Device for introducing adhesive into a heatable pasting device

A technology of adhesive and accommodating device, which is applied to the device, packaging, labeling machine and other directions for coating liquid on the surface, can solve the problem of not ensuring the placement of the adhesive transport container and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

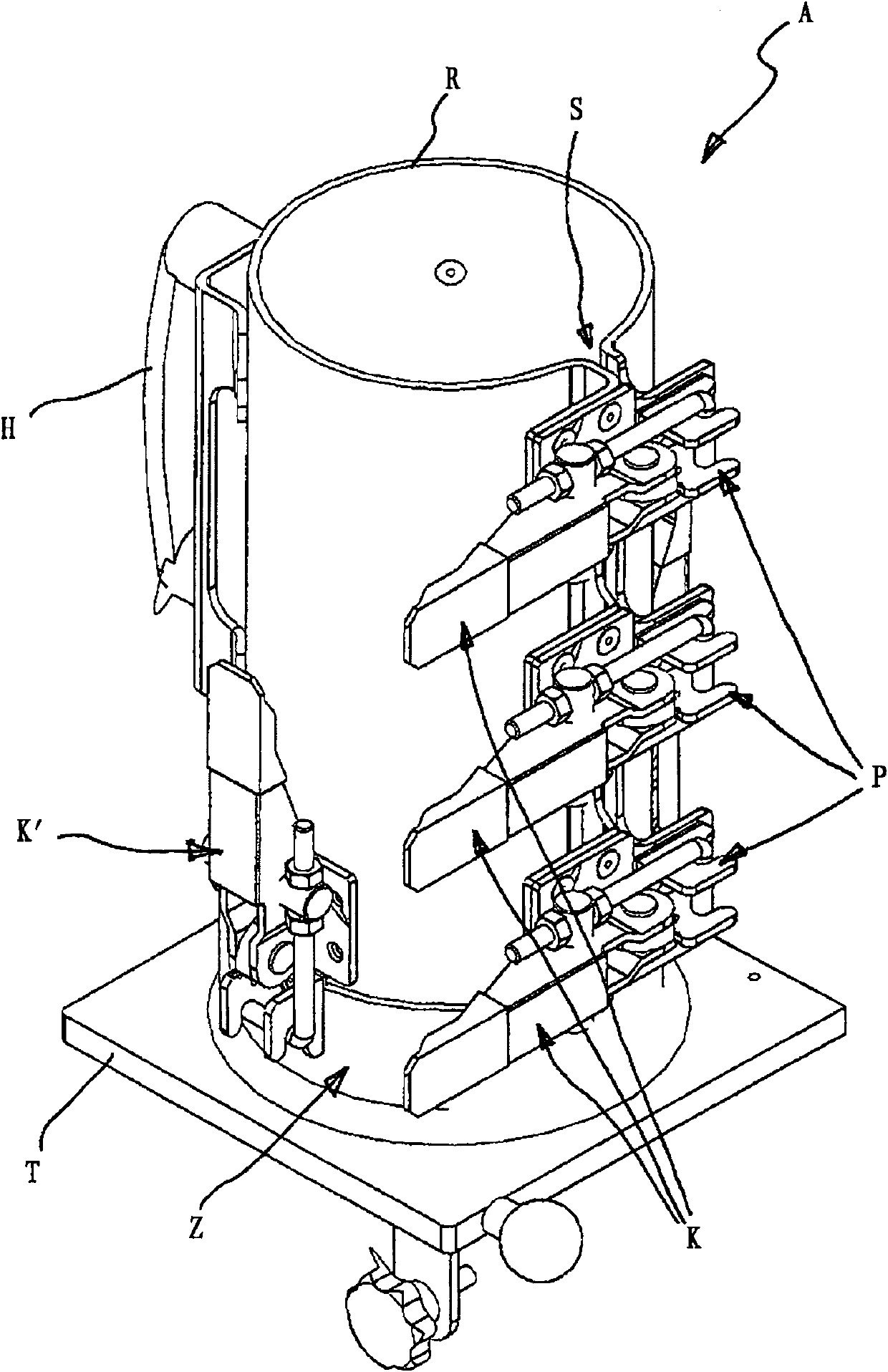

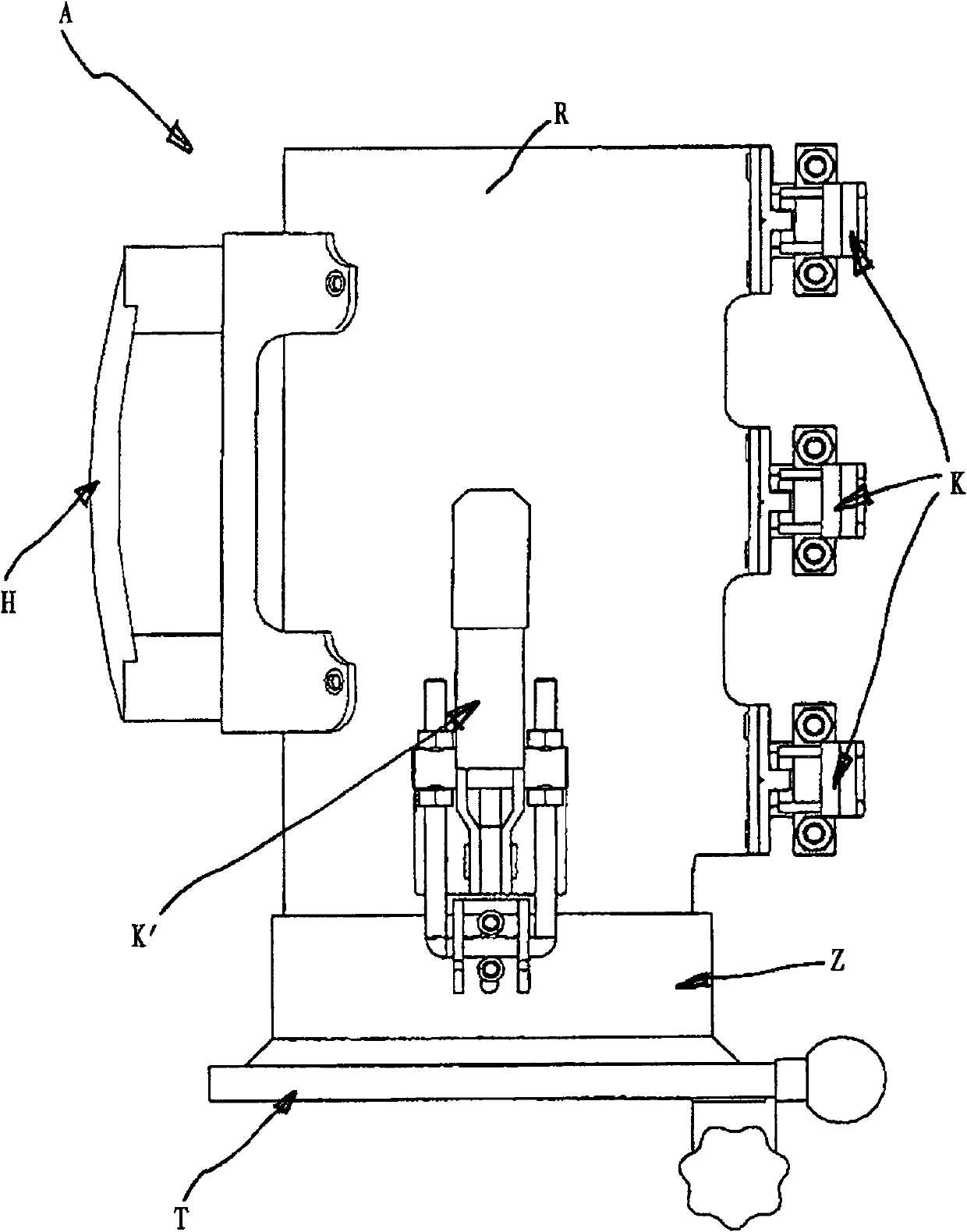

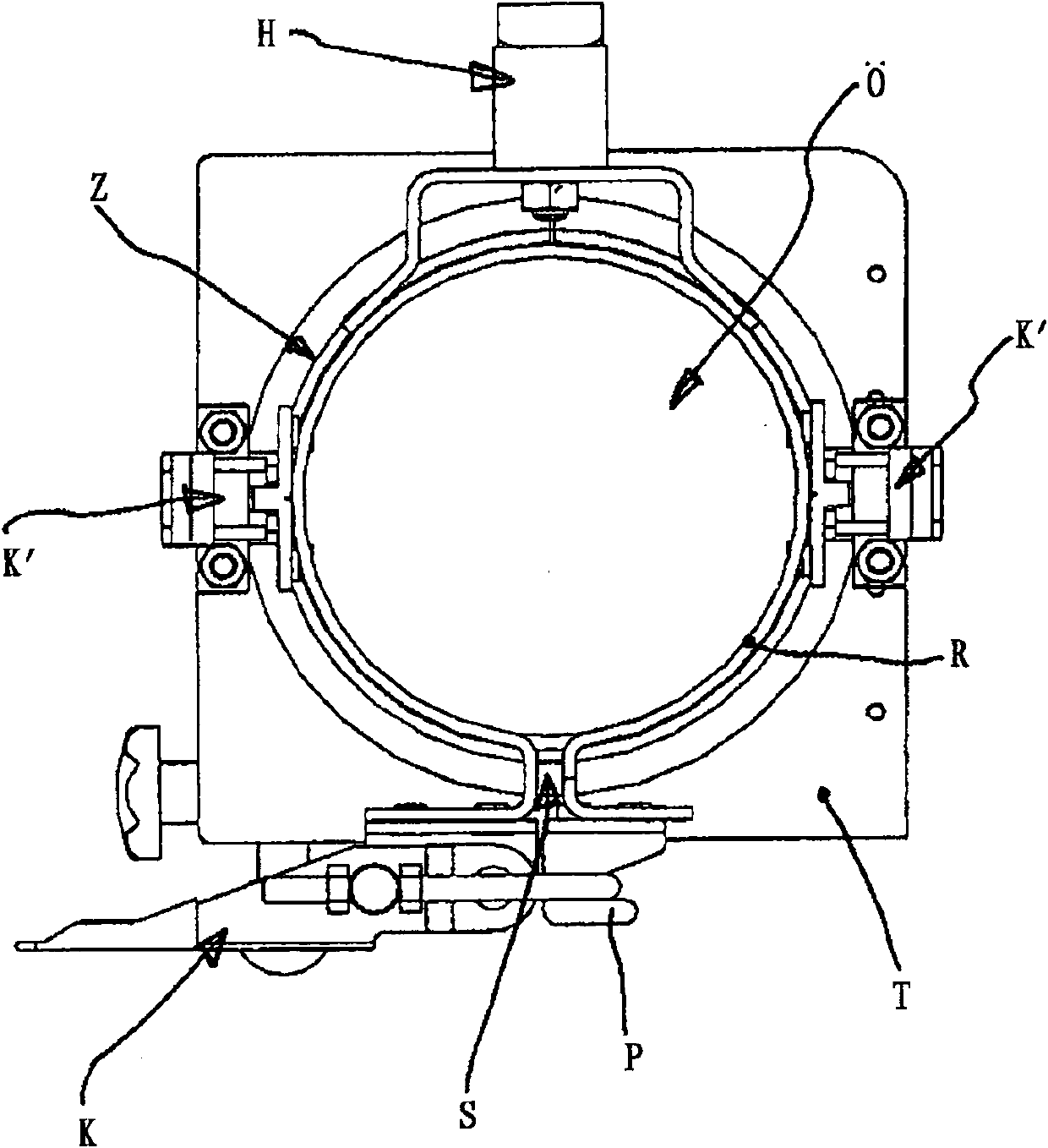

[0016] according to figure 1 The receiving device A basically consists of a tubular body R with a laterally mounted handle H and a support plate T with a centering ring Z. Centering ring Z consists of a image 3 The circular opening in the support plate T shown in

[0017] The support plate T is arranged in a labeling machine for bottles or jars etc., in the Figure 4 Above the filling opening of the storage container V of the gluing mechanism L shown in , for example around a swivel hinge mounted on the upper side. The gluing unit L can be heated by means of an electric heating element E in the storage container V in a manner known per se.

[0018] The tubular body R consists of a circularly curved plate and has a slot S extending continuously over its entire length. The two edges of the plate pointing towards each other at the slot S are each bent outwards in an approximately U-shape and form receiving arms for the toggle quick release K and its clamping hook P.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com