Patents

Literature

51results about How to "Long welding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

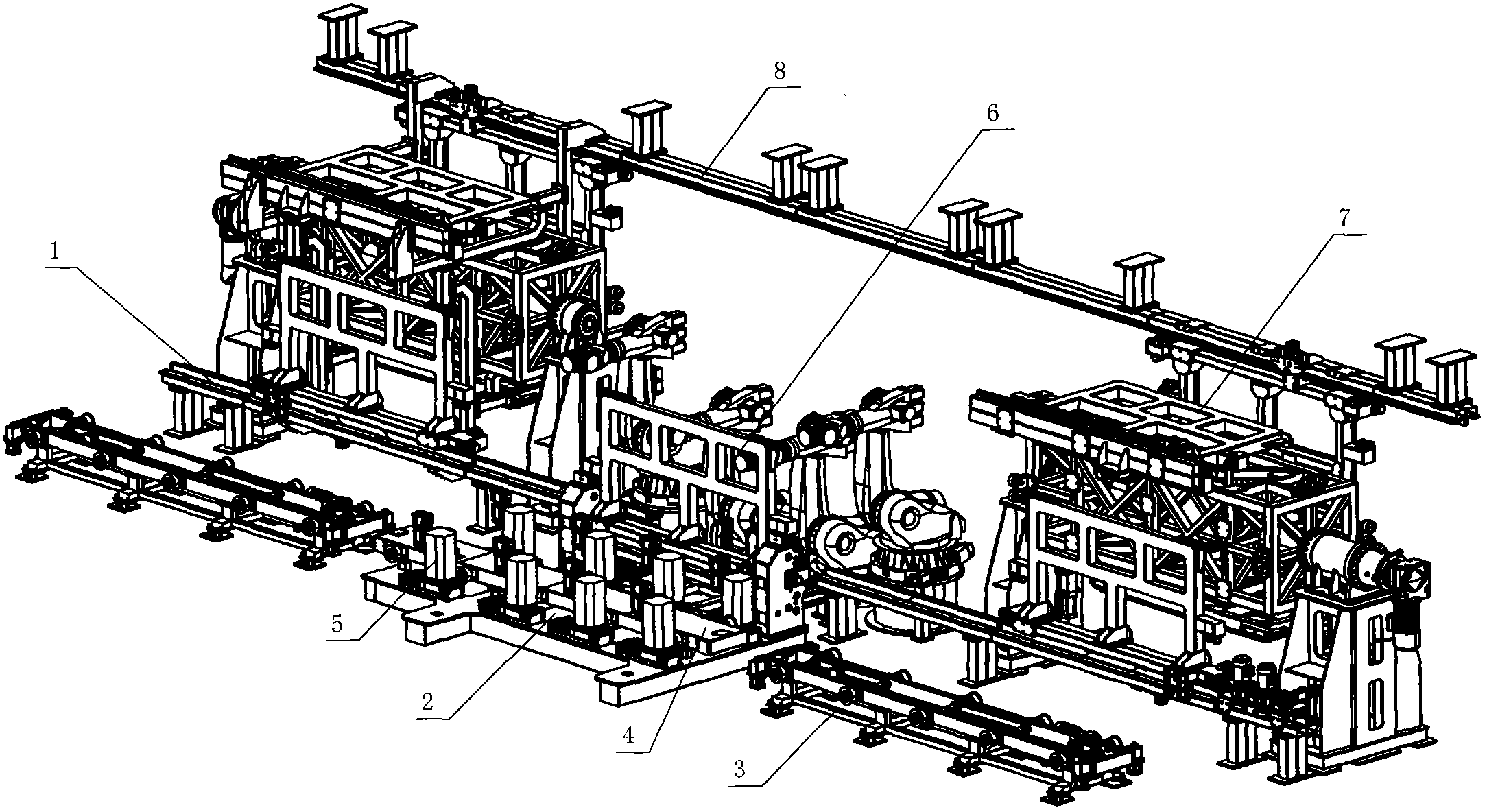

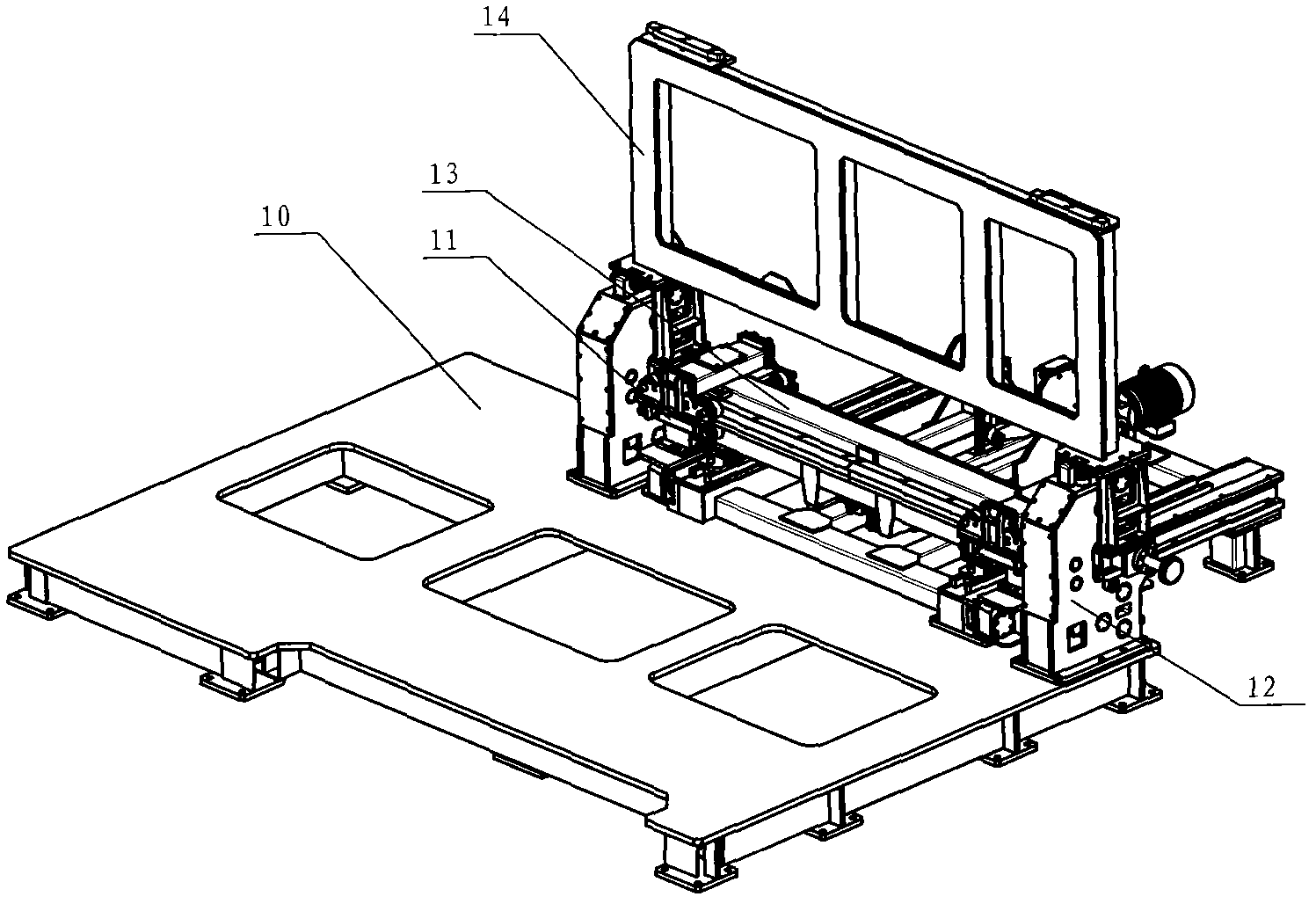

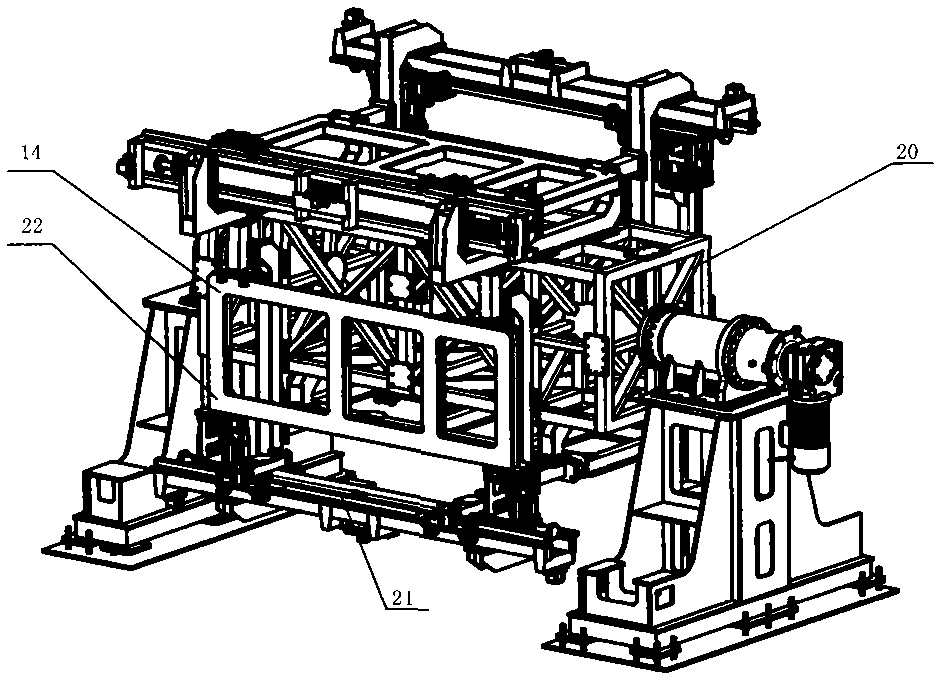

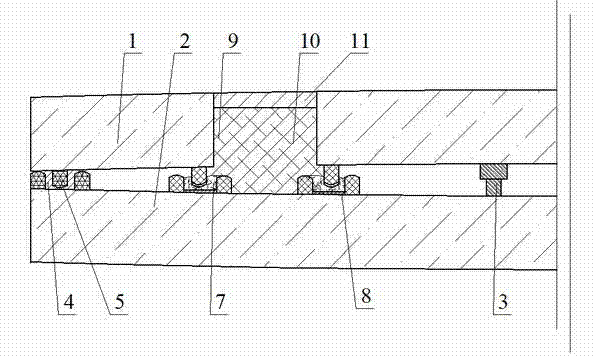

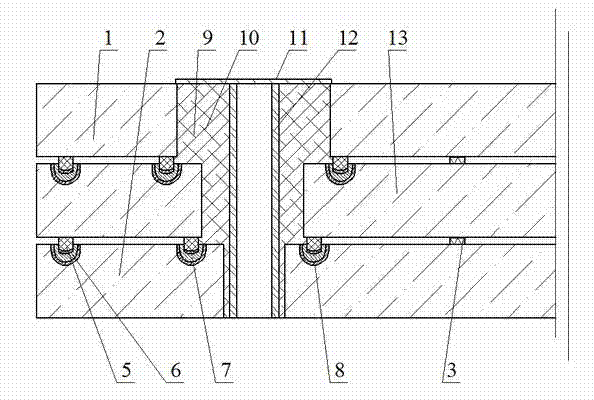

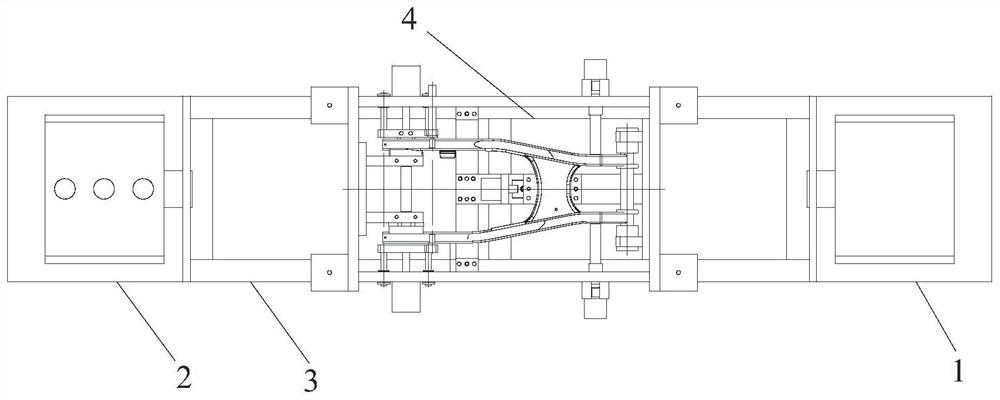

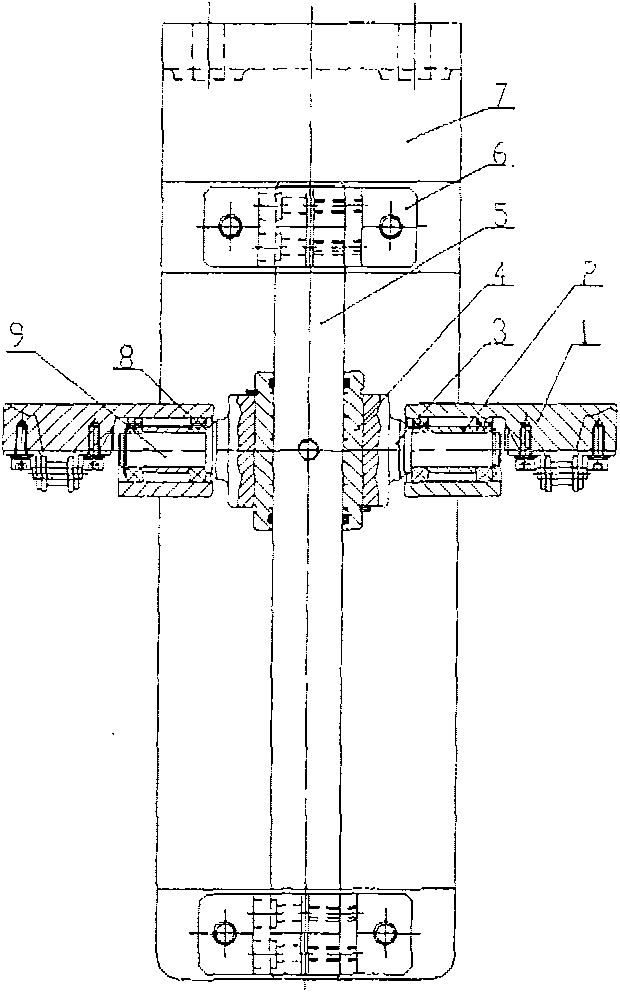

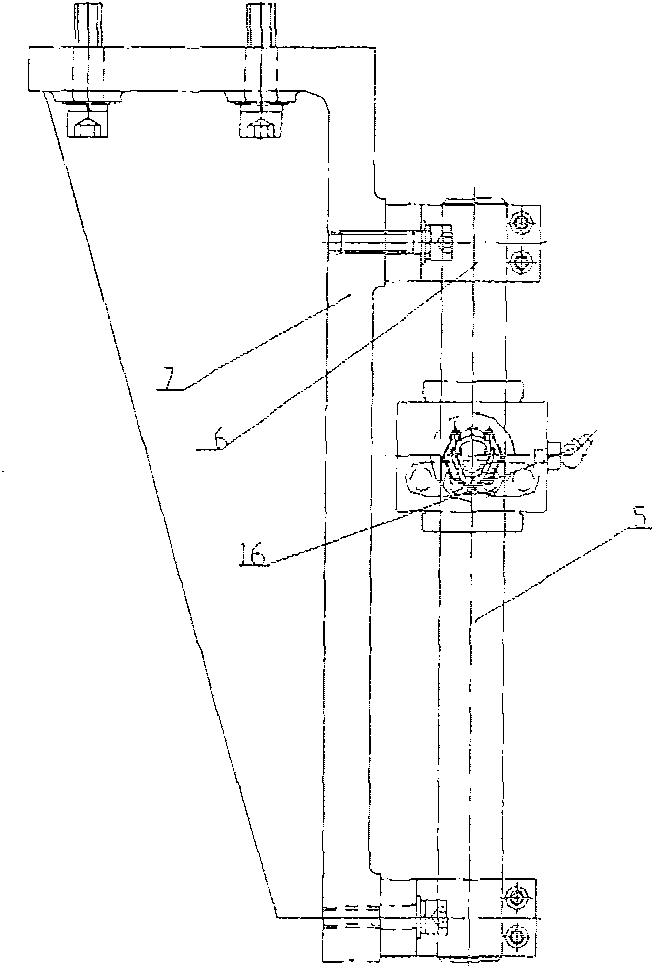

Collinear flexible head splicer suitable for multiple vehicle types

ActiveCN102837138ASmall footprintIncrease the number ofWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

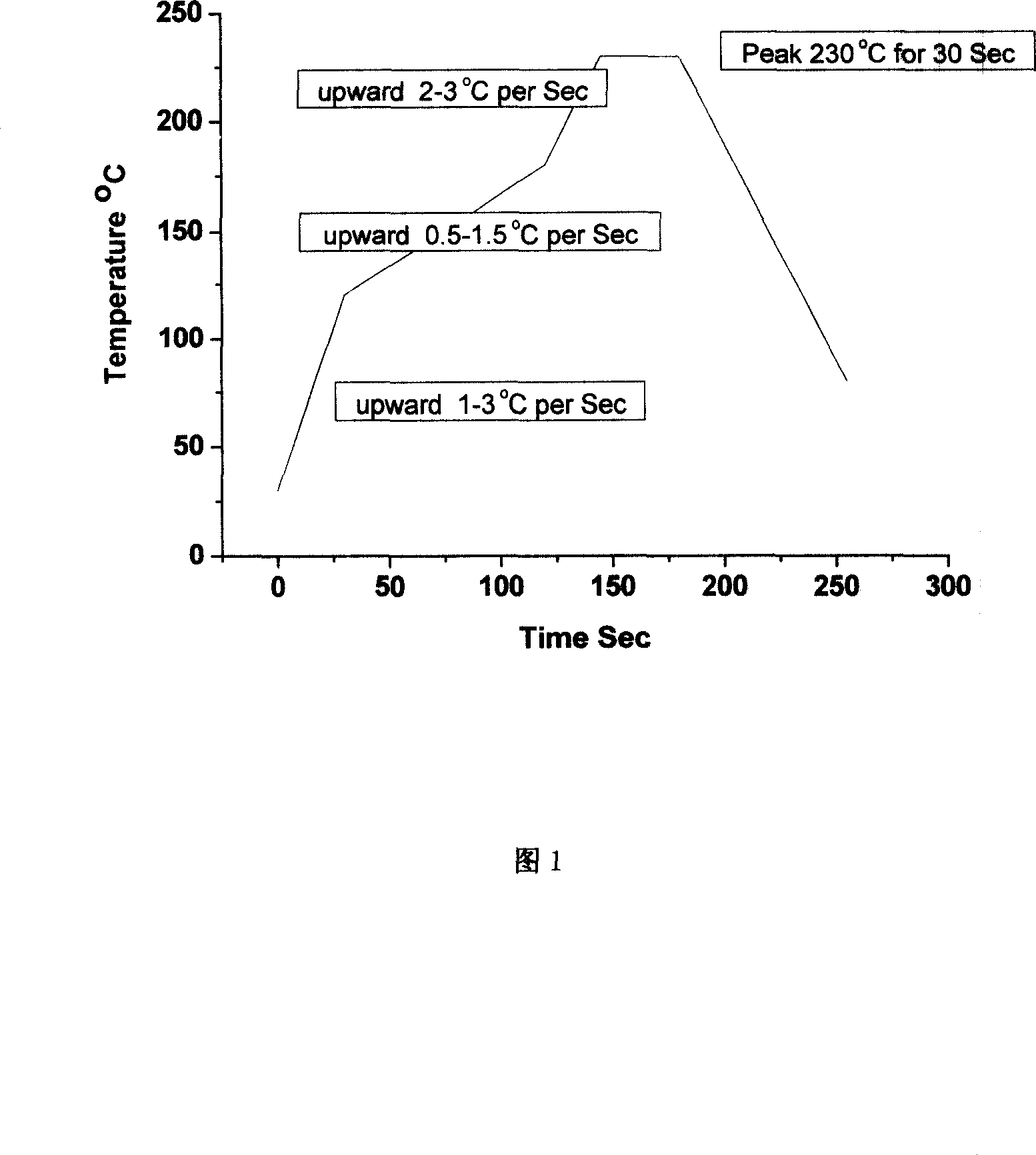

Leadless alloy tin solder plaster and manufacturing method thereof

InactiveCN101011784AImprove wettabilityGood welding performanceWelding/cutting media/materialsSoldering mediaOrganic solventMonoglyceride

The invention discloses a tin solder plaster of leadless alloy and making method, which consists of soldering flux and leadless tin solder alloy powder, wherein the soldering flux is composed of organic solute and organic solvent; the organic solute contains macromolecular PVP, macromolecular PEG and or PVA, abietic acid or modified abietyl, aliphatic acid monoglyceride and aliphatic acid sorbate; the organic solvent is one or more composition of anhydrous alcohol, ethandiol, cycloethane, glycol ethylene and diglycol ethylene.

