Thin-wall part positioning and machining tool and method

A technology of thin-walled parts and tooling, which is applied in the field of positioning and processing tooling for thin-walled parts, can solve problems such as processing deformation, achieve the effects of eliminating deformation, satisfying the force balance in the horizontal direction, and eliminating part deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The invention is based on the principle of analyzing the positioning and clamping mechanism of the parts, and at the same time, combining the force applied by the tool to the parts, it can estimate the size and action direction of the part causing the deformation force, and adjust the structure of the tooling. The installation and positioning method of thin-walled parts is an important factor affecting its processing quality. The deformation of parts caused by positioning and clamping is a common phenomenon in the machinery industry. The tooling of the present invention and the positioning processing method using the tooling can effectively solve this problem. Eliminate part deformation during machining while achieving integrated machining content.

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

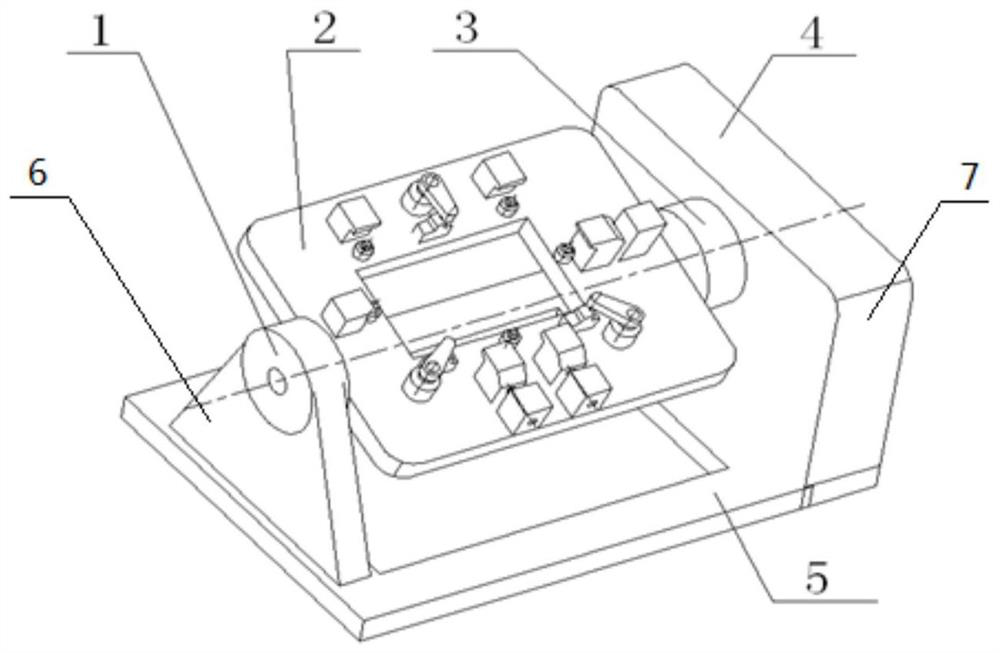

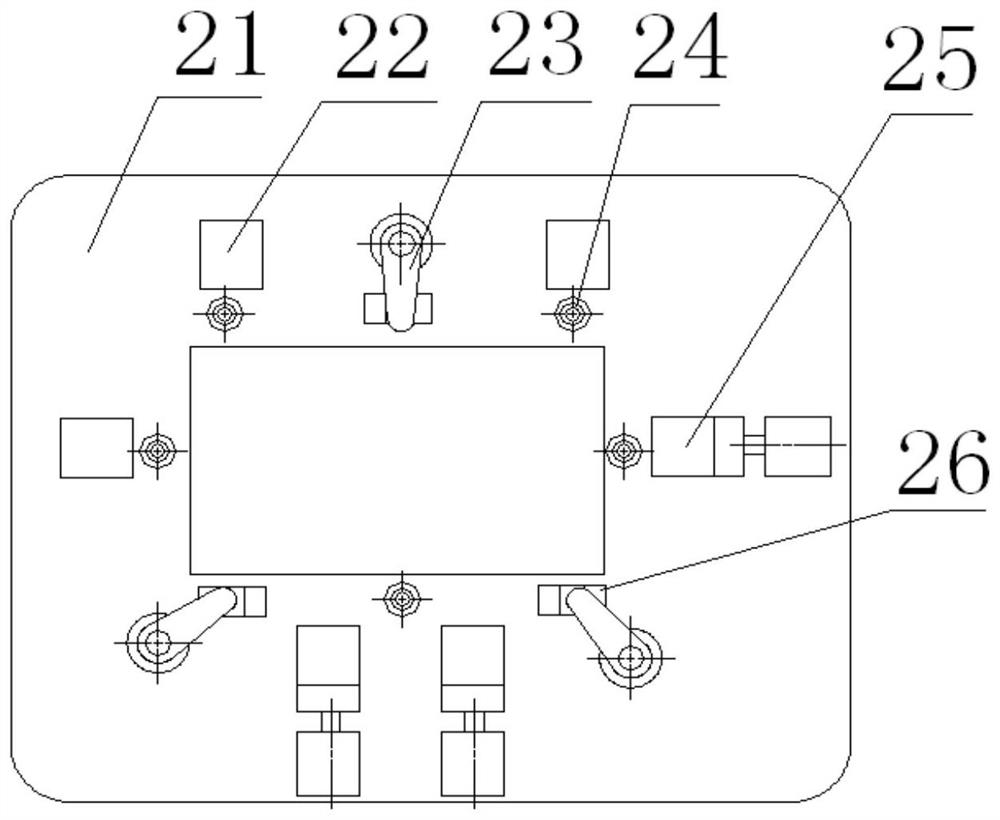

[0050] Such as figure 1 As shown, the tooling for positioning and processing thin-walled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com