Incontinence trousers reciprocating welding system and welding method thereof

A technology of welding system and incontinence pants, applied in the direction of sewing tools and other directions, can solve the problems of insufficient strength, environmental protection, and high system cost, and achieve the effect of high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

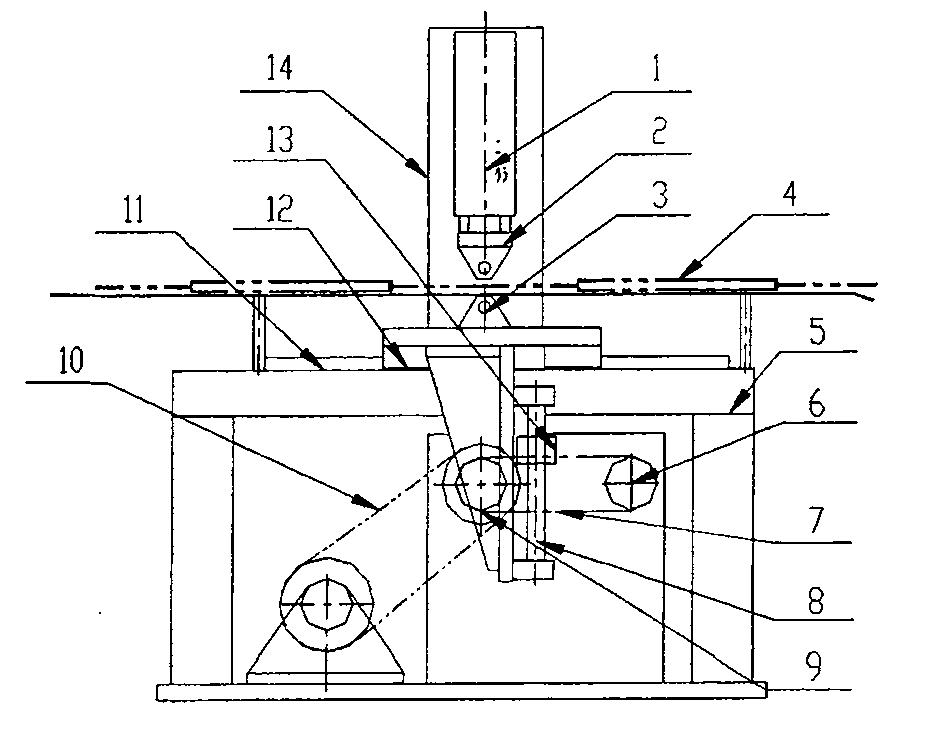

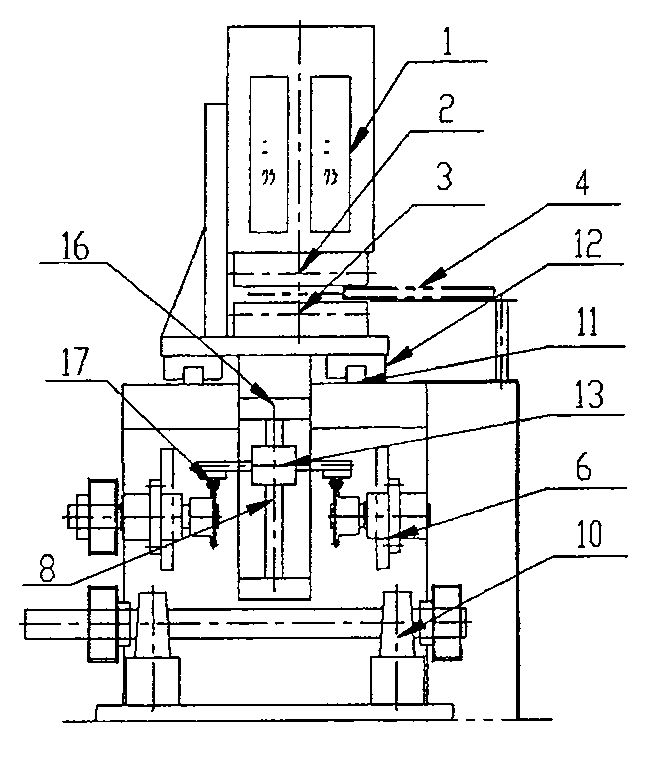

[0011] Embodiment 1: with reference to attached Figure 1~3 . The reciprocating welding system for incontinence trousers includes two guide rails 11 of a driving source (motor) manufactured by prior art and respectively located on the workbench of frame 5, which is manufactured by prior art. The movable welding knife rest 14 is made of a knife rest (preferably an L-shaped knife rest), a cylinder 1, a mover 2, and a stator 3, and an electric heating source is built in the stator 3 or the mover 2 or the stator 3 and the mover 2. The cylinder 1 is located on the tool rest, the mover 2 is connected to the piston head of the cylinder 1, and the stator 3 is located on the tool rest and below the mover 2 . Sliders 12 are installed at the bottom of the movable welding tool rest 14 and are slidingly matched with the guide rails 11 respectively. The sliders 12 are 4 to 6 pieces or more and have a groove structure. The sliders are located (installed) on the movable welding tool rest 14...

Embodiment 2

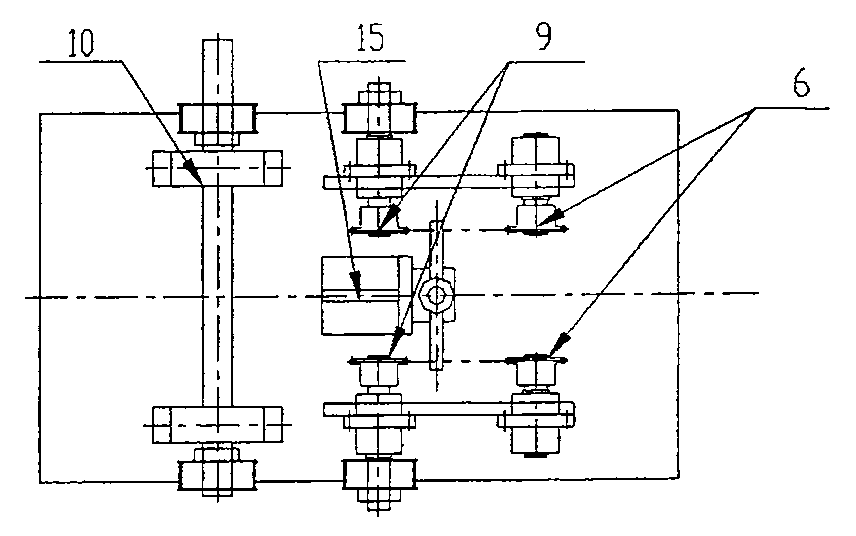

[0012] Embodiment 2: On the basis of Embodiment 1, the welding method of the reciprocating welding system for incontinence pants, the two chains 7 connected to the two connectors 17 fixed on both sides of the knife rest driving device 15 are respectively set on the driving sprocket 9 and the driven sprocket 6 form a closed sprocket chain transmission mechanism. The driving source---the motor drives the synchronous belt transmission mechanism 10 to rotate, and the synchronous belt transmission mechanism 10 drives the closed sprocket chain transmission mechanism to work. When the chain 7 drives the movement The movable welding knife rest 14 moves forward synchronously, and the welding place of the incontinence pants 4 to be welded enters the welding surface formed by the mover 2 and the stator 3 in the movable welding knife rest 14. When welding, the piston in the cylinder 1 drives the mover 2 Press down and press the welded part of the incontinence pants 4 against the hot melt w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com