Film and method for manufacturing same

a technology of film and film, applied in the field of film, can solve the problems of film deterioration and film is easily peeled off, and achieve the effect of minimizing deterioration and separation of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

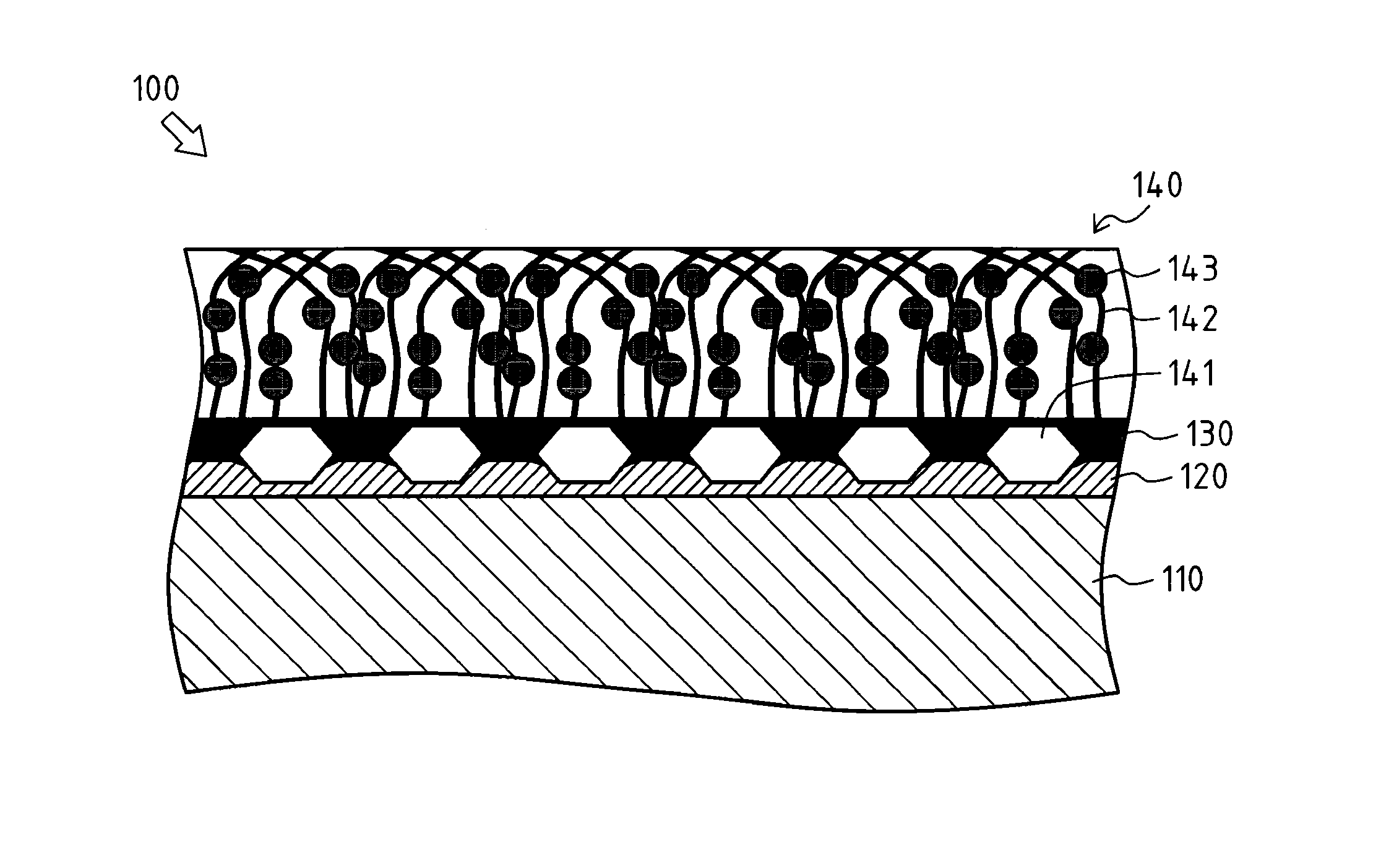

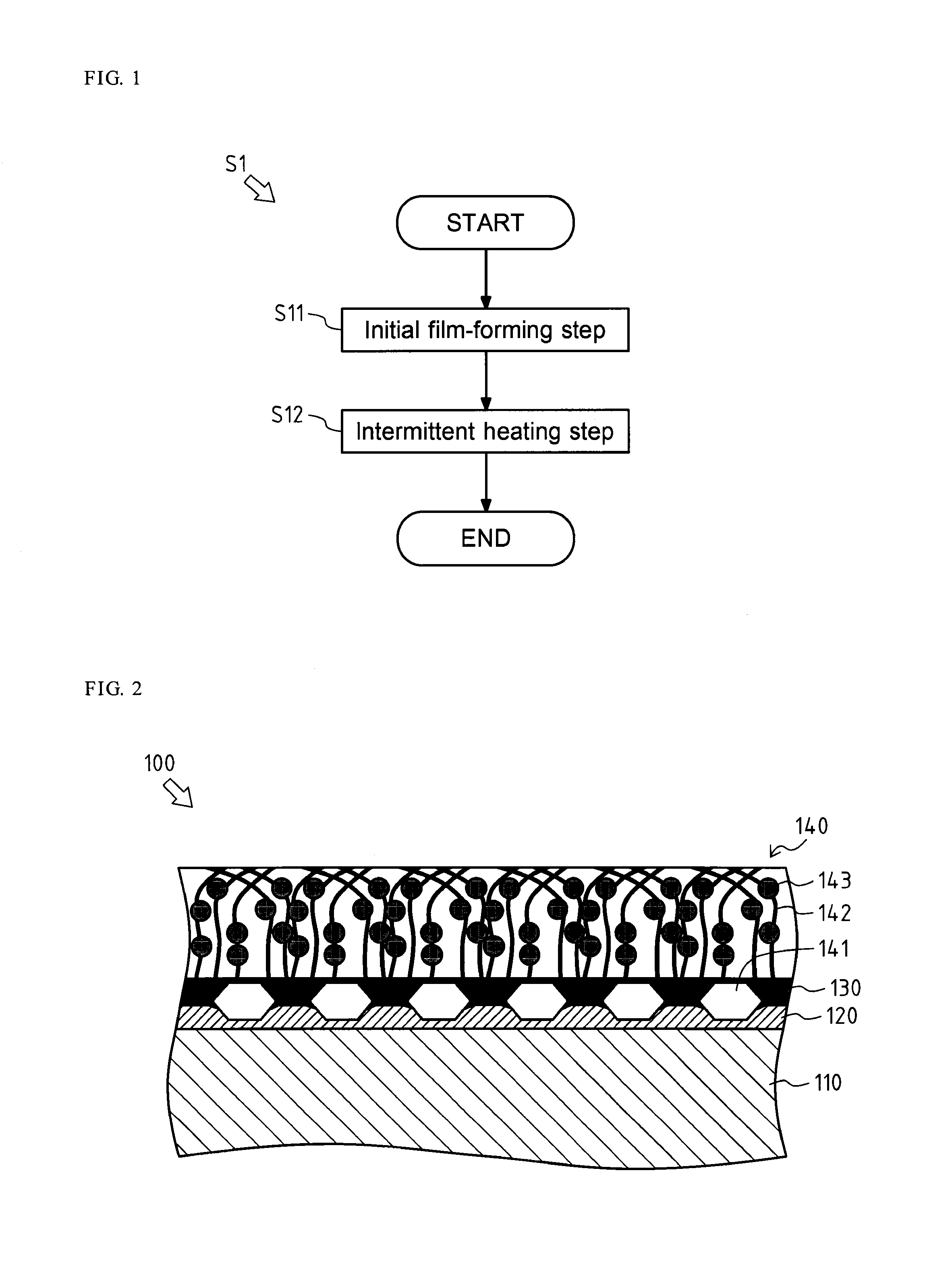

Image

Examples

example

[0082]First, the oil-based release agent was applied to the molding surface of the die on which the initial film 100 was formed, and thereby the initial film 100 was under the non-oxidizing atmosphere.

[0083]Next, the cavity of the die was filled with molten aluminum alloy of 600° C., and the initial film 100 was heated for 5 seconds at 4000 kcal / m2 on the heat-transfer interface (the molding surface of the die) with heat-transfer coefficient of 6000 W / m2K (600° C., 50 MPa).

[0084]Finally, the solidified metal (cast metal) was released from the die.

[0085]By performing the above-mentioned process 1000 times, the film 1 was produced.

