Method for quenching band spring by using standard jig

A technology of standard templates and leaf springs, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as cycle shortening, acceleration, and unspeakable workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

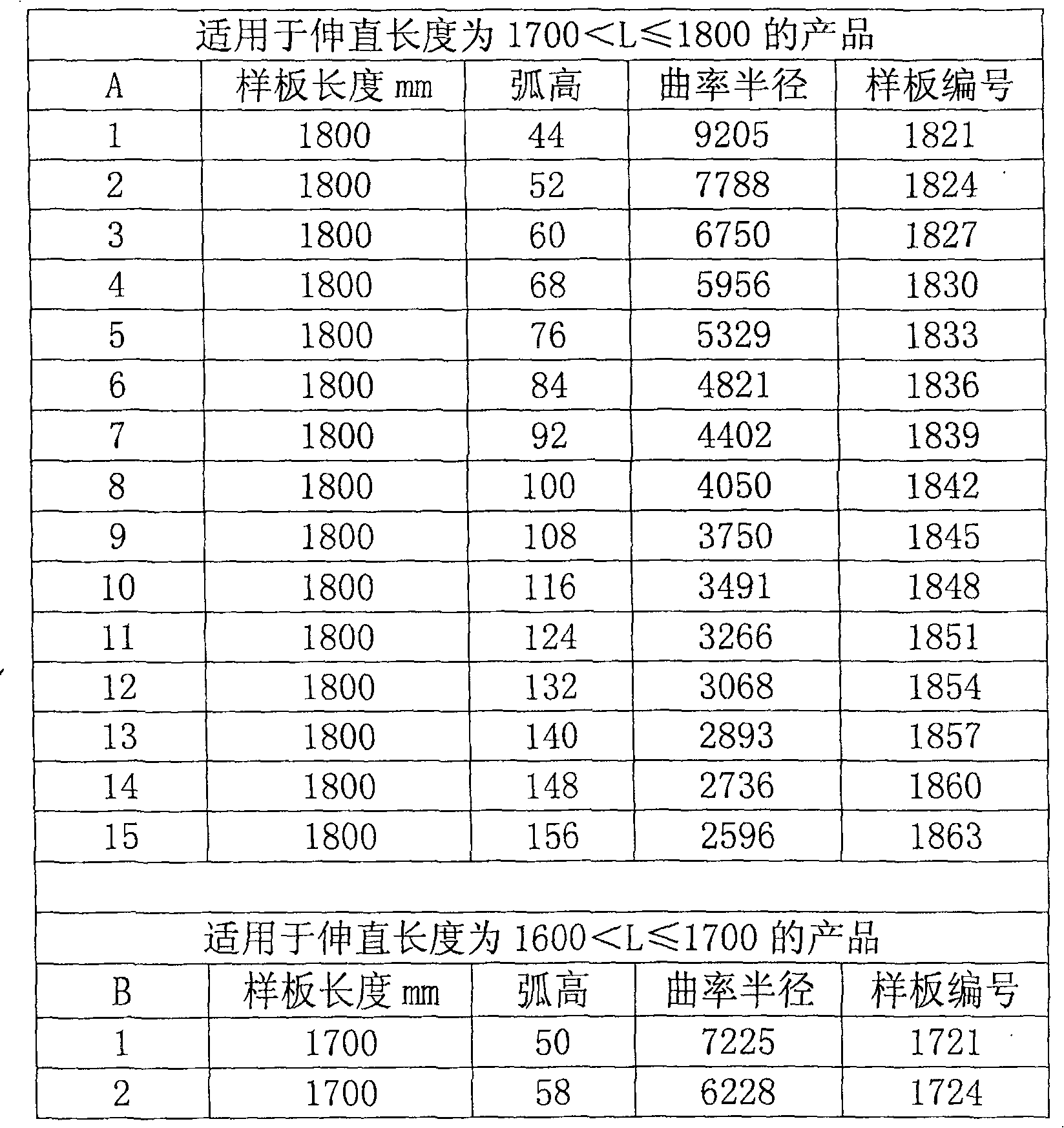

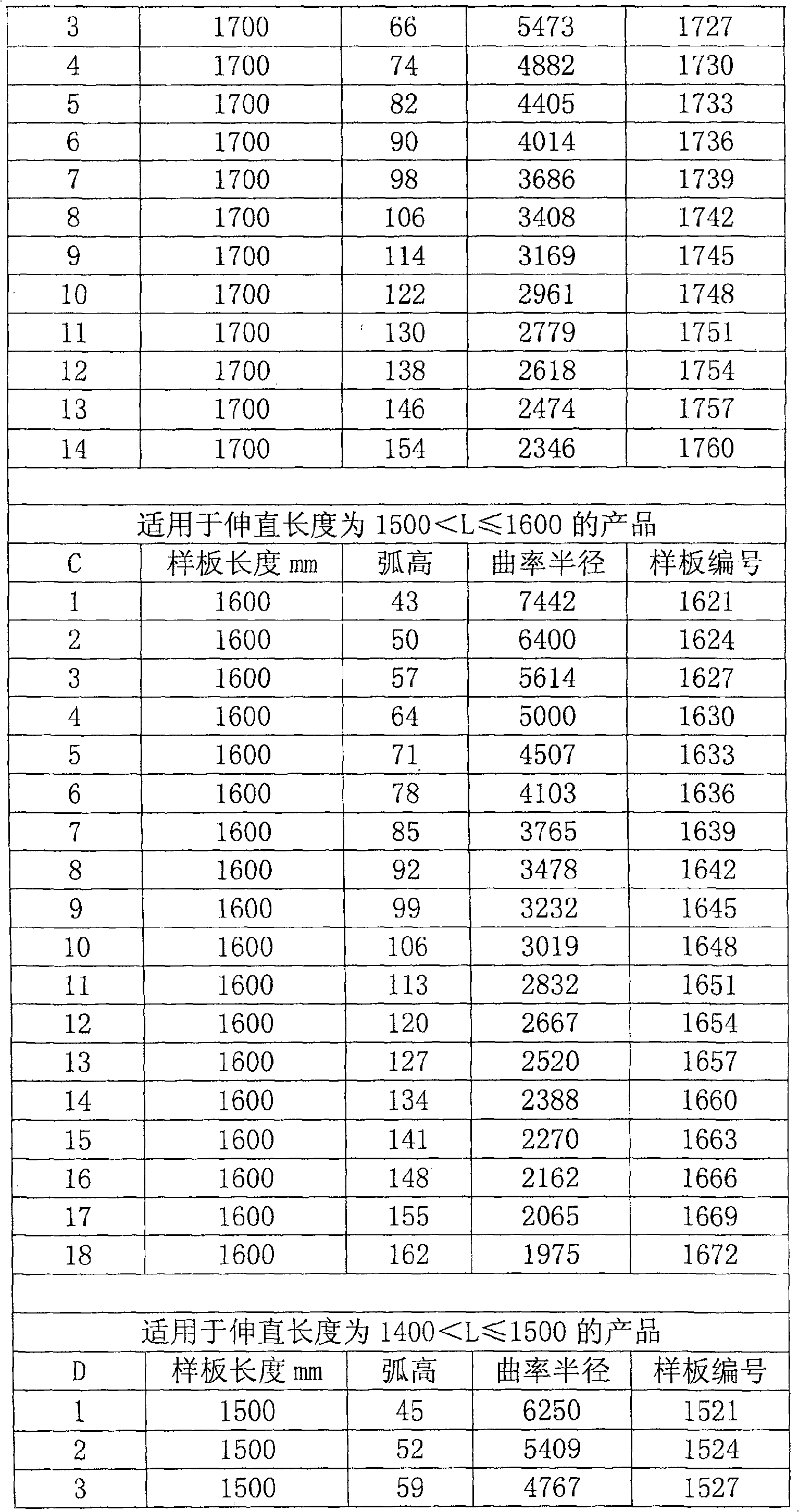

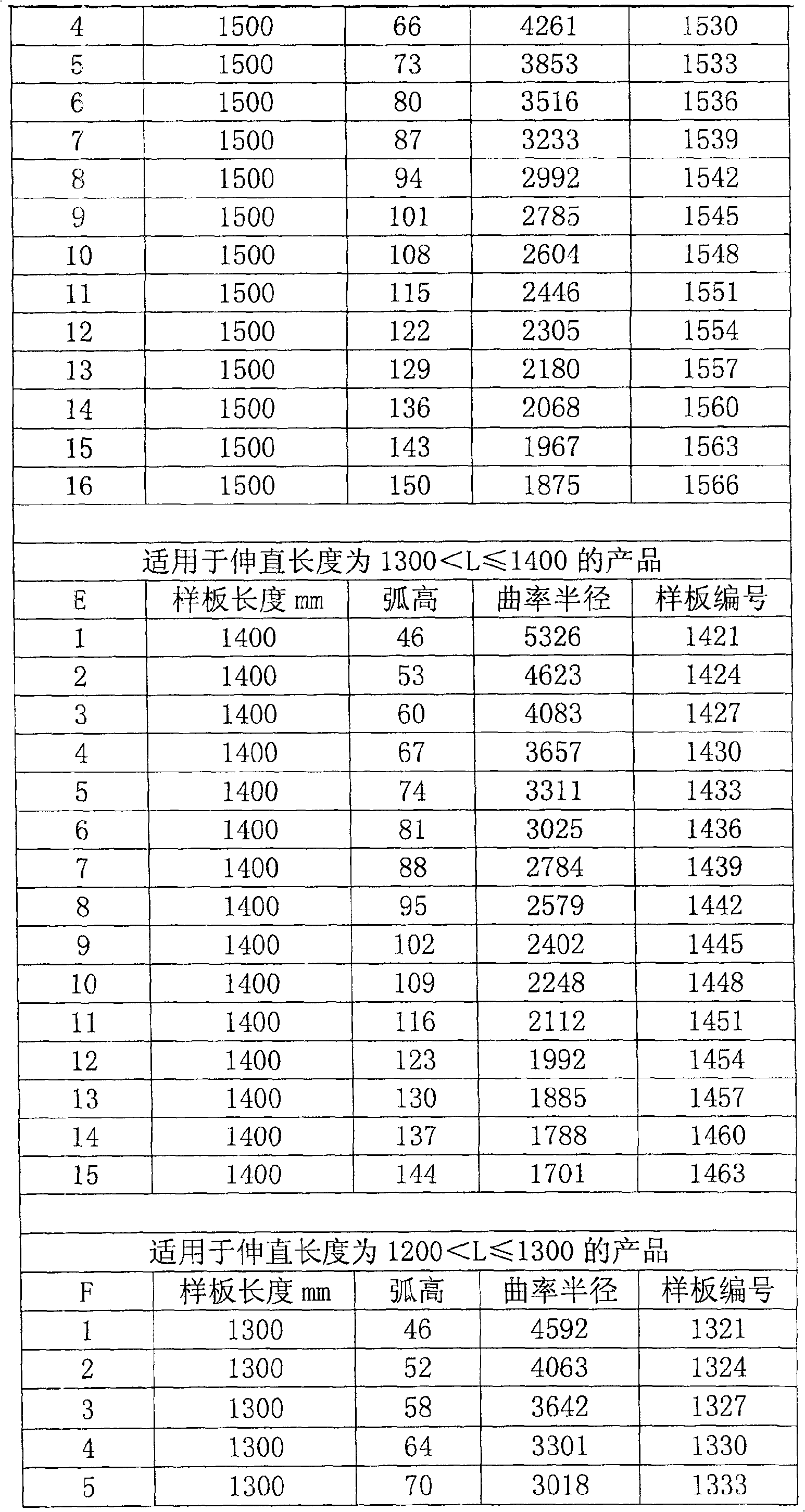

[0008] The standard template of equal cross-section made by this method (unit is MM) can be made of 13×90 double-groove steel plate, and the covering thickness is 9-17 equal cross-section leaf springs. There are 16 kinds of standard lengths, and they are 1800 and 1700 , 1600, 1500, 1400, 1300, 1200, 1100, 1000, 900, 800, 700, 600, 500, 400, 300. The details are shown in Table 1 below:

[0009] Table I:

[0010]

[0011]

[0012]

[0013]

[0014]

[0015]

[0016]

[0017]

[0018] As shown in Table 1, when making a standard model with a length of 1800, the products with a length of 1700<L≤1800 are classified into a large category, and the arc height is summarized, counted and analyzed, and the curvature (or arc height) of the standard model is covered In this summary, the arc height is 44≤H≤156, and the sample is made with a certain distance between the arc heights. Here, a standard sample is made with an arc height every 8mm. When making the standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com