Papermaking conveyer felt for shoe press and pressing device of shoe-pressing type papermaking machine equipped with the same

A shoe press and paper conveying technology, applied in papermaking, paper machines, textiles and papermaking, etc., can solve the problem that the smoothness of the wet paper surface does not make a contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

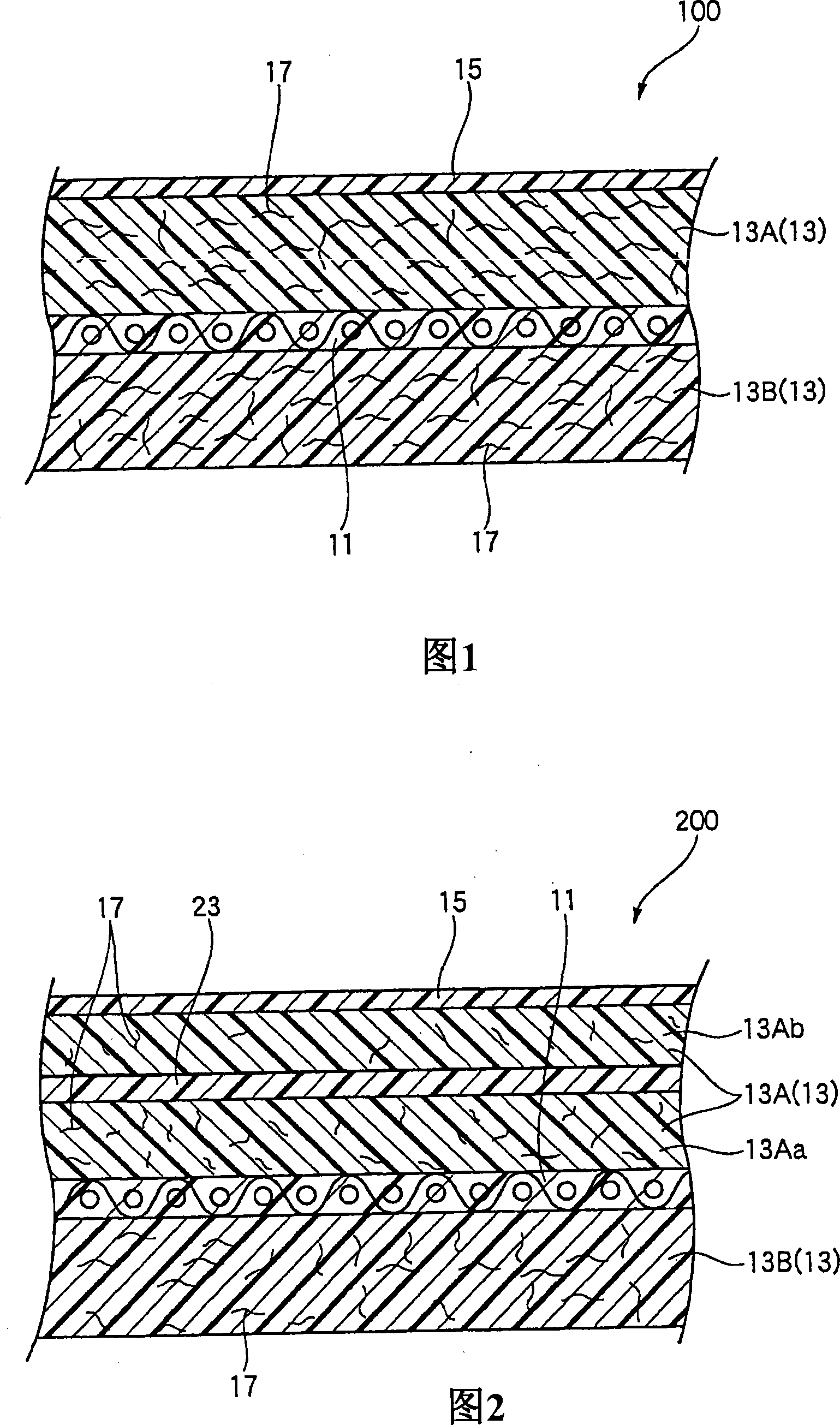

no. 1 example

[0049] As shown in FIG. 1 , the paper transfer felt 100 for a shoe press has a base layer 11 ; a batt layer 13 (a first batt layer 13A and a second batt layer 13B); and a wet paper contact fiber layer 15 . More specifically, the first batt layer 13A is formed on the wet paper side surface of the base layer 11, and the second batt layer 13B is formed on the roll side surface or the shoe side surface of the base layer 11, and the wet paper contacts The fiber layer 15 is formed on the wet paper side surface of this first batt layer 13A so as to be in direct contact with the wet paper. The base layer 11, the batt layer 13 (the first batt layer 13A and the second batt layer 13B), and the wet paper contact fiber layer 15 are wound and bonded by needling.

