Method for integrating a light guide in or onto a support structure

A support structure and light guide technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as deterioration of light guide performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the specification, the term "light guide" means to include all transparent structures arranged to guide light from a first position to a second position along a predetermined length. Generally, such light guides have a length greater than the dimension of their cross-section. However, in this specification, structures with a small length, such as windows, are also included in the meaning of the term "light guide".

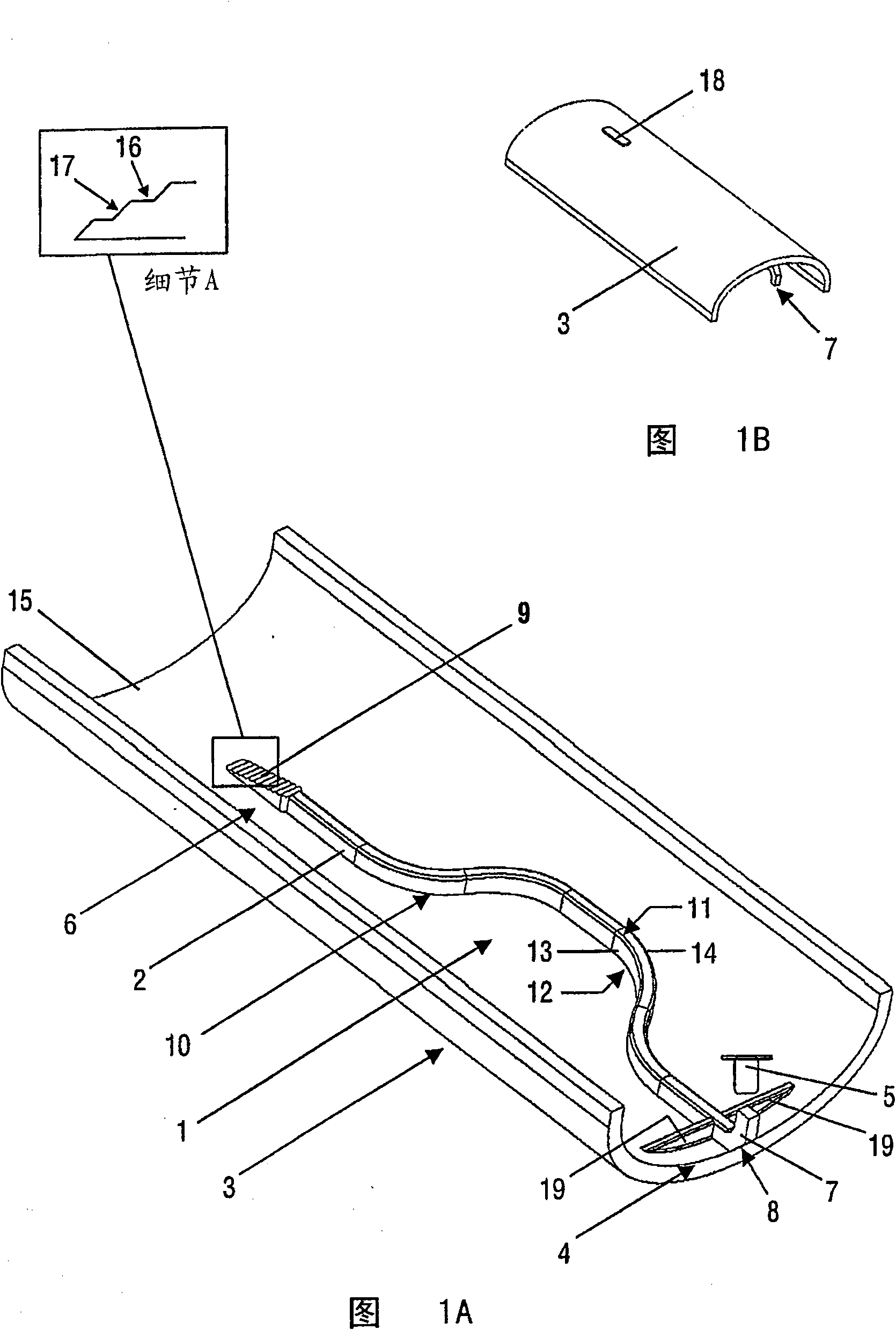

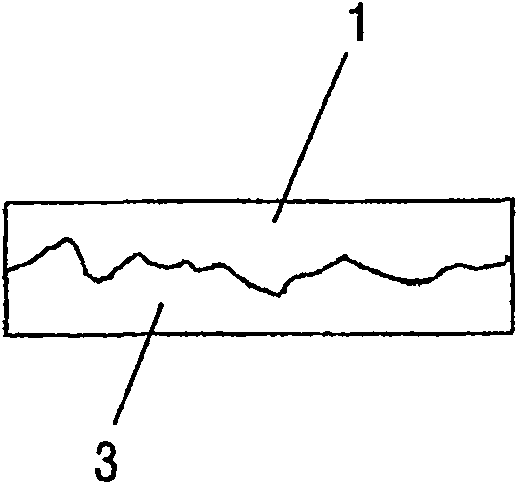

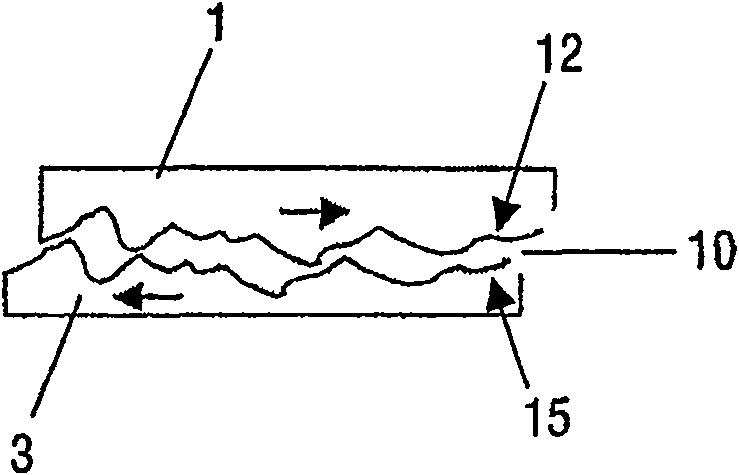

[0029] FIG. 1 shows the light guide 1 extending along the inner side 15 of the support structure 3. The parts 1, 3 are all molded from plastic and separated from each other by a small gap 10 extending between their respective abutting surfaces 12, 15, which is better shown in FIG. 2.

[0030] In the illustrated embodiment, the supporting structure 3 is of a partially cylindrical design, for example, it may form a part of a device or constitute a housing or internal structure of the device, especially an electronic device. Of course, the structure 3 can have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com