Resistance spot welding method for welding plate group

A technology for resistance spot welding and welding of plates, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of short electrode life and LME cracks on the surface of welded joints of coated steel plates, so as to improve electrode life and avoid LME. Cracks, the effect of saving welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

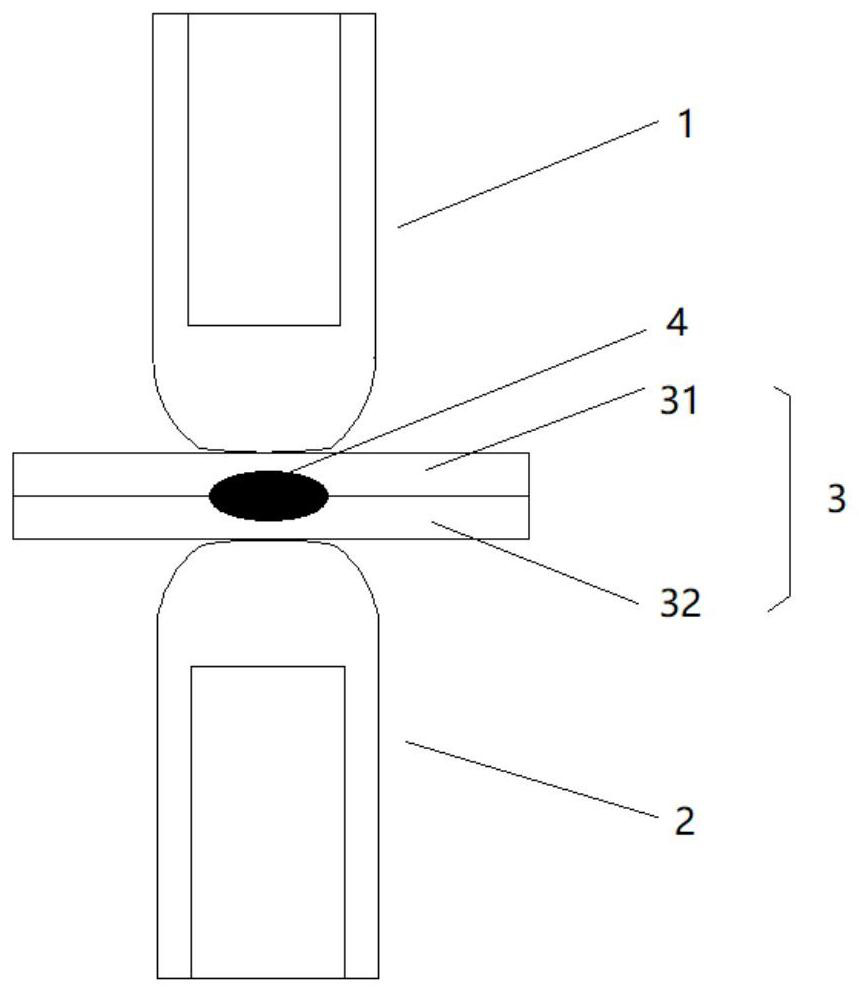

[0078] The top test plate 31 is 1.4mm thick Trip1000, and there are 50 g / m on both sides. 2 The Zn coating, the underlying test plate 32 is 1.4mm thick Trip1000, both sides have 50 g / m 2 The Zn plating layer, by the top test plate 31, the underlying test plate 32 constitutes the welding plate group 3.