Owner:苏州盖依亚生物医药有限公司

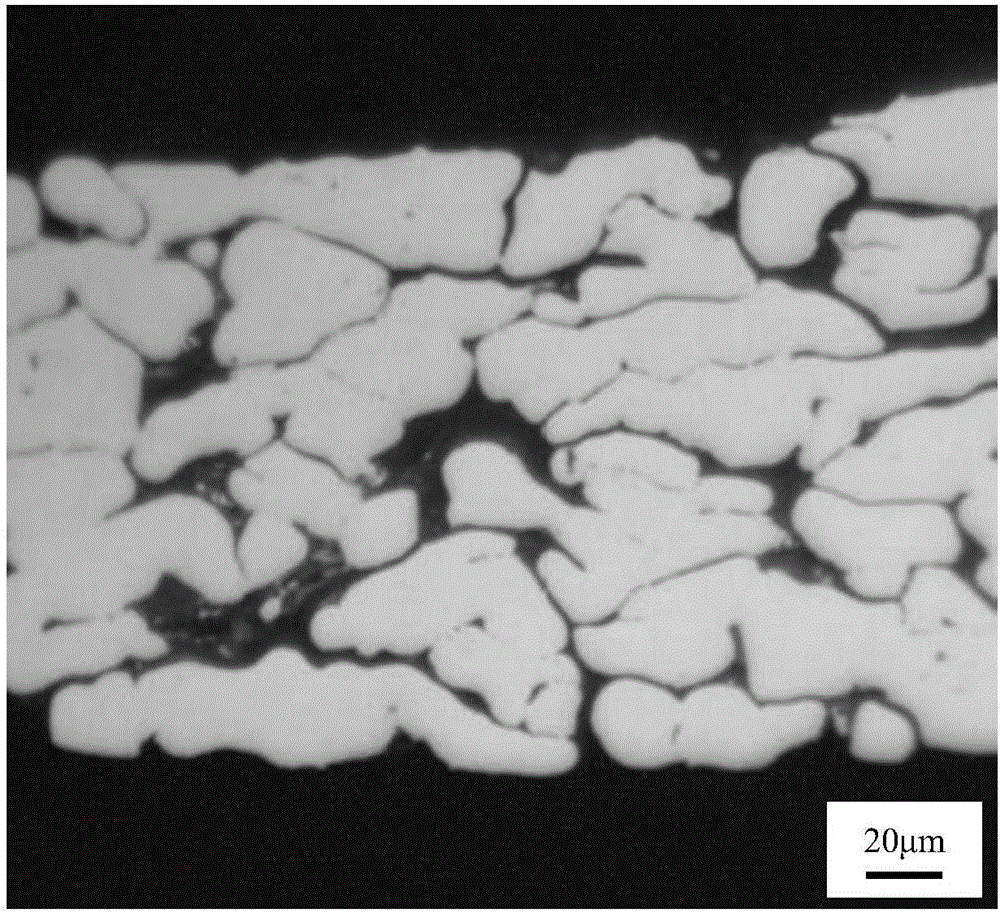

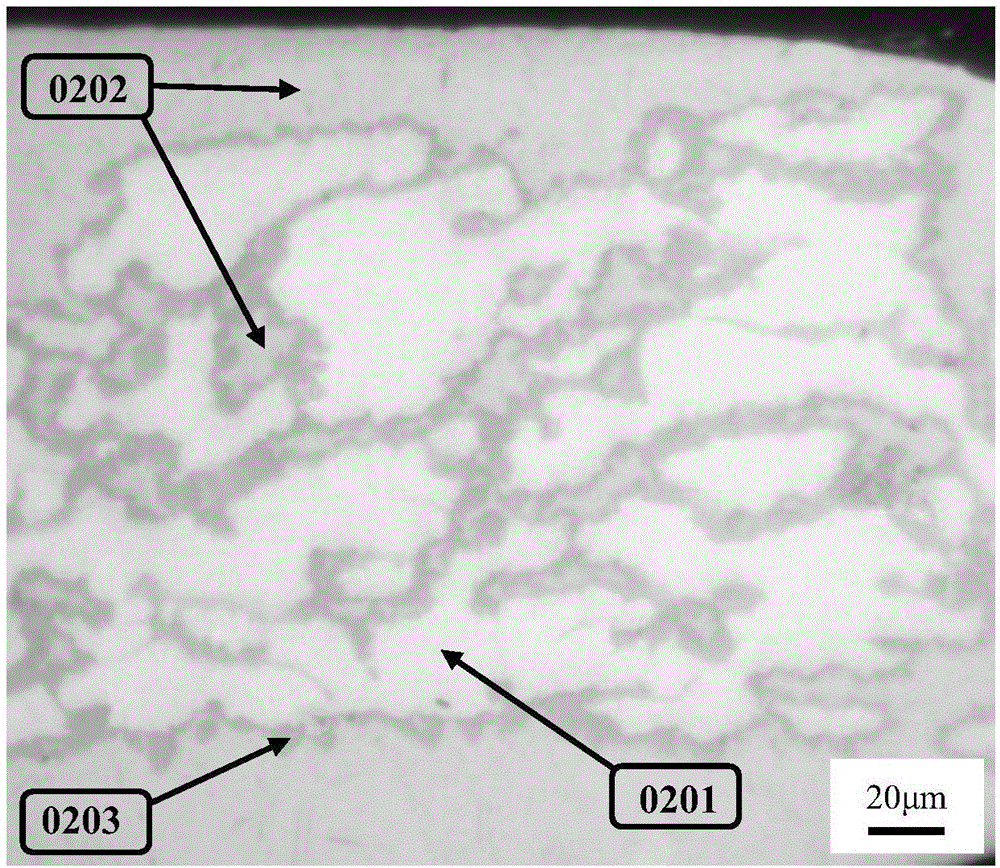

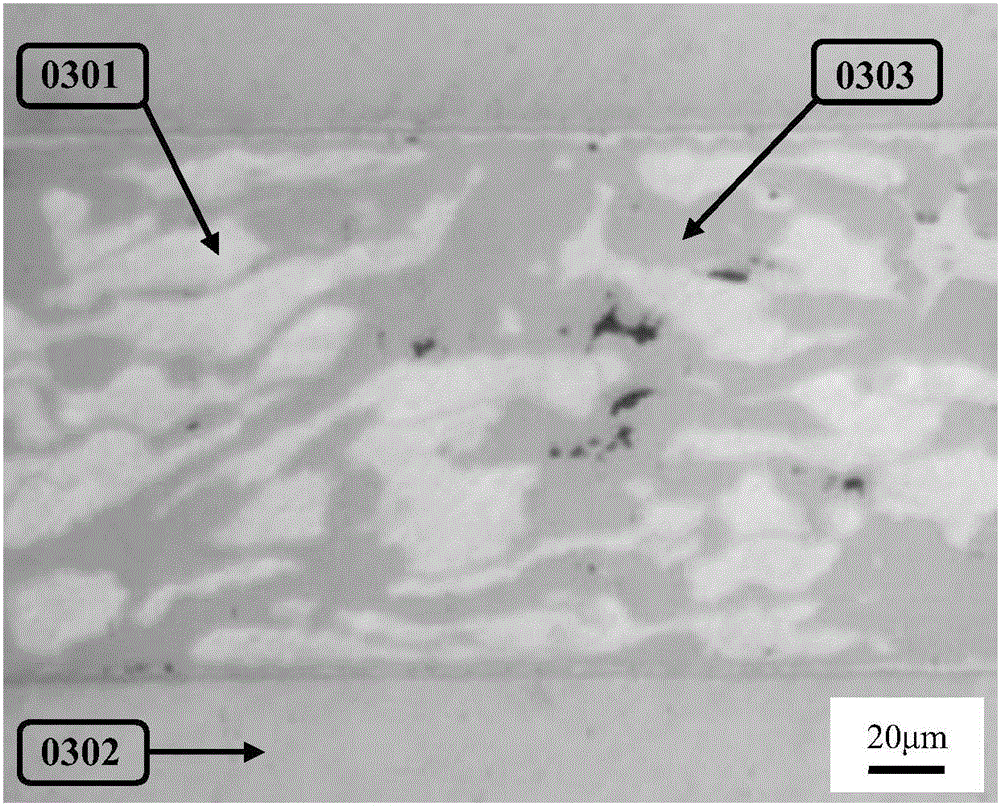

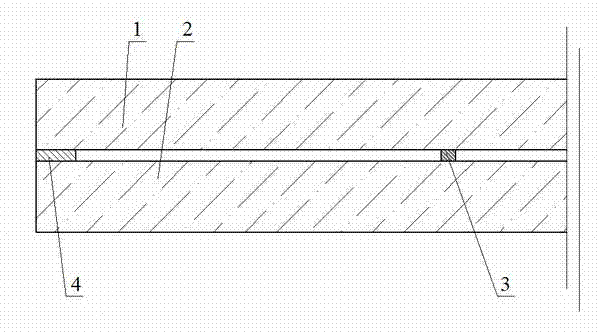

High-temperature brazing filler metal preparing method based on foamed silver filled with metal tin

InactiveCN106216873AImprove mechanical propertiesImprove plasticityWelding/cutting media/materialsSoldering mediaMetal sheetLiquid metal

The invention provides a high-temperature brazing filler metal preparing method based on foamed silver filled with metal tin. High-temperature brazing filler metal is a metal sheet formed by the foamed silver with micro and nanoscale pores filled with the metal tin, the foamed silver is filled with liquid metal tin through the capillary action, and preparing of the brazing filler metal is achieved. When the brazing filler metal is used for welding, a finally-formed welding line is composed of an intermetallic compound and remaining foamed silver, low-temperature welding can be achieved, an obtained welding point can be subject to high-temperature service, welding point reliability and welding line stability are greatly improved, and the method can be widely applied to various high-temperature welding fields.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

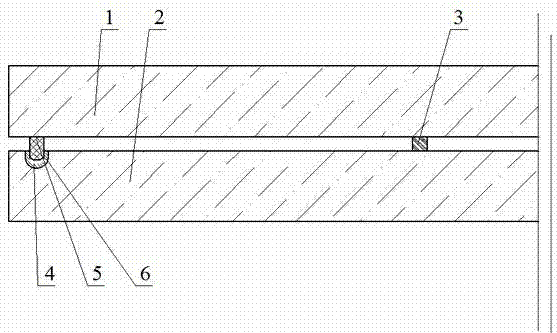

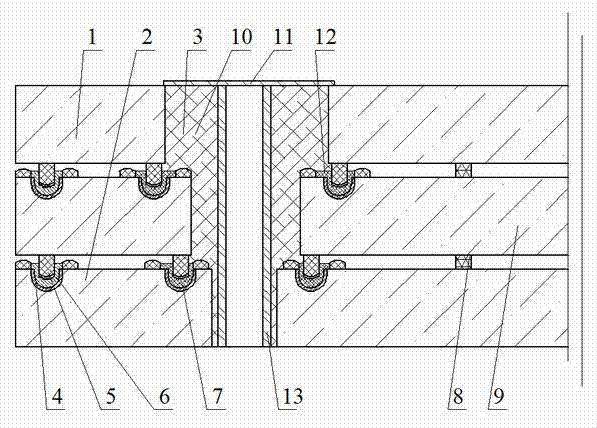

Vacuum glass laminated at high temperature and production method thereof

InactiveCN104743842AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a vacuum glass laminated at high temperature, which comprises an upper glass and a lower glass, the upper glass and the lower glass are plane glass or convex glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder or a metal solder in a vacuum furnace, an enclosing vacuum layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the vacuum layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

