Motorcycle rear fork welding rotating table and welding assembly line

A rear flat fork and motorcycle technology, which is applied in the field of rotary table and welding assembly line for rear flat fork welding of motorcycles, can solve the problems of easy breakage, reduce production efficiency, reduce the accumulation of solder in fault parts, etc., and achieve faster heat dissipation efficiency. , The effect of increasing welding time and reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

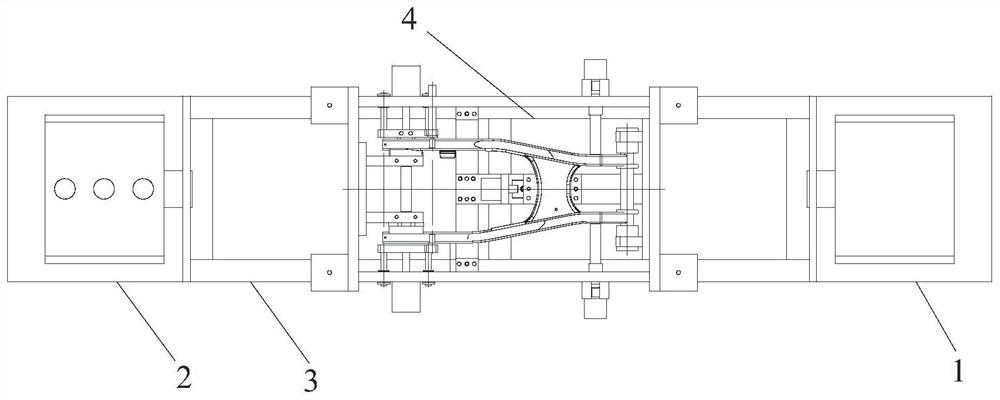

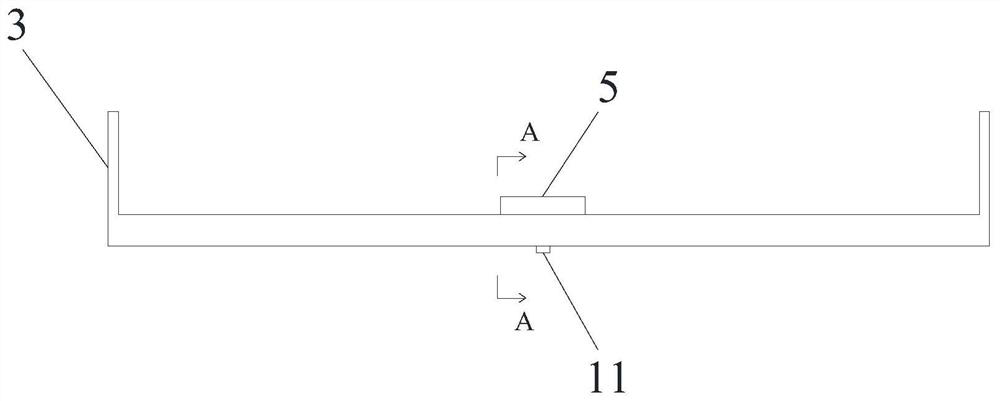

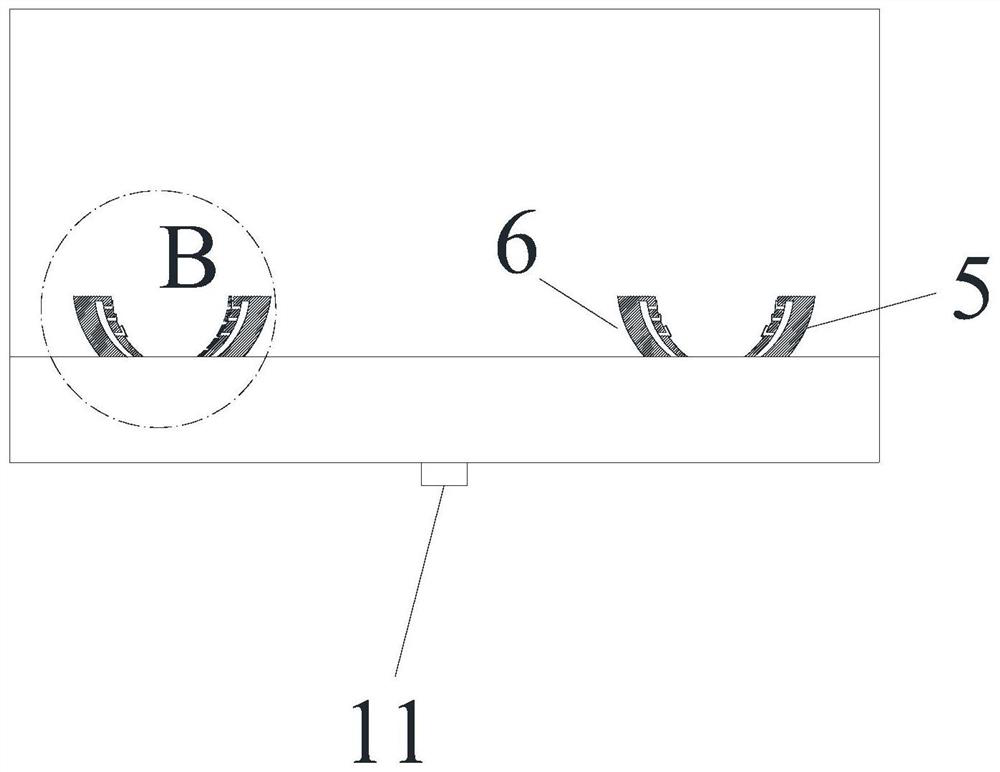

[0023] Embodiment 1, with reference to Figure 1-5 , the present invention provides a rotary table for motorcycle rear fork welding, including a first support body 1 and a second support body 2, a U-shaped support frame 3 is arranged between the first support body and the second support body , the opening of the U-shaped support frame is set upwards, one side is connected to the first support body, and the other side is connected to the second support body, and the U-shaped support is provided with a rear flat fork fixing tool 4, The rear fork fixing tooling is connected with the U-shaped bracket, and the bottom surface of the U-shaped bracket is provided with an air guide structure, and the air guiding structure corresponds to the welding position of the rear fork (that is, after the rear fork fixing tooling is fixed). The welding position of the rear fork when the fork is flat) setting.

[0024] The above-mentioned rotating table for motorcycle rear fork welding is provided...

Embodiment 2

[0028] Example 2, see Figure 7 , the present invention also provides a motorcycle rear chainstay welding assembly line, including a welding robot 21 and two above-mentioned motorcycle rear chainstay welding rotary tables, and two described motorcycle rear chainstay welding rotary tables with welding The robot is set symmetrically based on the base. This design can weld one surface of the rear fork on the rotary table for welding the rear fork of a motorcycle, and then weld the rear fork on the rotary table for welding of the rear fork of another motorcycle. Thereby, time is reserved for the relative motorcycle rear chain fork welding rotary table to turn over and cool the rear chain fork, so that the alternate operation improves the production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com