[0050] The base layer 11 is used to create strength for the paper transport felt 100 for the shoe press, and may suitably be made of, for example, a woven fabric, or a fabric formed of overlapping yarns which have not been woven, ...

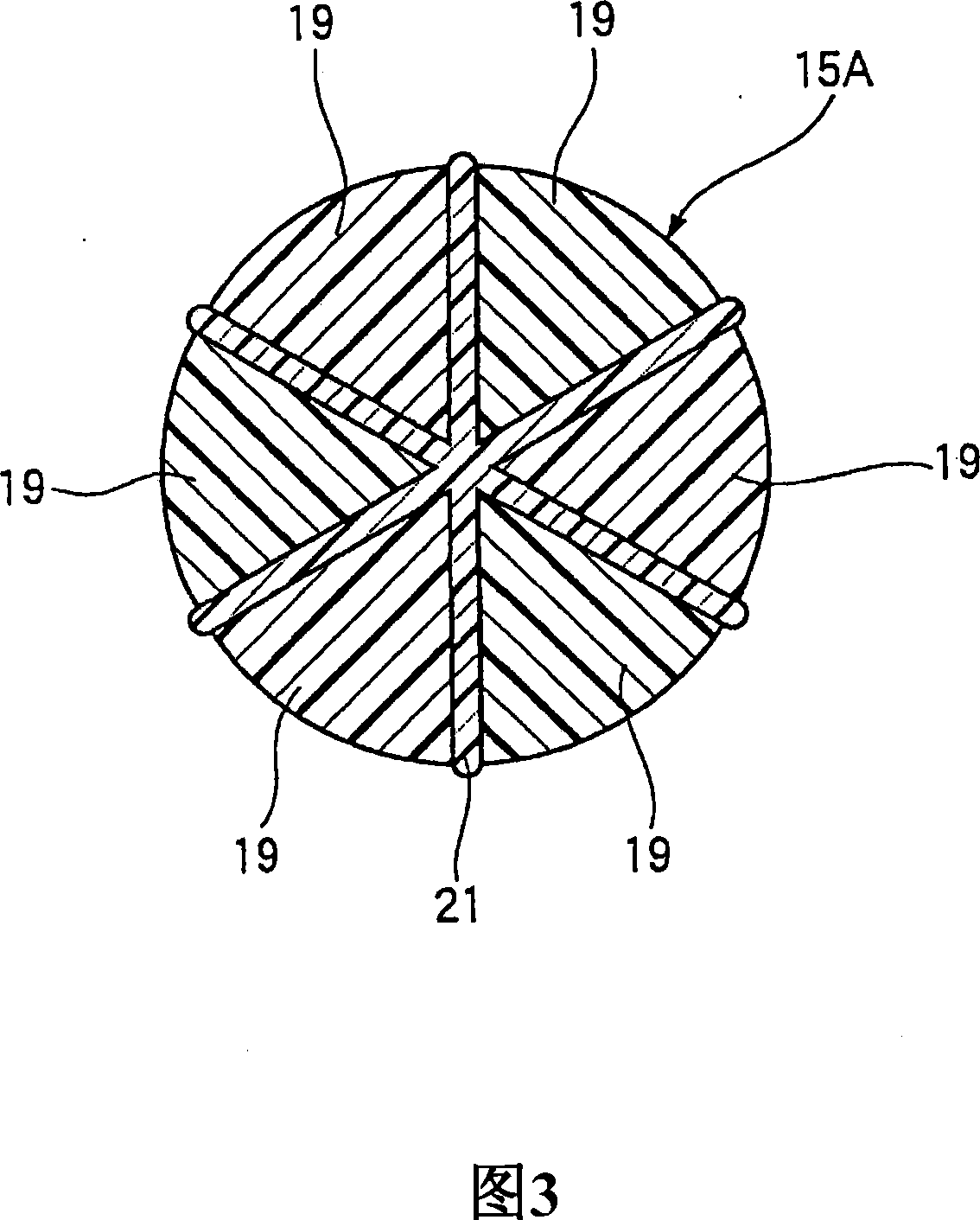

no. 2 example

[0061] A paper transfer felt 200 for a shoe press according to a second embodiment of the present invention will be described below with reference to FIG. 2 . It should be noted that constituent elements similar to those already described in the first embodiment (ie, the paper conveying felt 100 for a shoe press) will be denoted by the same or corresponding reference numerals in the drawings, and descriptions thereof will be omitted or simplified.

[0062] As shown in FIG. 2, in the same manner as the paper conveying felt 100 for a shoe press described above, a paper conveying felt 200 for a shoe press has a base layer 11; Two batt layer 13B); and the wet paper contact fiber layer 15; but the difference from the paper conveying felt 100 for a shoe press is only that this paper conveying felt 200 also has the function of being positioned on the first batt layer in such a manner. Hydrophilic nonwoven fiber 23 in 13A: the first batt layer is located between the base layer 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com