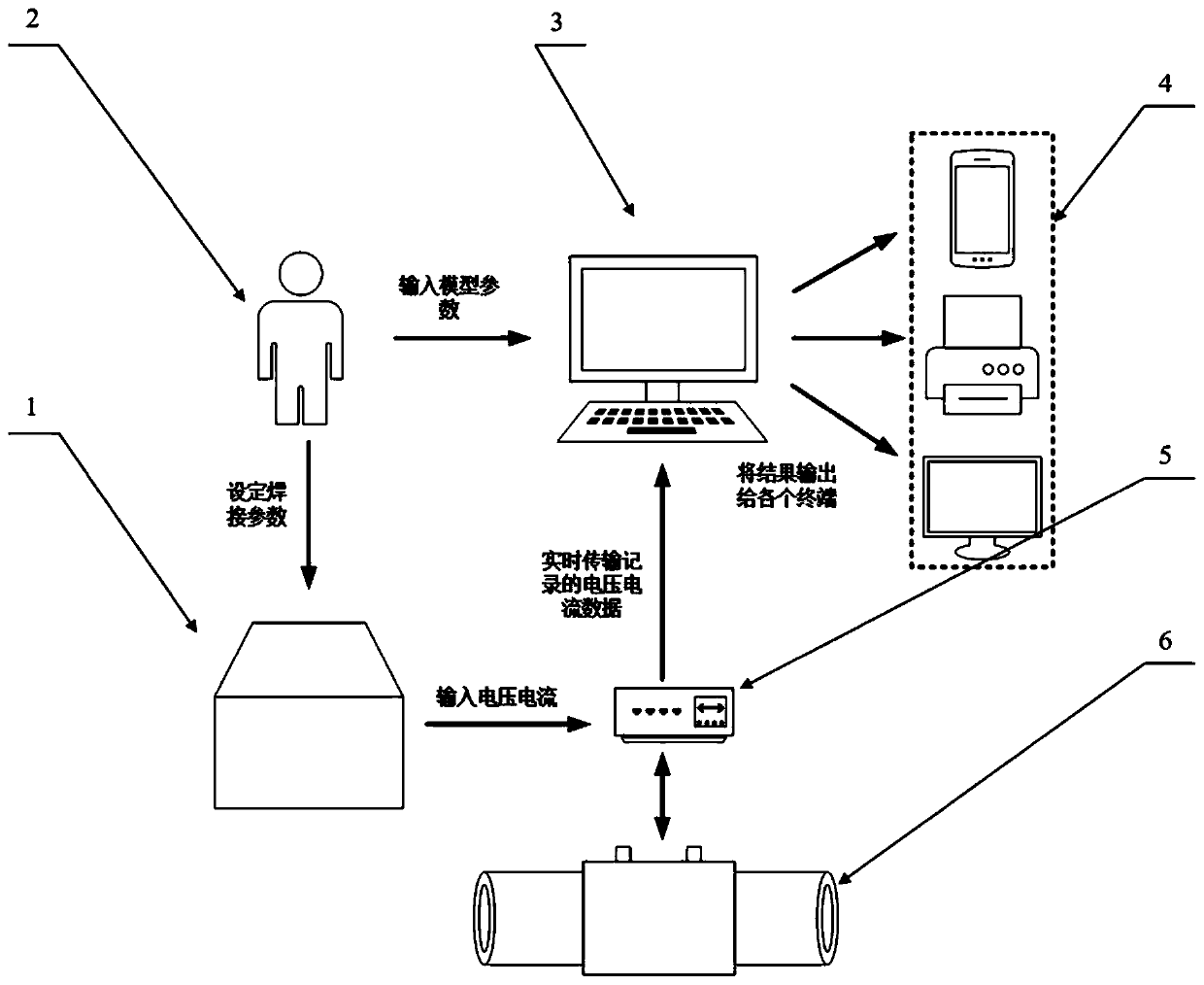

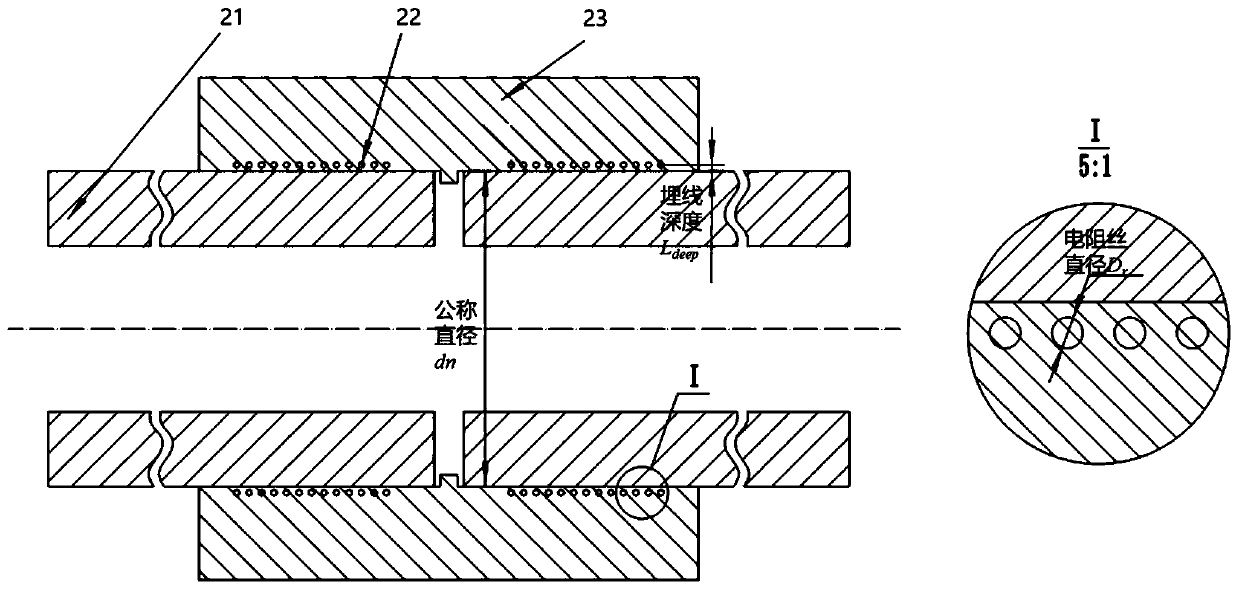

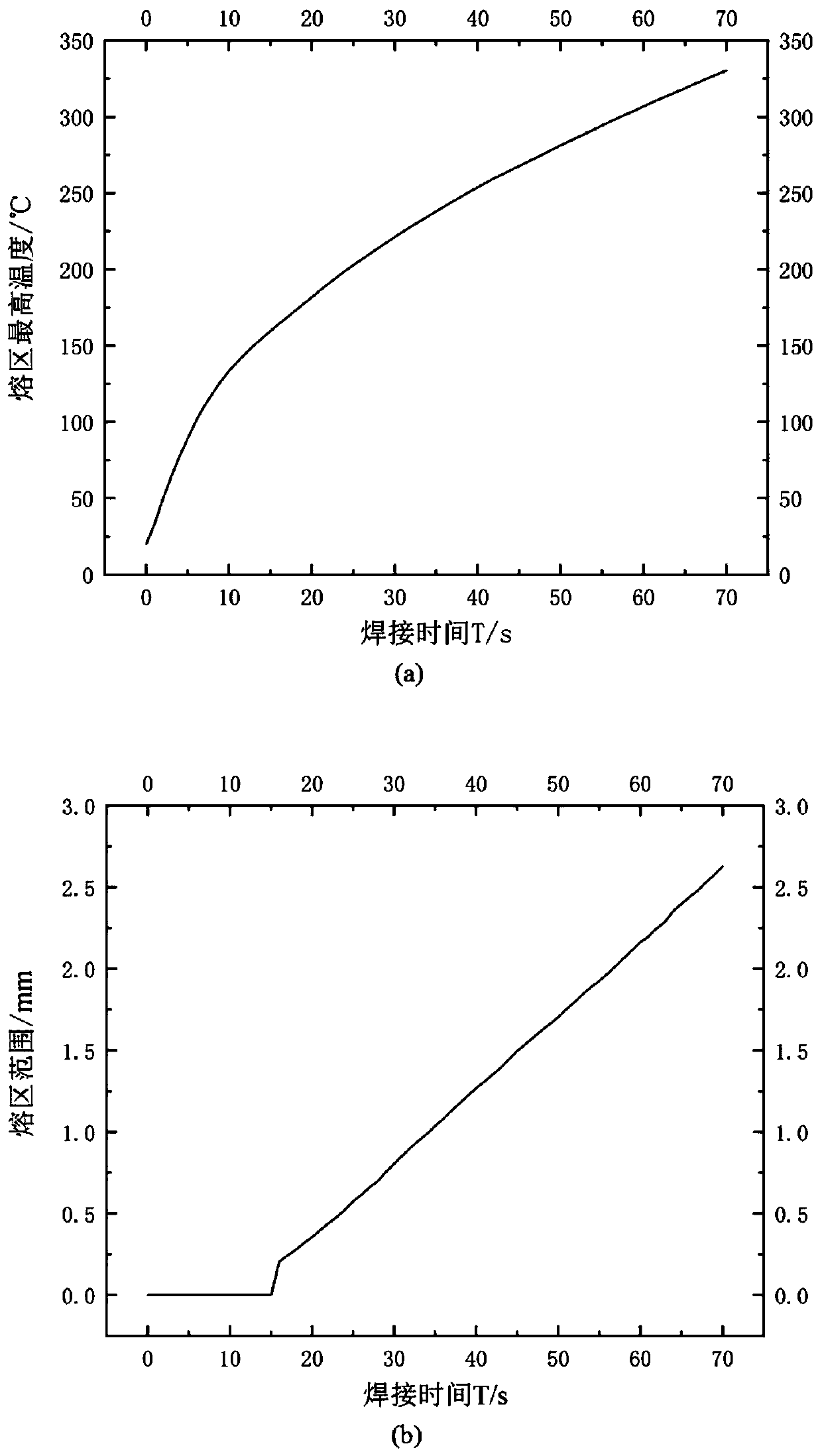

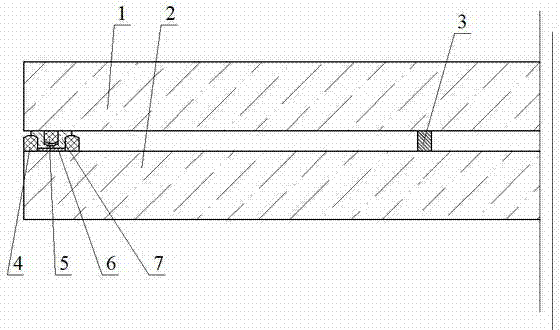

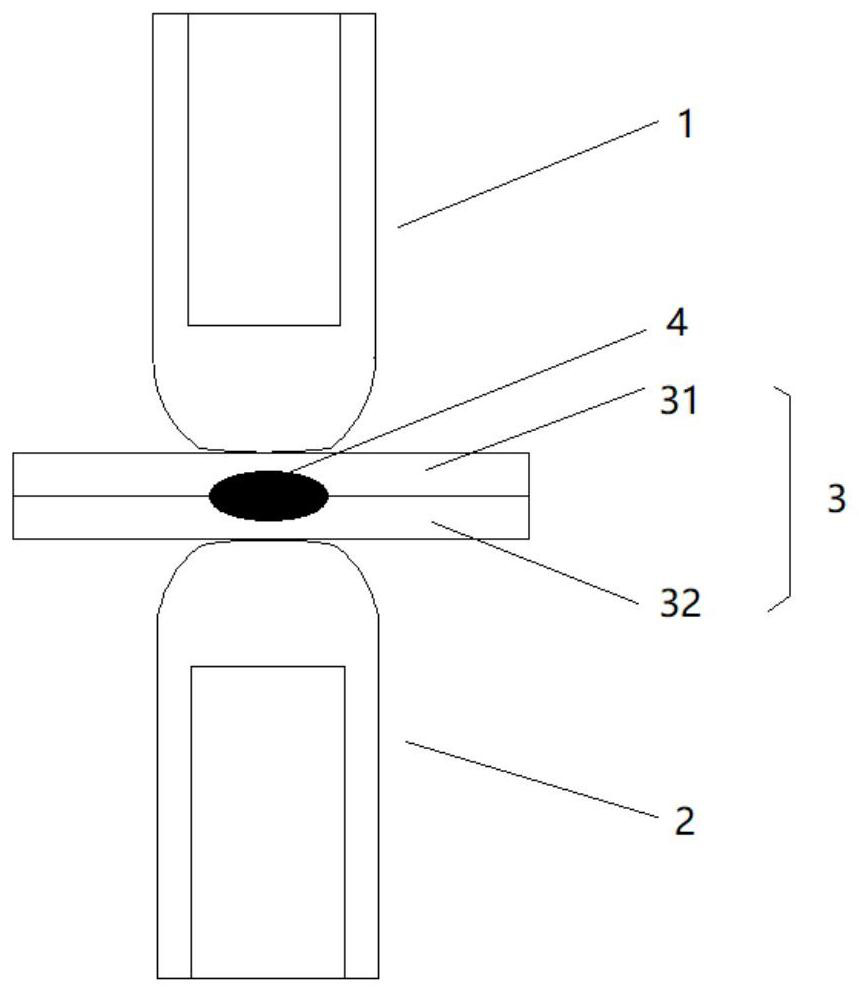

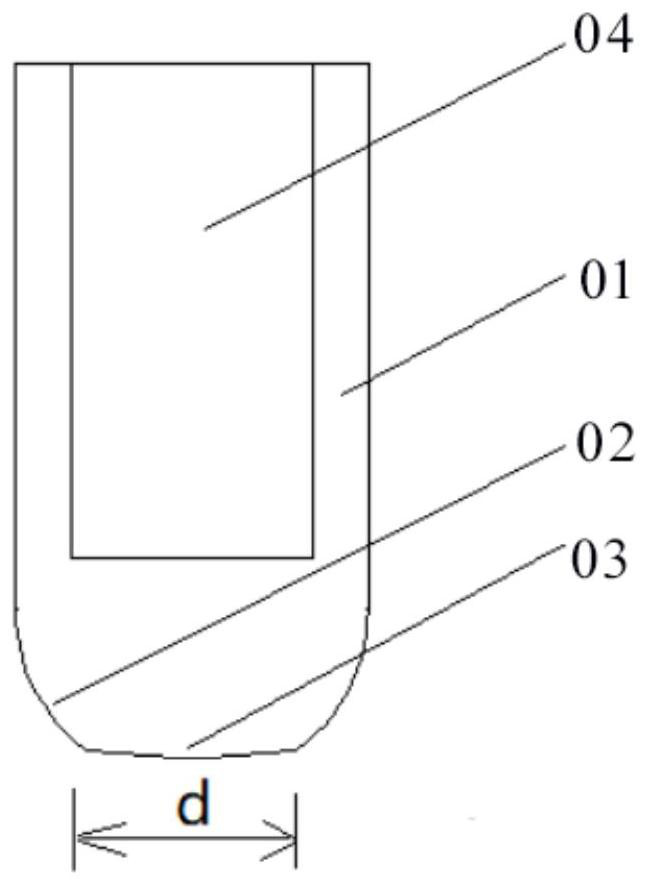

Melting zone control method based on electric melting connector real-time temperature field data

ActiveCN110789133AImprove discriminationEasy to graspPipe connection arrangementsTubular articlesPipe fittingEngineering

The invention relates to the electric melting pipe fitting welding quality evaluation technology, and aims at providing a melting zone control method based on electric melting connector real-time temperature field data. The melting zone control method comprises the steps that welding parameters are utilized for constructing a temperature field calculation model of an electric melting connector; welding process control parameters of the electric melting connector are input into an electric melting welding machine, after welding is started, voltage and current data output by the electric meltingwelding machine in real time are measured and input into the temperature field calculation model, and coordinate data and temperature data of any time and any point in the electric melting connectortemperature field are output in real time; coordinate data of all position points in the melting zone are extracted, and the maximum melting zone depth lmax is calculated; and in the welding process,according to the preset melting zone control section and the real-time changing maximum melting zone depth lmax data, the welding process control parameters are adjusted, and control over the electricmelting connector melting zone coverage area is achieved. By means of the melting zone control method, data support can be provided for accident reason analysis, the melting zone control method is suitable for various electric melting connectors produced by different welding machines and pipe fitting manufacturers, and judgment and welding quality grasping are facilitated.

Owner:ZHEJIANG UNIV

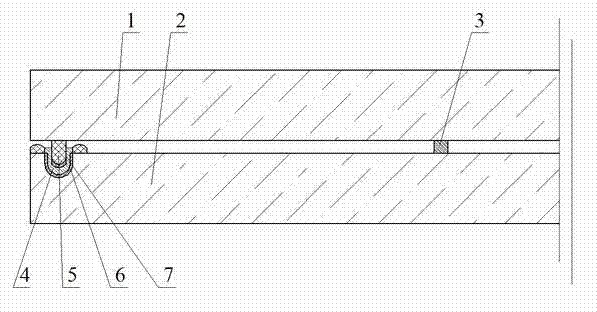

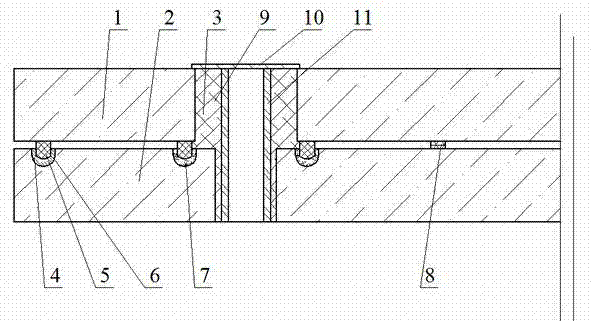

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with at least one sealing strip; the periphery of the lower glass is provided with at least two sealing strips; the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; and after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

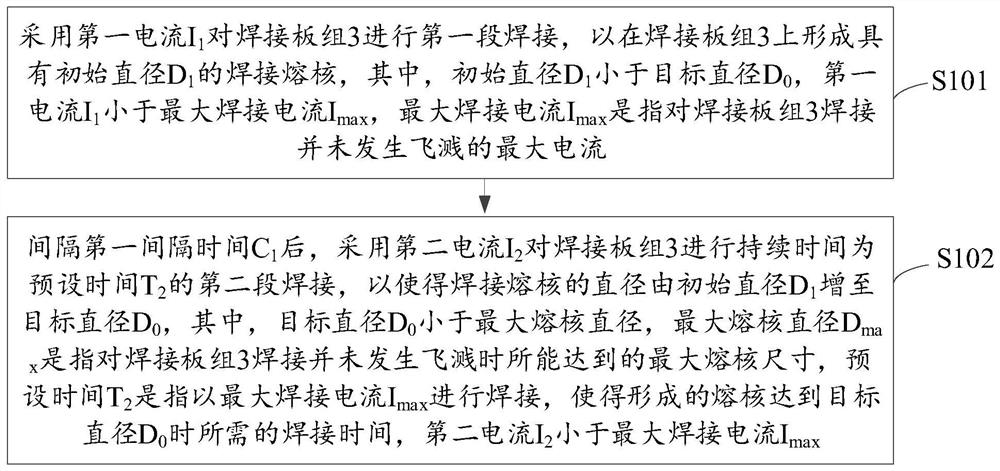

Resistance spot welding method for welding plate group

ActiveCN113134671AShort lifeExtend your lifeResistance welding apparatusElectrical resistance and conductanceSpot welding

The invention discloses a resistance spot welding method for a coated steel plate, and is applied to welding of a resistance spot welding device on a welding plate group. The method comprises the following steps that first-section welding is conducted on the welding plate group by adopting a first current to form a welding nugget with an initial diameter on the welding plate group, the first current being smaller than a maximum welding current; and after first interval time, a second current is adopted for conducting second-section welding with a duration being preset time on the welding plate group, so that a diameter of the welding nugget is increased to a target diameter, the target diameter being smaller than a maximum nugget diameter, the preset time being welding time required when welding is conducted by using the maximum welding current so as to enable the formed nugget to reach the target diameter, and the second current being smaller than the maximum welding current. According to the method, a welding process has a lower welding temperature and shorter high-temperature retention time, and the technical problems that in the prior art, the service life of an electrode is short, and LME cracks exist on the surface of a welding spot of the coated steel plate are solved.

