Melting zone control method based on electric melting connector real-time temperature field data

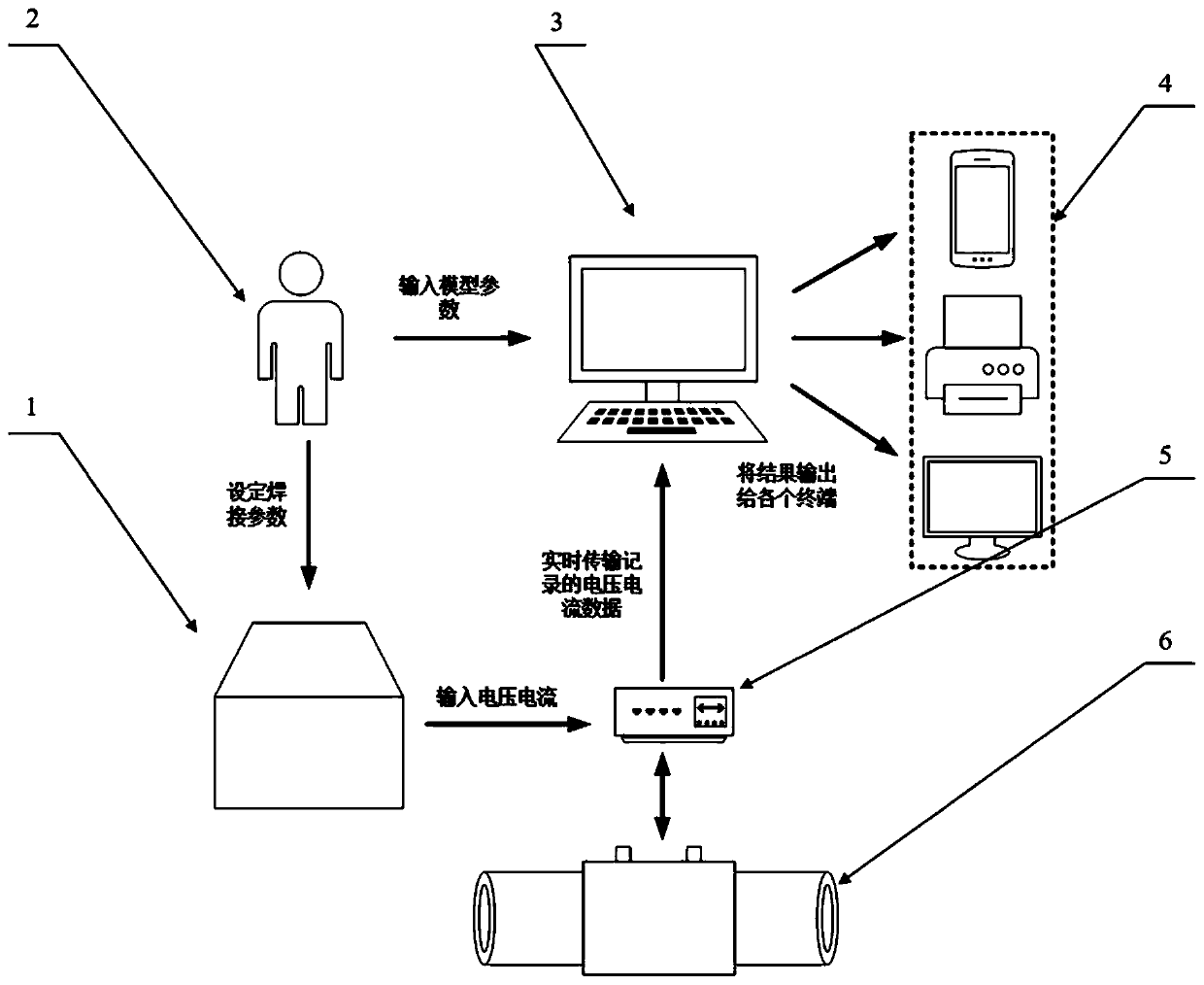

A technology of electrofusion joints and real-time temperature, which is applied in the direction of pipes/pipe joints/fittings, pipe connection layout, household appliances, etc., which can solve the problems of unstable voltage output and inability to analyze the temperature field of the welding process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