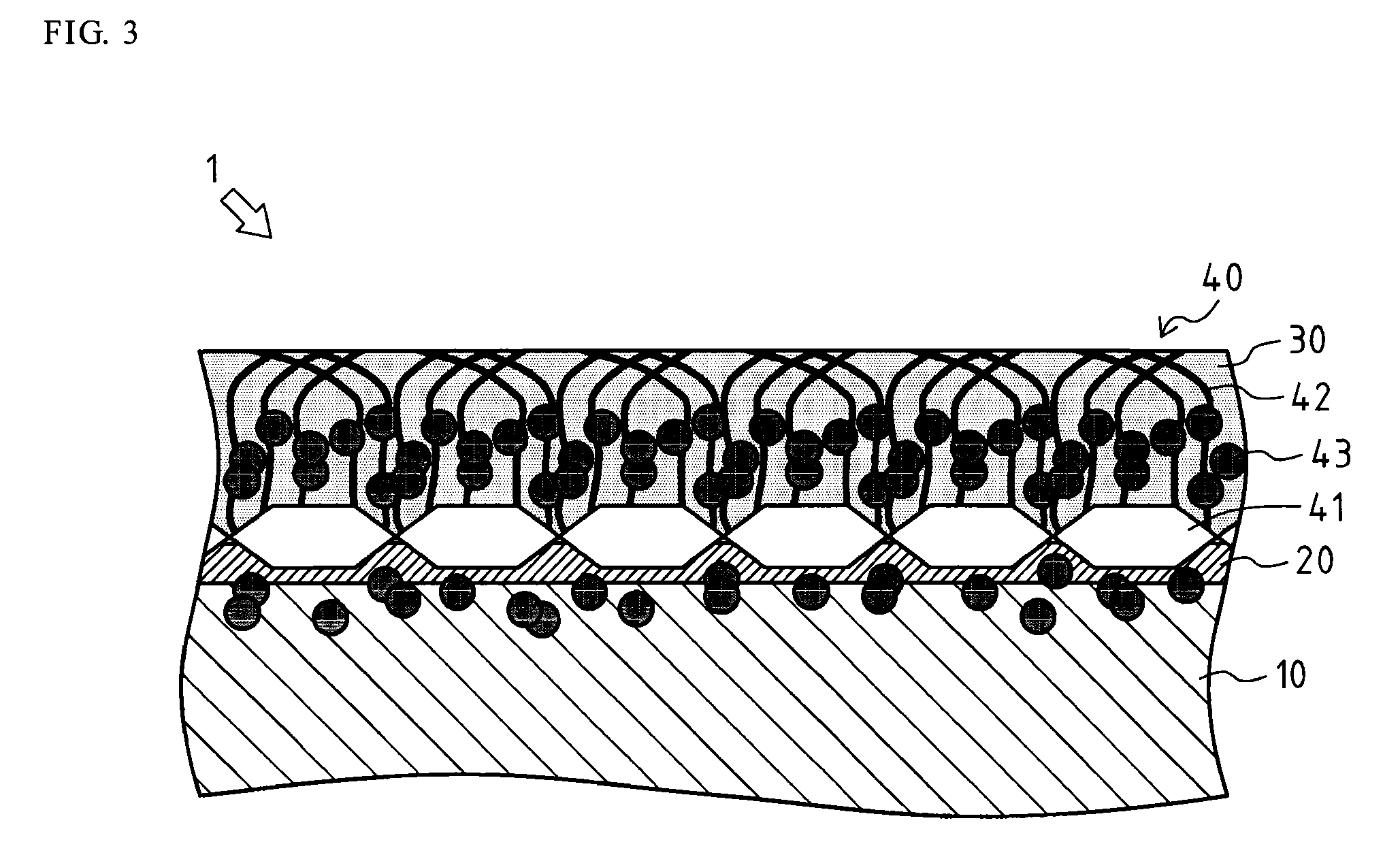

[0086]Mapping analysis of the film 1 was performed using the EPMA, similarly to the initial film 100.

[0087]FIG. 5 shows a result of the mapping analysis of the film 1 with the EPMA. FIG. 5(a) shows carbon present in the film 1, and FIG. 5(b) shows sulfur present in the film 1.

[0088]As shown in FIGS. 5(a) and 5(b), in the carbon film 40 of the film 1, sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com