Owner:SHOUGANG CORPORATION

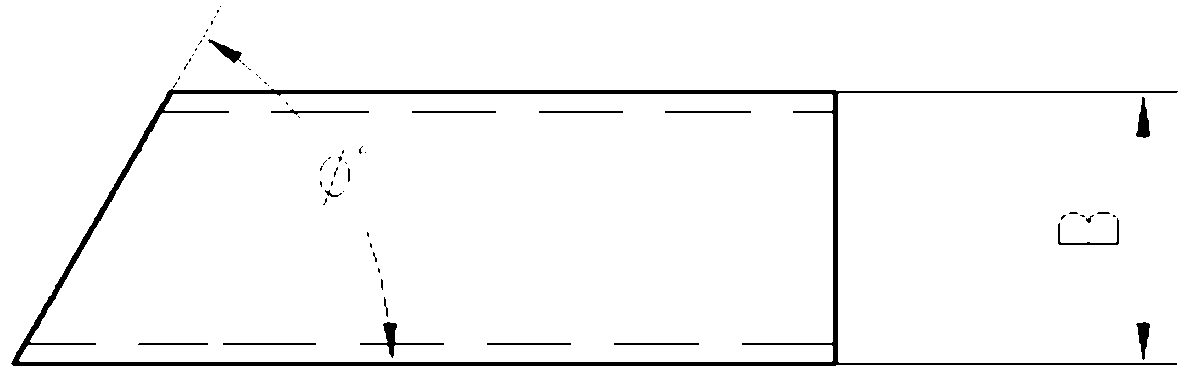

Method for blanking two-sided oblique head structural steel

ActiveCN101961799ALarge butt joint gapLong welding timeMetal sawing accessoriesVehicle frameMaterials science

The invention relates to a method for blanking a two-sided oblique head structural steel, comprising the following steps: 1) manufacturing a structural steel base according to the rotating angle x of the structural steel; and 2) fixing the structural steel on the structural steel base to be tightly clamped; adjusting the cutting angle of a saw blade to be Phi, and cutting to obtain an accurate space angle oblique head. The rotating angle x of the structural steel is that x is equal to tan-1(tanb / tana), wherein, a is the included angle of the vertical plane of the structural steel inclined plane, b is the horizontal included angle of the structural steel inclined plane, and a and b are the known quantity in actual processing; the cutting angle Phi of the saw blade is that the Phi is equal to tan-1(tanb*cosx), wherein, b is the horizontal plane included angle of the structural steel inclined plane, and X is the rotating angle of the structural steel. By adopting the above technical scheme, the method of the invention can acquire the blanking of the accurate space angle of the structural steel (two-sided oblique head), thus solving the blanking difficulty in the vehicle frame production.

