Spiral welding rod and clamping welding gun for same

A welding rod and spiral technology, applied in the field of spot welding, can solve the problems of short use time of straight rod welding rod and reduce the efficiency of on-site work, and achieve the effect of improving work efficiency and increasing welding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

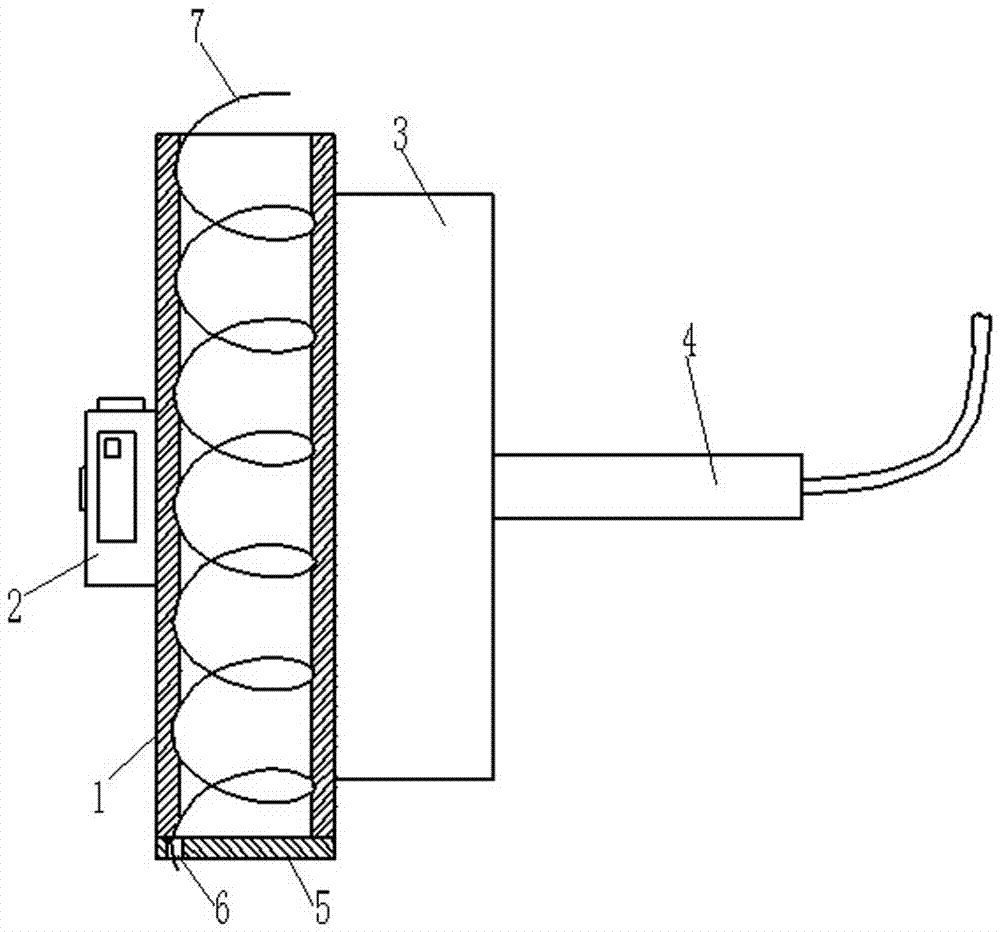

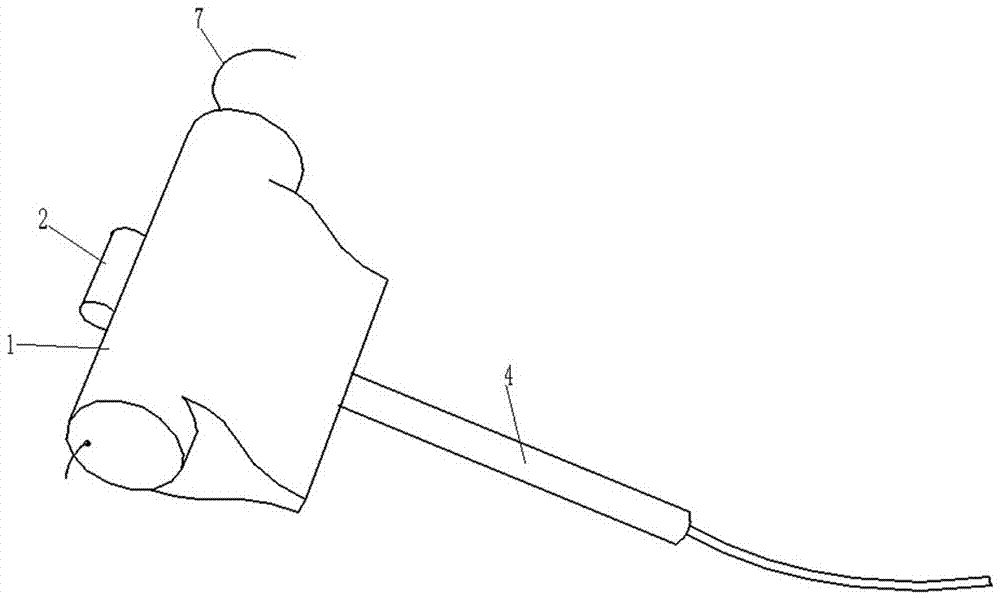

[0011] figure 1 , 2 Middle: cylinder 1, vibration pump 2, reinforcement seat 3, handle 4, head 5, hole 6, spiral welding rod 7.

[0012] A spiral welding rod 7, the spiral welding rod 7 is helical. In this embodiment, the straight electrode is processed into a spiral electrode. This electrode is a slag electrode. By processing the straight electrode into a spiral shape, it is beneficial to increase the welding time and reduce the frequency of welding torch replacement. In the production process, it can save a lot of time for invalid electrode replacement and improve efficiency. The reason is equivalent to the ammunition load of guns. If the ammunition load of guns is increased, then in the actual combat process, the frequency of changing magazines will be reduced. Moment has the advantage of saving lives and winning battles. This comment is a similar metaphor.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com