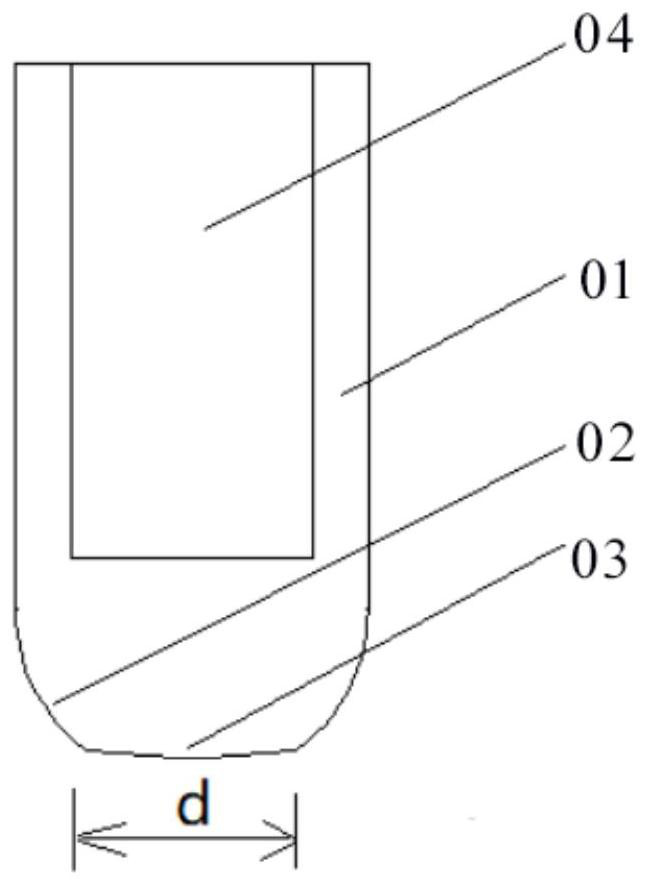

[0079] In response to the characteristics of the weld plate group 3, the upper electrode 1, the lower electrode 2 is the same, the working surface 03 diameter D = 8 mm, the radius of curvature R = 50 mm, the cylindrical region 01 diameter is 20mm, the cooling tank 04 has cooling water, the flow rate is 4L / min.

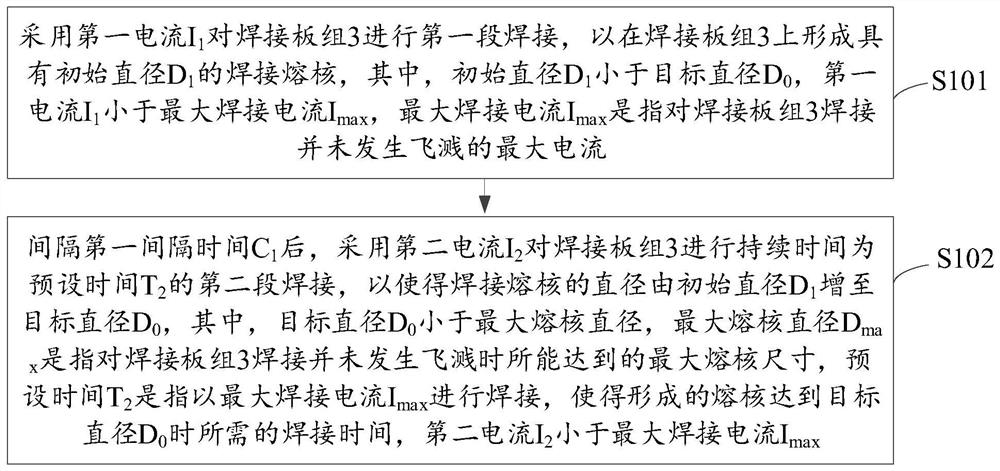

[0080] In electrode pressure N 0 = 4KN, welding time t 0 Under the conditions of 560ms, the splash current I when I have splash occurred. splash = 9.9kA, maximum welding current I max = 9.7kA, at this time, the corresponding melted maximum melted diameter D max = 7.05mm;

[0081] In electrode pressure N 0 = 4KN, maximum welding current I max Under 9.7kA, determine the...

Embodiment 2

[0092] The top test plate 31 is 1.4mm thick Trip1000, and there are 50 g / m on both sides. 2 Zn plating; underlying test plate 32 is 1.4mm thick DP600, 50g / m on both sides 2 Zn plating; from the top test plate 31, the underlying test plate 32 constitutes the weld plate group 3.

[0093] In response to the characteristics of the weld plate group 3, the upper electrode 1, the working surface 03 diameter D = 8 mm of the lower electrode 2 is selected, and the cylindrical region 01 is 20 mm, and the cooling water 04 is cooled, and the flow rate is 4 l / min.

[0094] Since the Trip1000 strength is high and contains residual austenite tissue, the DP600 intensity is low and no residual austenite tissue, so the TRIP1000 welding LME is highly sensitive. Select the upper electrode 1 working surface 03 curvature radius R = 100 mm in contact with Trip1000, and the lower electrode 2 working surface 03 curvature radius r = 50 mm in contact with DP600, the upper electrode 1 working surface 03...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com