Owner:ZHONGTONG BUS HLDG

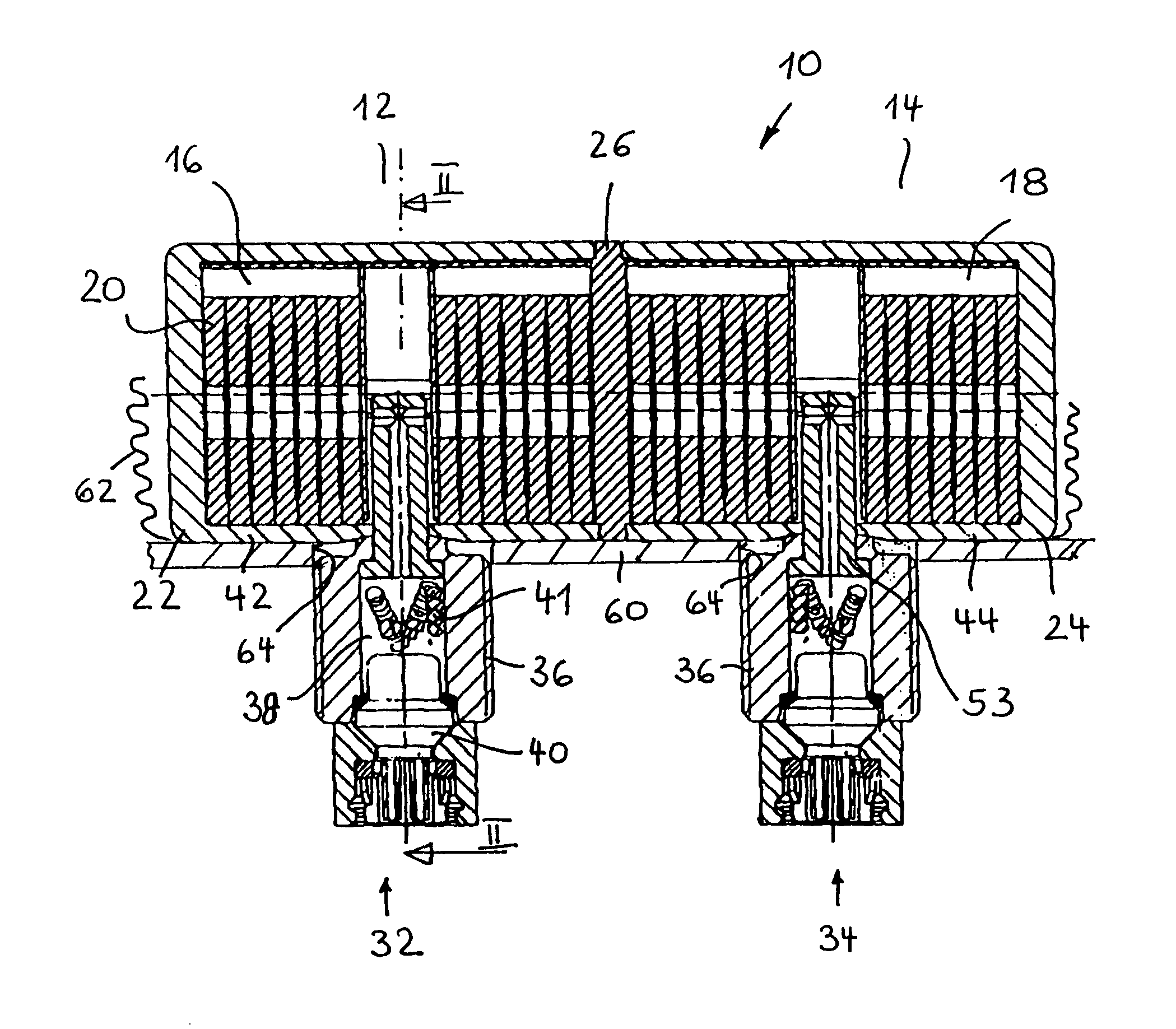

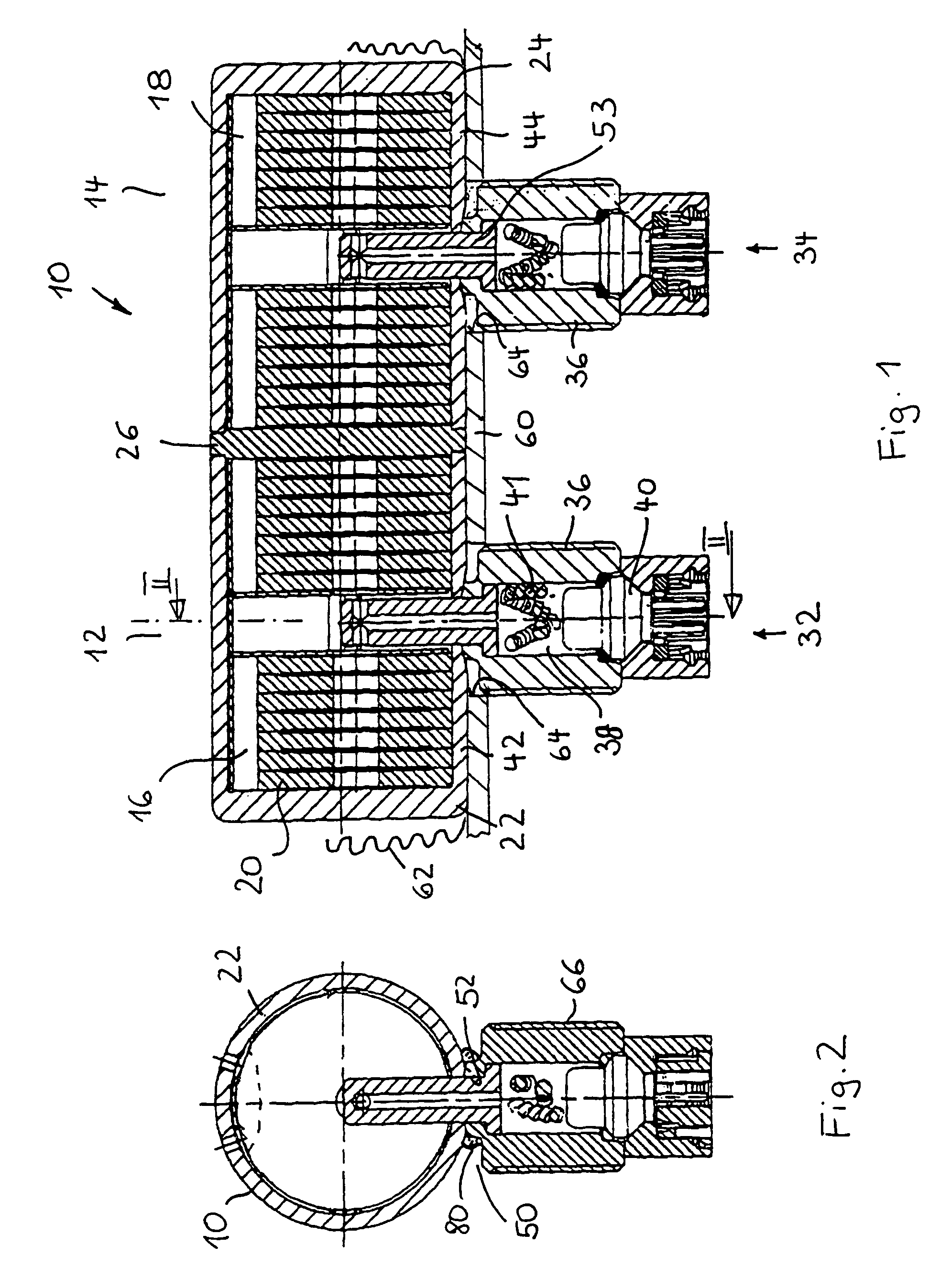

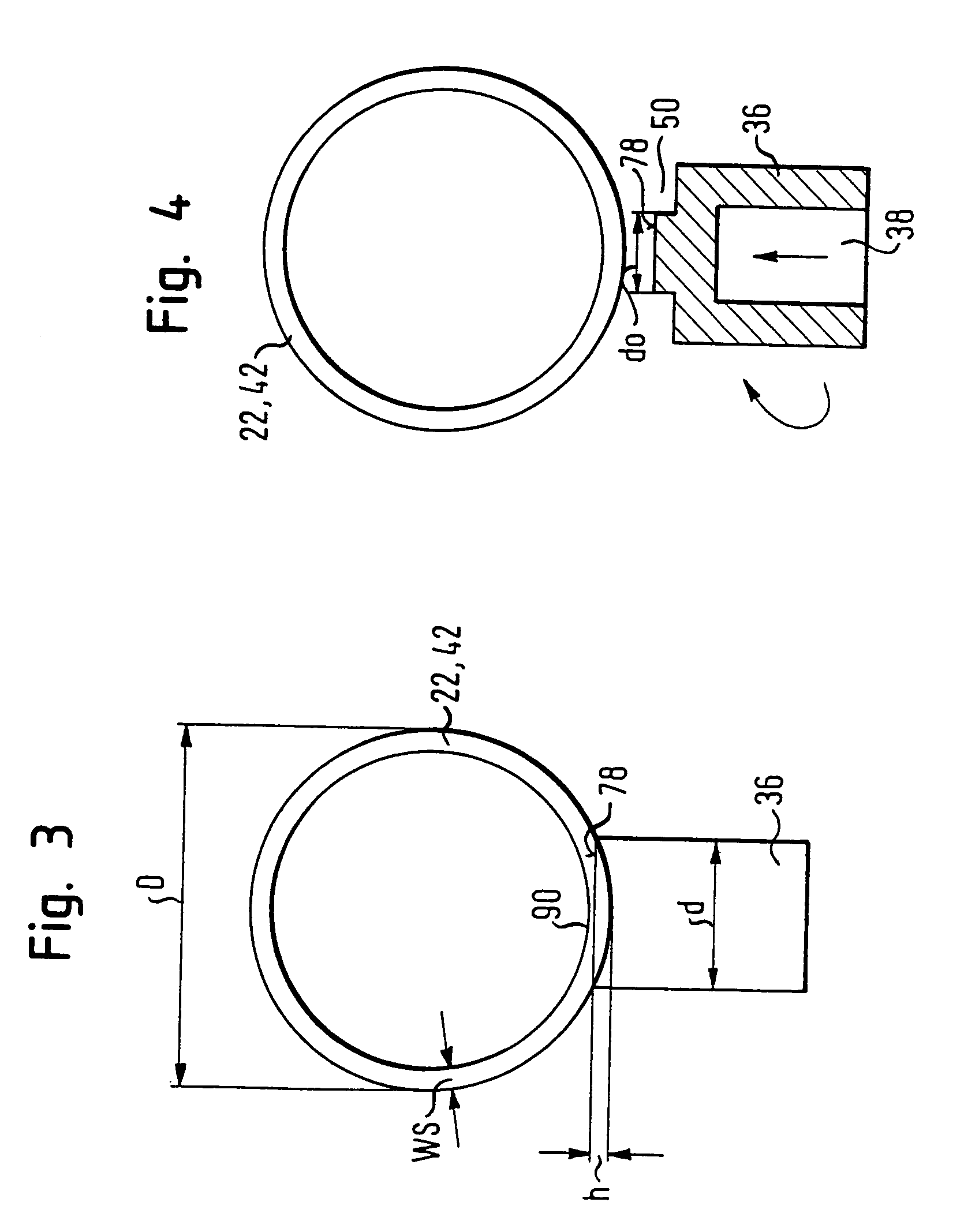

Method of producing a gas generator housing part, gas generator including such housing part and gas bag module

ActiveUS7152321B2Sufficient resistancePrecise and large contact surfacePedestrian/occupant safety arrangementEngine componentsFriction weldingEngineering

A gas generator housing part is produced of a thin-walled tube having a wall thickness which amounts to a maximum of 10% of a tube external diameter and a minimum tensile strength which amounts to at least approximately 800 N / mm2, and a connecting piece having an external diameter which amounts to between 15% and 40% of the tube external diameter. After aligning the connecting piece radially to the tube such that an end face of the connecting piece faces an outer face of the tube, the tube and the connecting piece are joined by friction welding. A maximum welding time amounts to less than 1 second, preferably less than 0.3 second and a friction depth amounts to less than 80% of the wall thickness of the tube.

Owner:TRW AIRBAG SYST

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743805AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

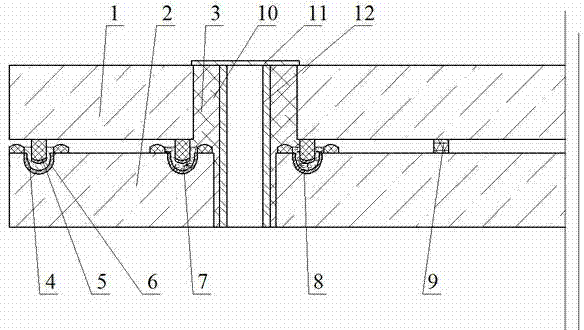

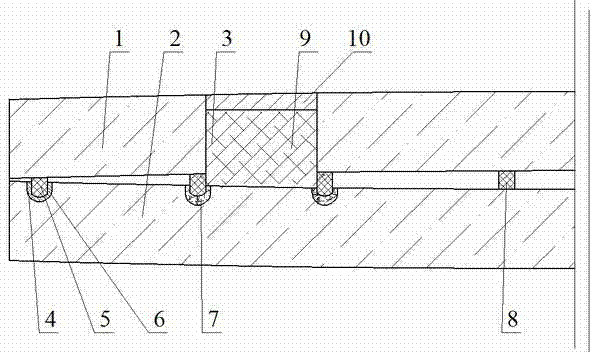

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the periphery of the upper glass is provided with sealing strips; corresponding positions of the periphery of the lower glass are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s)

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace; each air extracting hole is sealed by utilization of metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips and production method thereof

InactiveCN104743850AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

The invention relates to a glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips, which comprises an upper glass and a lower glass, 1-4 extraction openings are arranged on the upper glass, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are respectively provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

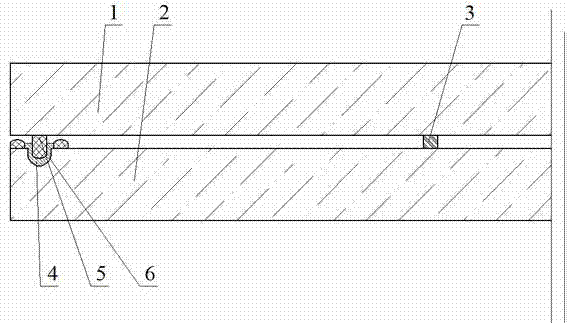

Glass-welded plain vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743832AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass with edges sealed by sealing grooves is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with sealing strips; the periphery of the lower glass is provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

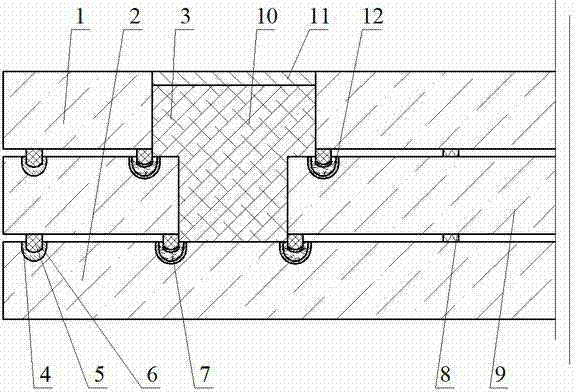

Metal-welded plain double-vacuum-layer glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s)

Metal-welded plain double-vacuum-layer glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace; each air extracting hole is sealed by utilization of metal solder in a vacuum furnace; two sealed vacuum layers are formed among the three sheets of glass; and supports arranged in a point array are disposed in the vacuum layers. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

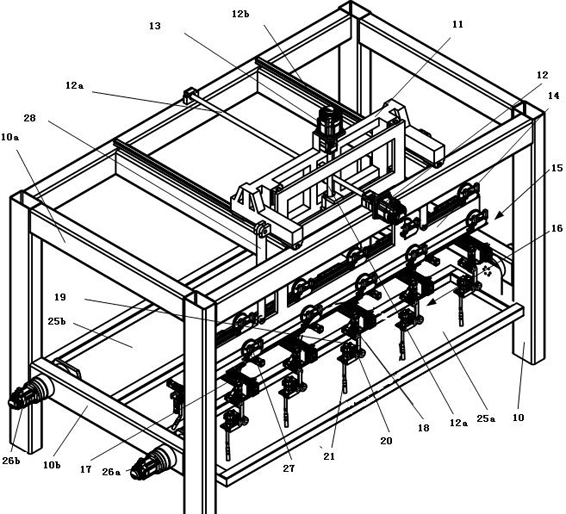

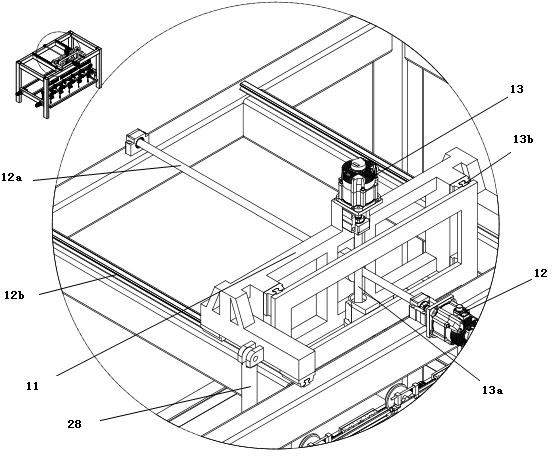

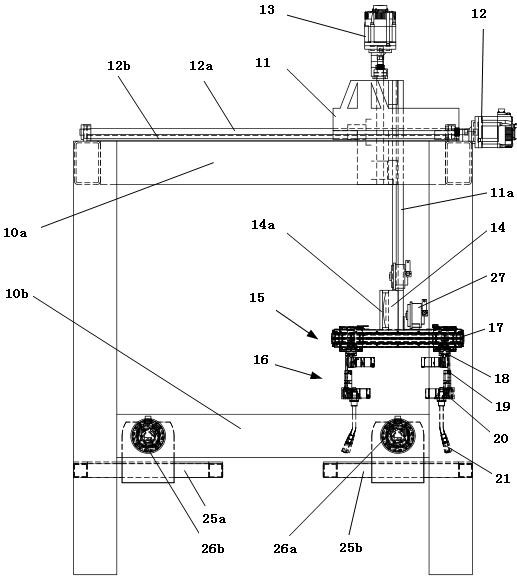

Multi-axis welding machining center

PendingCN113385782AIncrease reachImprove steering flexibilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMachining

The invention discloses a multi-shaft welding machining center and belongs to the field of welding. A multi-direction moving device is arranged on a rack of the welding machining center, wherein a plurality of welding devices are hung below the multi-direction moving device in a sliding manner, and each welding device comprises a linear moving mechanism and one or more welding mechanisms; each welding mechanism comprises a plurality of joints, the joints are connected through connecting arms, and the plurality of joints at least comprise a welding reversing joint and a welding gun reversing joint; a welding gun is arranged below the welding gun reversing joint; two workpiece turnover platforms are arranged on the lower-layer rack below the welding mechanisms and are a welding station and a preset station separately; and each welding gun performs welding according to a corresponding welding program configured in a controller according to a welding track. According to the welding machining center, different workpieces or different welding paths can be welded at the same time, so that the labor intensity of workers is reduced, the welding speed is increased, and the welding quality is guaranteed.

