Multi-axis welding machining center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The motor set in the following two joints is a deceleration motor.

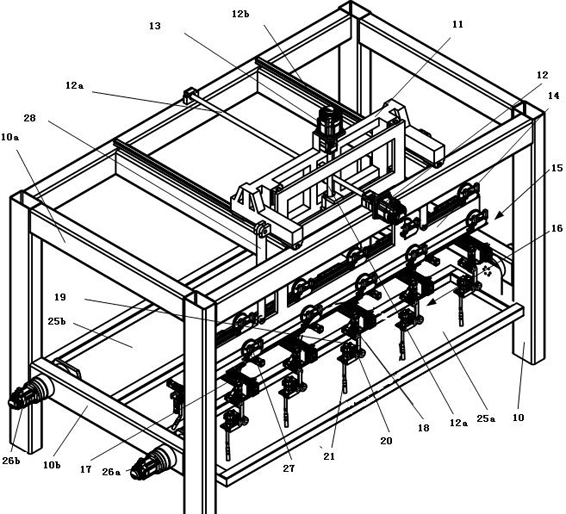

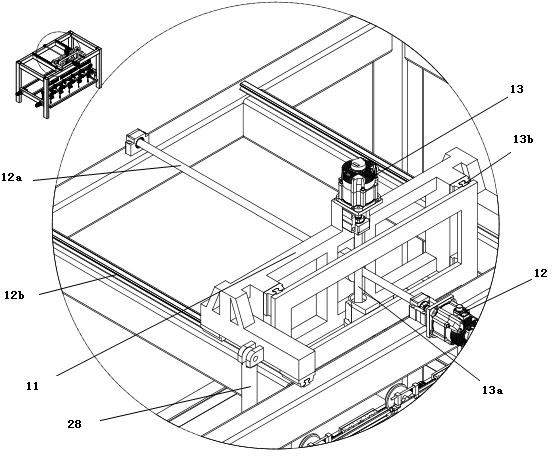

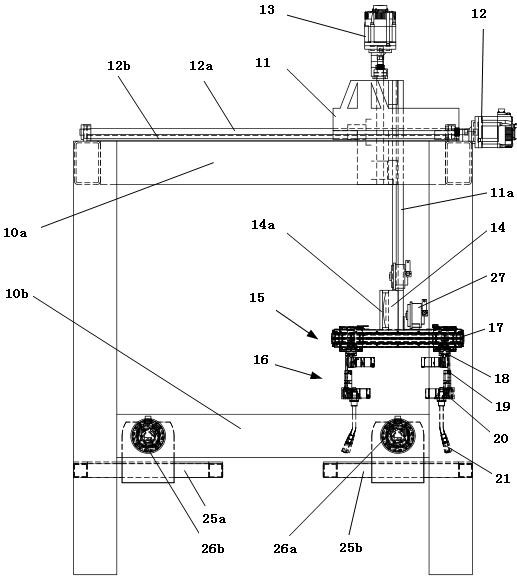

[0026] A multi-axis welding machining center, figure 1It is a general schematic view of the overall structure of the present invention. The multi-axis welding machining center includes a rack 10 including an upper frame 10a and a lower frame 10b, and a multi-directional mobile device 11 is provided by a plurality of sliding mechanisms, and multi-directional mobile device 11 The downward extension 11a is extended downward, and the slide is slid down under the downward extension 11a, and the welding device 15 includes at least a linear moving mechanism and one or more welding mechanism 16, each welding mechanism 16 including a plurality of The joint, the welding mechanism 16 includes at least the welded commutation joint 18 and the weld gun reversing joint 20, and between the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com