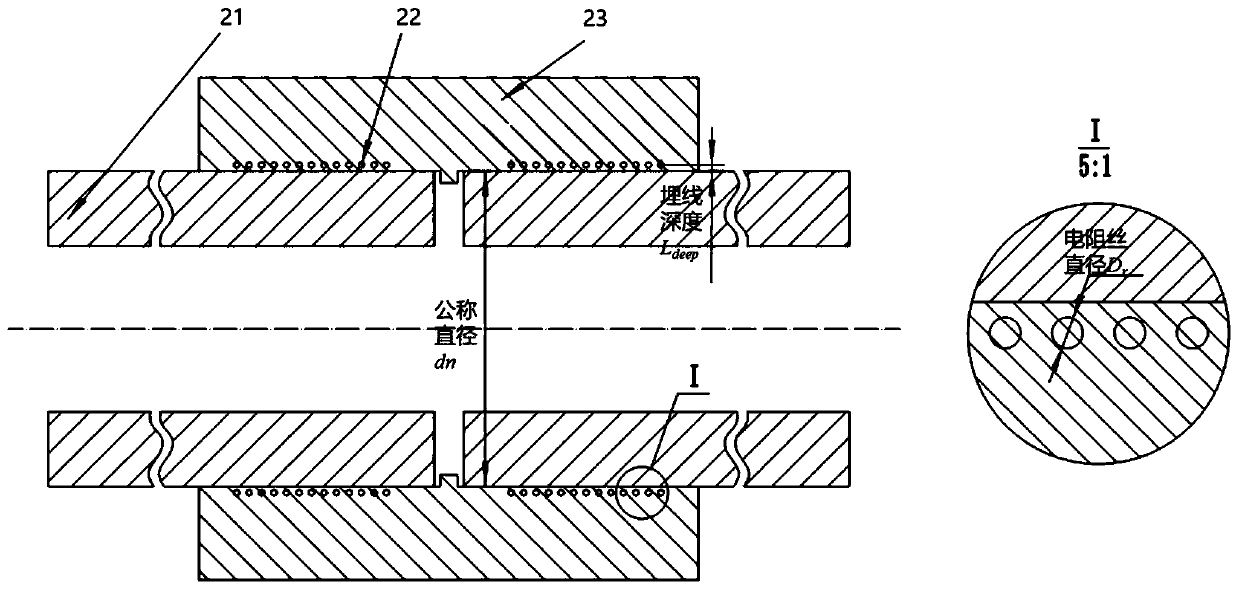

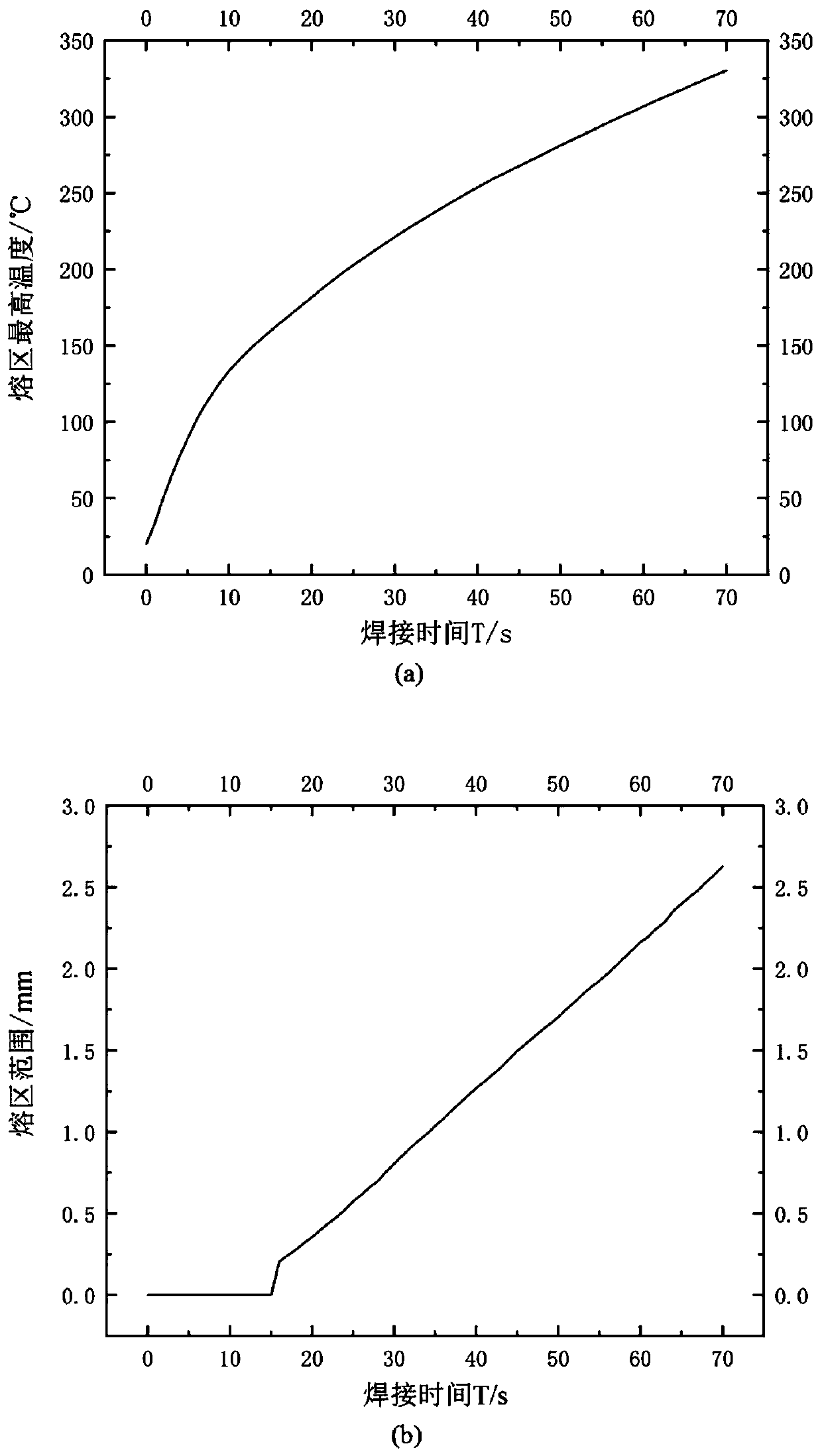

[0099] According to the method for measuring and calculating the temperature field of an electrofusion joint based on real-time welding data provided by the present invention, the temperature field is measured and calculated for an electrofusion joint with a nominal diameter of 63 mm. The nominal diameter of the joint d n 63mm, the total number of resistance wires is 36 (18 on one side), the embedding depth of resistance wires is 0.5mm, the recommended welding voltage is 39.5V, the welding time is 70s, the ambient temperature on site is 20°C, and the standard size ratio The SDR is 11. According to step 1 to step 4 of the method of the present invention, the real-time welding temperature field of the electrofusion joint can be obtained.

[0100] The specific calculation process is as follows:

[0101] 1. The input standard welding voltage in the welding machine is 39.5V, and the welding time is 70s. Apply the known model parameters to the computer.

[0102] 2. Determine the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com