Owner:郑品刚

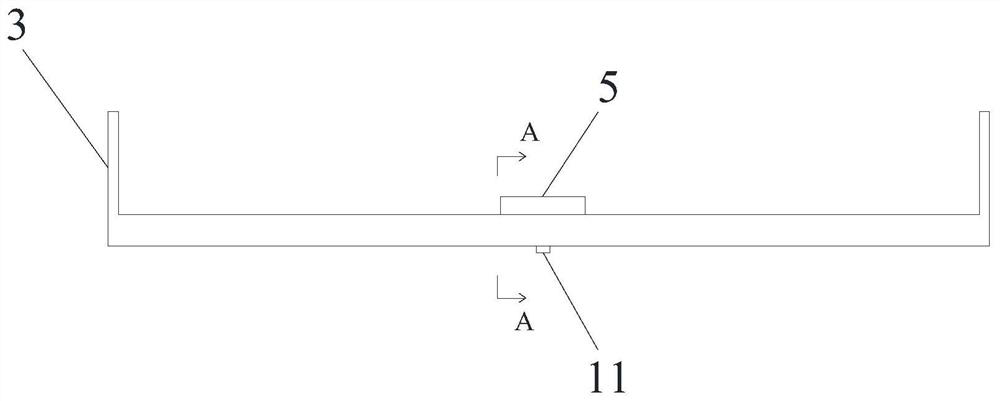

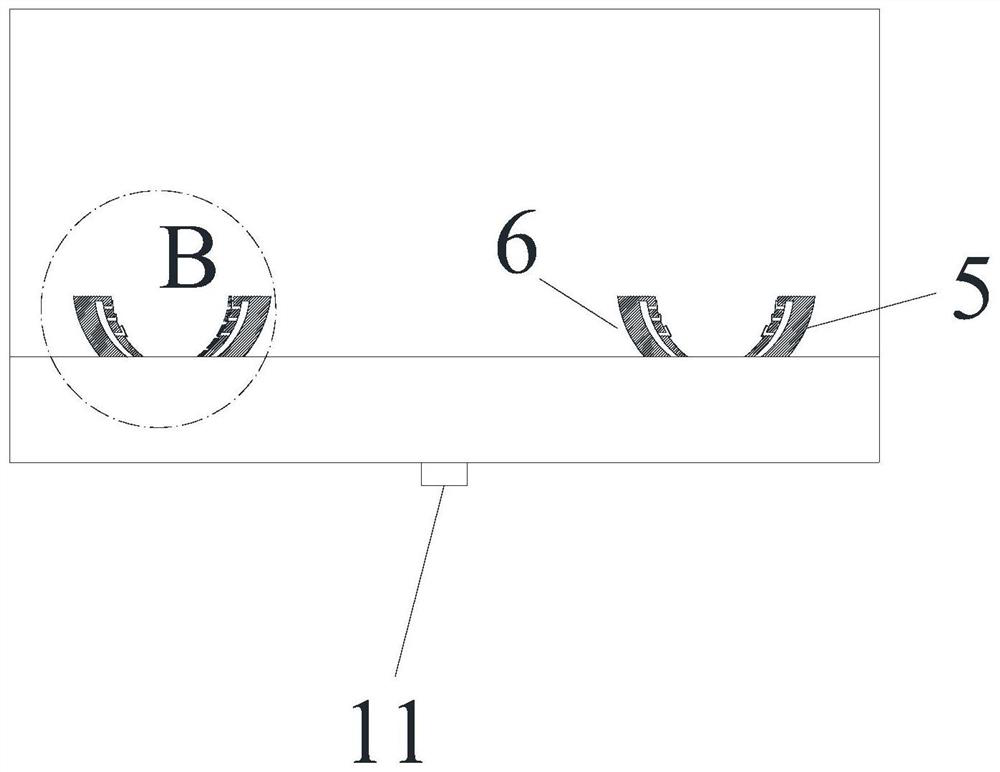

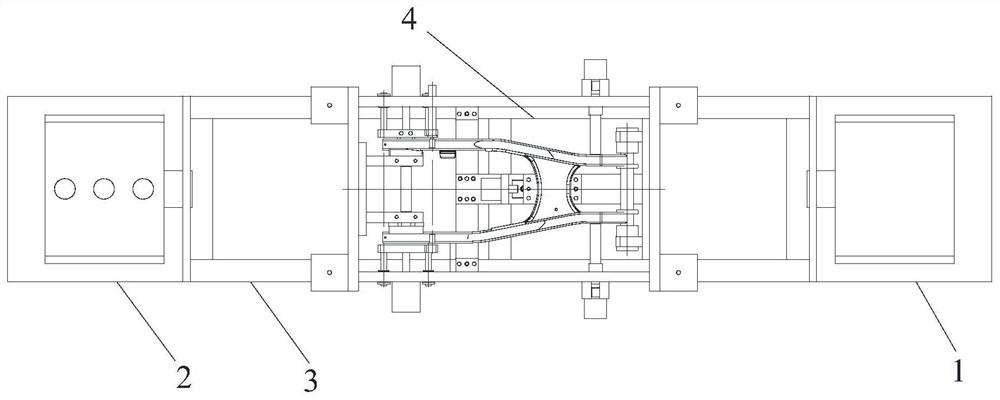

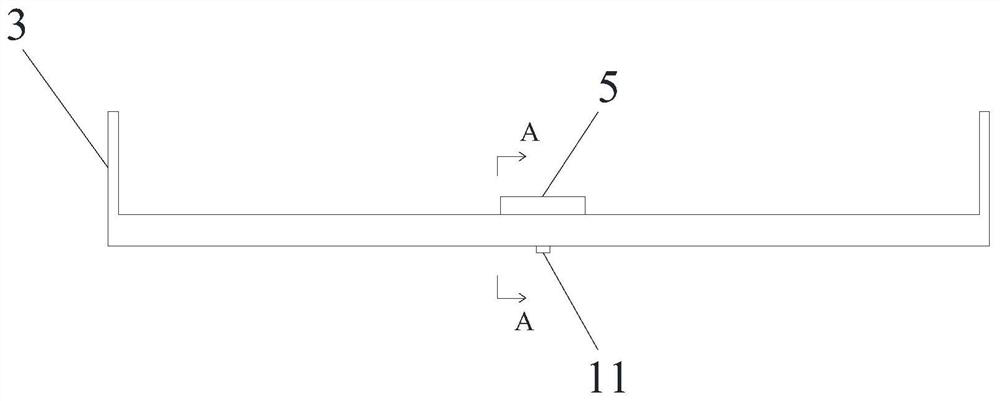

Motorcycle rear fork welding rotating table and welding assembly line

ActiveCN112589326ADiffuse fullyWell formedWelding/cutting auxillary devicesAuxillary welding devicesAssembly lineSupport plane

The invention belongs to the field of motorcycle part production, and particularly relates to a motorcycle rear fork welding rotating table. The motorcycle rear fork welding rotating table comprises afirst supporting body and a second supporting body, a U-shaped supporting frame is arranged between the first supporting body and the second supporting body, an opening of the U-shaped supporting frame is formed upwards, one side of the U-shaped supporting frame is connected with the first supporting body, and the other side of the U-shaped supporting frame is connected with the second supportingbody; and a rear fork fixing tool is arranged on the U-shaped supporting frame, the rear fork fixing tool is connected with the U-shaped supporting frame, and an air guide structure is arranged on the bottom face of the U-shaped supporting frame and corresponds to the welding position of a rear fork. According to the motorcycle rear fork welding rotating table, welding flux can be more sufficiently diffused at the positions of the two sides of the rear fork before solidification, and protruding blocks are not prone to being formed at the welding flux combination position.

Owner:江苏万隆车业有限公司

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743818AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass. The plain vacuum glass is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; one sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

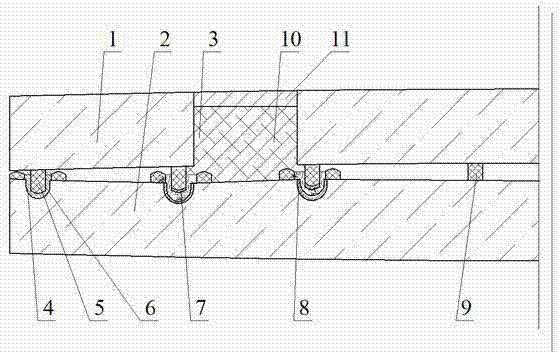

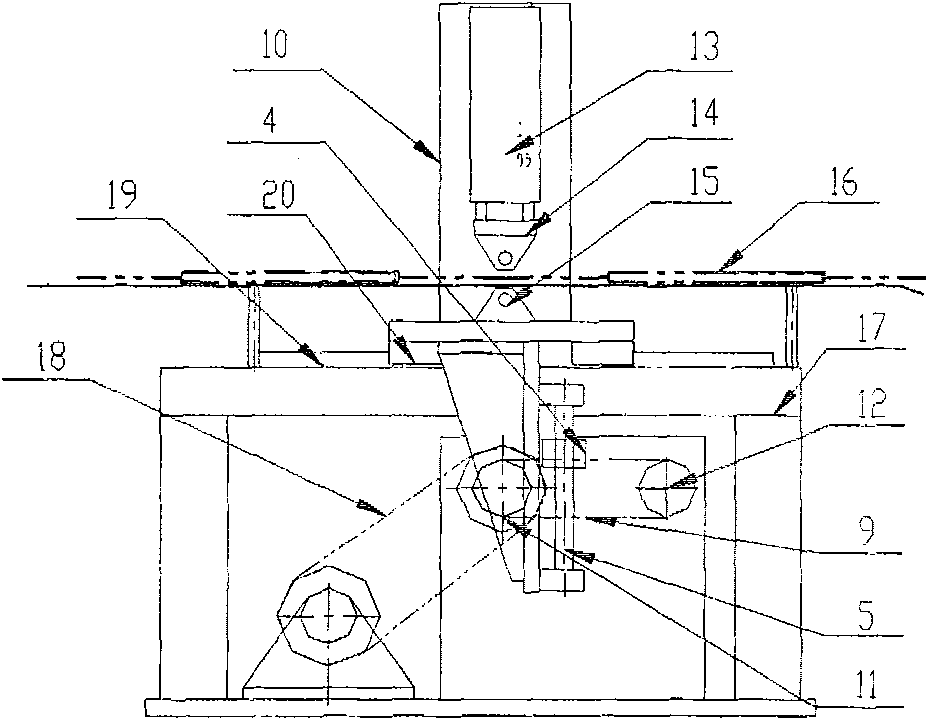

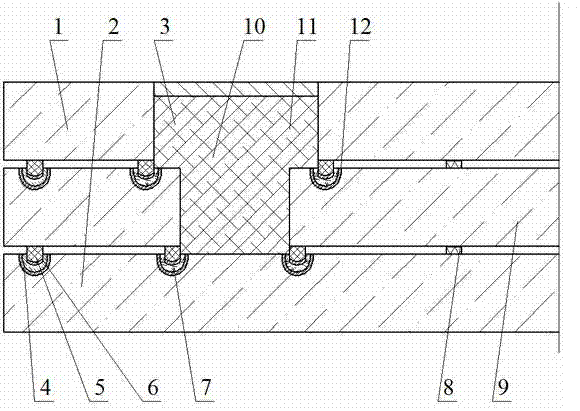

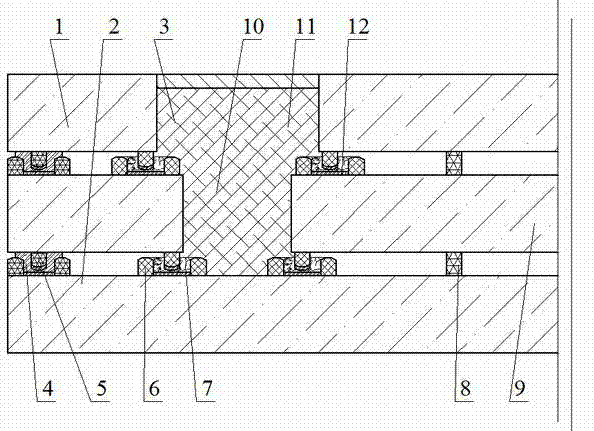

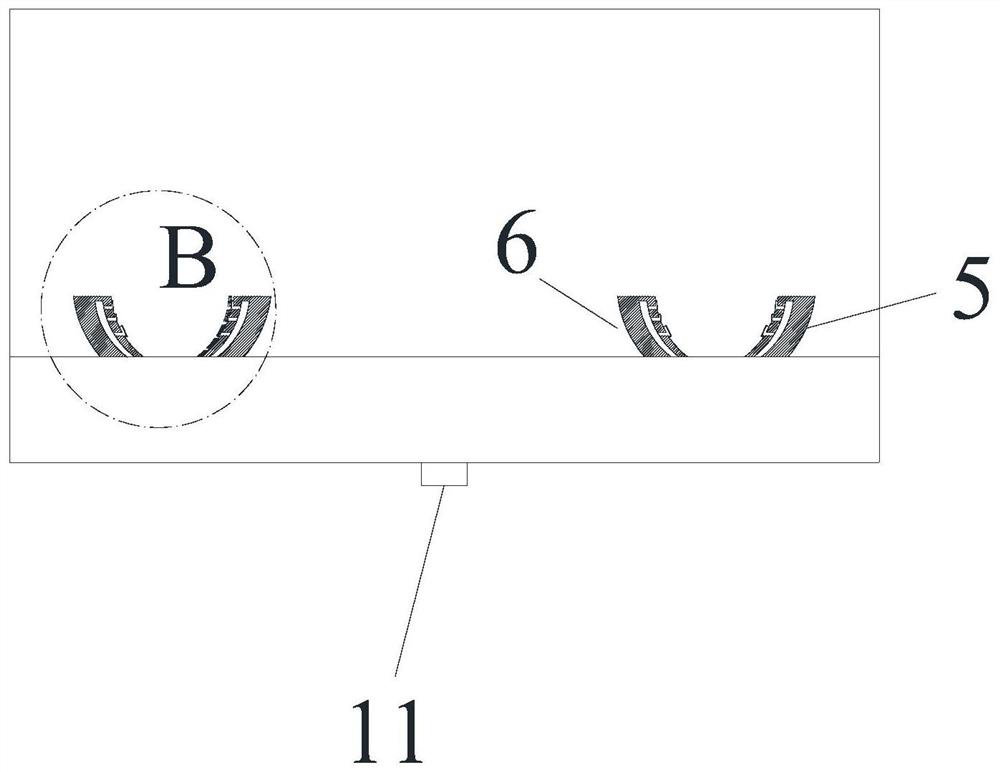

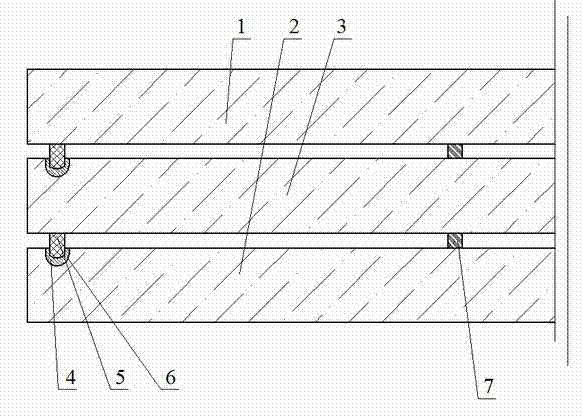

Knife rack driving mechanism for incontinence trousers reciprocating welding system

ActiveCN100581403CRealize planar reciprocating motionLong welding timeClothes making applicancesReciprocating motionWeld strength

The invention relates to a knife rest drive set of a welding system used in the manufacturing process of incontinence trousers. Pivot brackets are arranged on two sides of a sliding bush in a symmetrical way; shafts in the two pivot brackets are matched with two connectors respectively through bearings in a rotating way; two chains are respectively connected with the two connectors; the sliding bush is sleeved on a leader; two ends of the leader are positioned on a leader seat which is fixed on a fixed facility of the leader seat. The drive set has the advantages that firstly, pivot brackets are arranged on the two sides of the sliding bush in a symmetrical way in the knife rest drive set, and the two pivot brackets are matched with the two connectors respectively through the bearings in a rotating way to lead the circular motion of the sliding bush to be transformed to up-and-down movement under the action of the two connectors, thereby realizing the planar reciprocating motion of a mobile welding knife rest, prolonging the welding time of the incontinence trousers, and increasing the welding strength; secondly, no pollutions affect the environmental protection.

