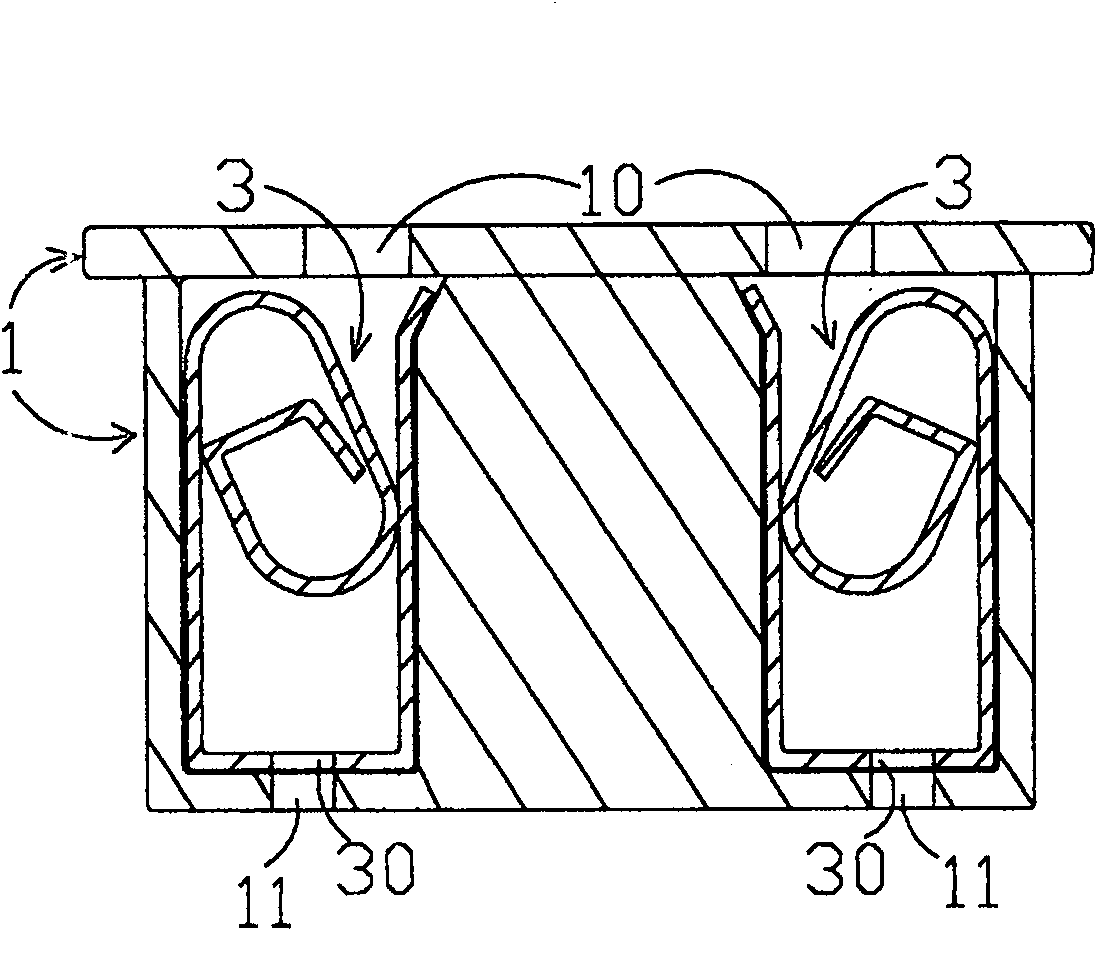

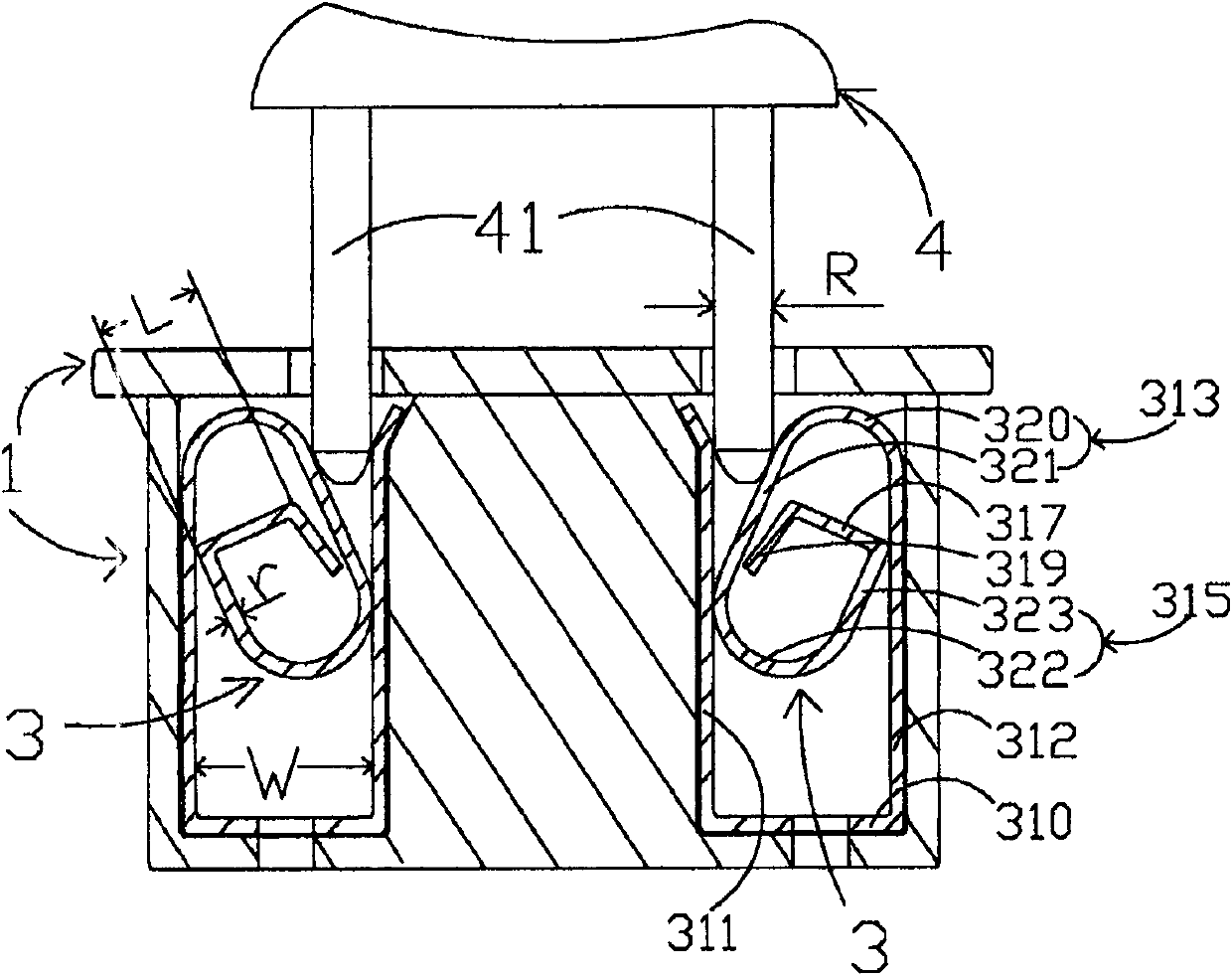

The invention provides a household or the same power socket sleeve with reliable contact, large contact area and large flow capacity with the power plug. An oblique elastic contact sheet, an oblique elastic bearing sheet, a rotatable supporting arm and an elastic auxiliary stay sheet are bent in turn from the upper end of the shot wall to the sleeve inner. When the sleeve and the bolt are completely tabled, the rotatable supporting arm removes along the tabling direction to the level position, rotates in the sleeve to become a supporting beam, supported between the slot walls to become a 'permanent supporting arm', which pushes the bolt to contact with the tight surface of the sleeve, namely becoming the maximized permanent clamping force, which does not weaken or lose never.

Description

Technical field The present invention relates to a power socket for household use and the like. The socket of the power socket has the maximum permanent clamping force. Background technique The national standard stipulates that the pins on the power plugs for household and similar purposes are flat, and the pins on the power plugs for household and similar purposes in many countries in the world are mostly flat. But it is unreasonable. The shape and structure of the socket is mostly a simple "U"-shaped groove that tightens the neck. When the plug is inserted into the power socket, it often occurs: First, the contact between the socket and the pin is a line contact, and the contact area is very small, resulting in The flow capacity is small; the second is that the clamping pin of the socket is only clamped by the mechanical elasticity of the socket, the clamping force is small, and the contact is not firm; the third is that the plug is inserted in the power socket for a long ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01R13/11

Inventor 周晓华

Owner 周晓华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com