Owner:ZHEJIANG YONGCHUANG MACHINERY

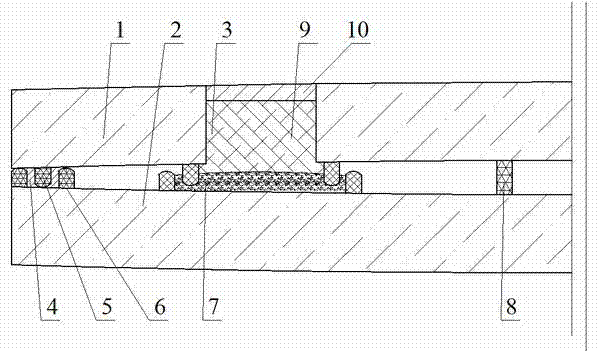

Metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips

The invention relates to a metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through an alloy solder in an atmosphere heating furnace, and the extraction opening is enclosed by using metal solder in vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

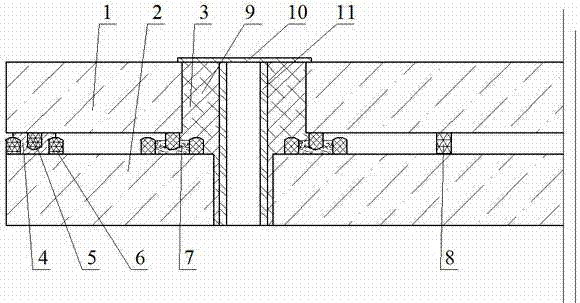

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Method for fixing Velcro connecting piece to automotive pedal pad

ActiveCN101734186BPromote generationShort welding timeVehicle arrangementsVibration amplitudeUltrasonic welding

The invention relates to a method for fixing a Velcro connecting piece to an automotive pedal pad, which is characterized in that: a Velcro connecting component is adhered to the pedal pad to form a whole through a plastic film ring, ultrasonic welding heating is adopted, the obtained heat makes the three welded objects quickly molten, adhered and fixed to the back of the pedal pad, and a clear joint surface of the three, having a grid welding rib concave-convex three-dimensional appearance and high peel strength characteristic, is formed. The film ring is made of polyethylene or other materials, and can cover the surface of the Velcro connecting component or be arranged between the Velcro connecting component and the pedal pad; the thickness of the film ring is between 0.1 and 2mm; and the shape of the film ring is the same as that of the Velcro connecting component, and is a specific figure such as a circle and the like. The welding process adopts the following conditions: the vibration frequency is 30,000-50,000 / second; the welding time is 2-10s; the vibration pressure is 100-300Kpa; and the vibration amplitude of bottom stitches is 0.1-2mm. The method has the advantages of short time, easy control, wide material selection range and no harmful gas.

Owner:上海汽车地毯总厂有限公司

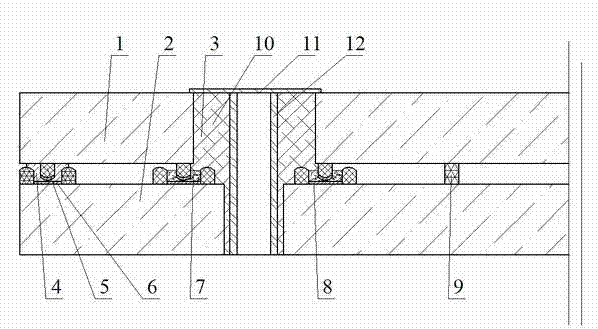

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass which are plain glass. The upper glass and the middle glass are provided with one to four air extracting holes. The periphery of the lower surface of the upper glass, the periphery of the lower surface of the middle glass and the periphery of each air extracting hole are respectively provided with at least one sealing strip. The peripheries of the upper surfaces of the middle glass and the lower glass are provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. Peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. A manufacturing method of the plain double-vacuum-layer glass is simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Rotary Table and Welding Line for Motorcycle Rear Fork Welding

ActiveCN112589326BDiffuse fullyNot easy to formWelding/cutting auxillary devicesAuxillary welding devicesRotary stageWeld line

The invention belongs to the field of motorcycle parts production, and in particular relates to a rotary table for motorcycle rear flat fork welding, which includes a first support body and a second support body, and a U is arranged between the first support body and the second support body. A support frame, the opening of the U-shaped support frame is set upwards, one side is connected with the first support body, and the other side is connected with the second support body, and the U-shaped support frame is provided with a rear fork Fixing tooling, the rear fork fixing tooling is connected to the U-shaped support frame, the bottom surface of the U-shaped support frame is provided with an air guide structure, and the air guide structure is set corresponding to the welding position of the rear fork. The rotary table for welding the rear balancer of the motorcycle provided by the invention can make the solder more fully spread at the positions on both sides of the rear balancer before solidification, and it is not easy to form bumps at the solder joint position.

Owner:江苏万隆车业有限公司

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743833AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the lower surfaces of the upper glass and the middle glass are provided with sealing strips; the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

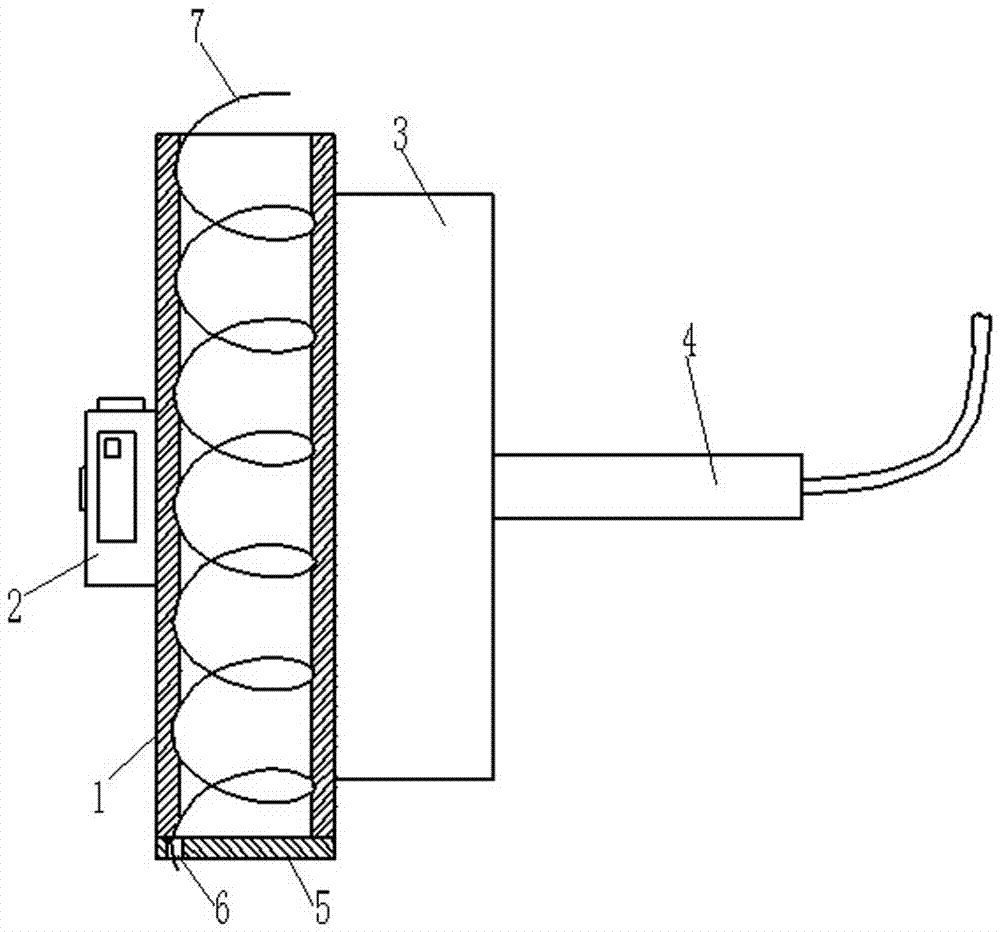

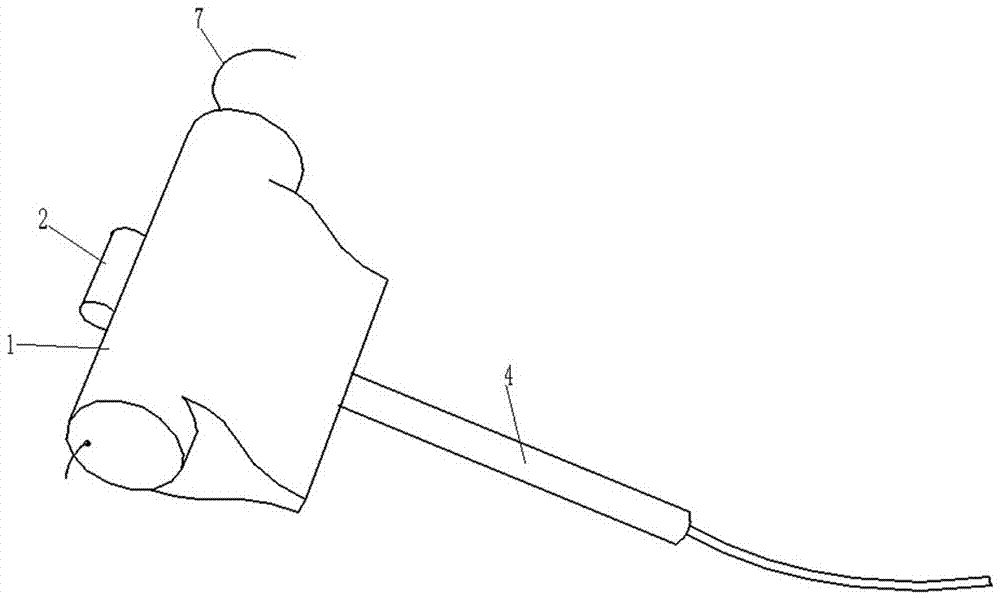

Spiral welding rod and clamping welding gun for same

InactiveCN107309570AMulti-expansion lengthLong welding timeWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringHelix

The invention provides a spiral welding rod and a clamping welding gun for the spiral welding rod. The spiral welding rod is in a spiral shape. The clamping welding gun comprises a column casing, a vibration pump, a reinforcing base and a handle. The inner wall of the column casing is provided with a thread which is in threaded fit with the spiral welding rod. The vibration pump is connected with the outer wall of the column casing. The lower end of the column casing is connected with an end socket. The end socket is provided with a hole. The spiral welding rod penetrates through the hole. The spiral welding rod has the beneficial effects that the welding time of the single welding rod can be prolonged, the welding gun adapting to the welding rod is developed, the unique welding rod and the unique welding gun are cooperated for use, and the welding efficiency is further improved.

Owner:NANTONG HAOTAI WELDING MATERIAL CO LTD

High-temperature-sheet-combination sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743809AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Plain vacuum glass with installing holes by glass welding at sealed edge of sealing strip

InactiveCN104743843AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a plain vacuum glass with installing holes at sealed edge of a sealing strip, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Glass-welded plain vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743834AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with sealing strips; the periphery of the lower glass is provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743828AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

Glass-welded sealed convex vacuum glass with edges sealed by sealing grooves is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting hole. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the lower glass and each air extracting hole are provided with the sealing grooves. After being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com