Two adjustment supporting roll device

A technology of adjusting device and backup roller, applied in the field of leveling machine, can solve the problems of poor leveling steel plate precision and uneven wear, etc., and achieve the effect of improving the level of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

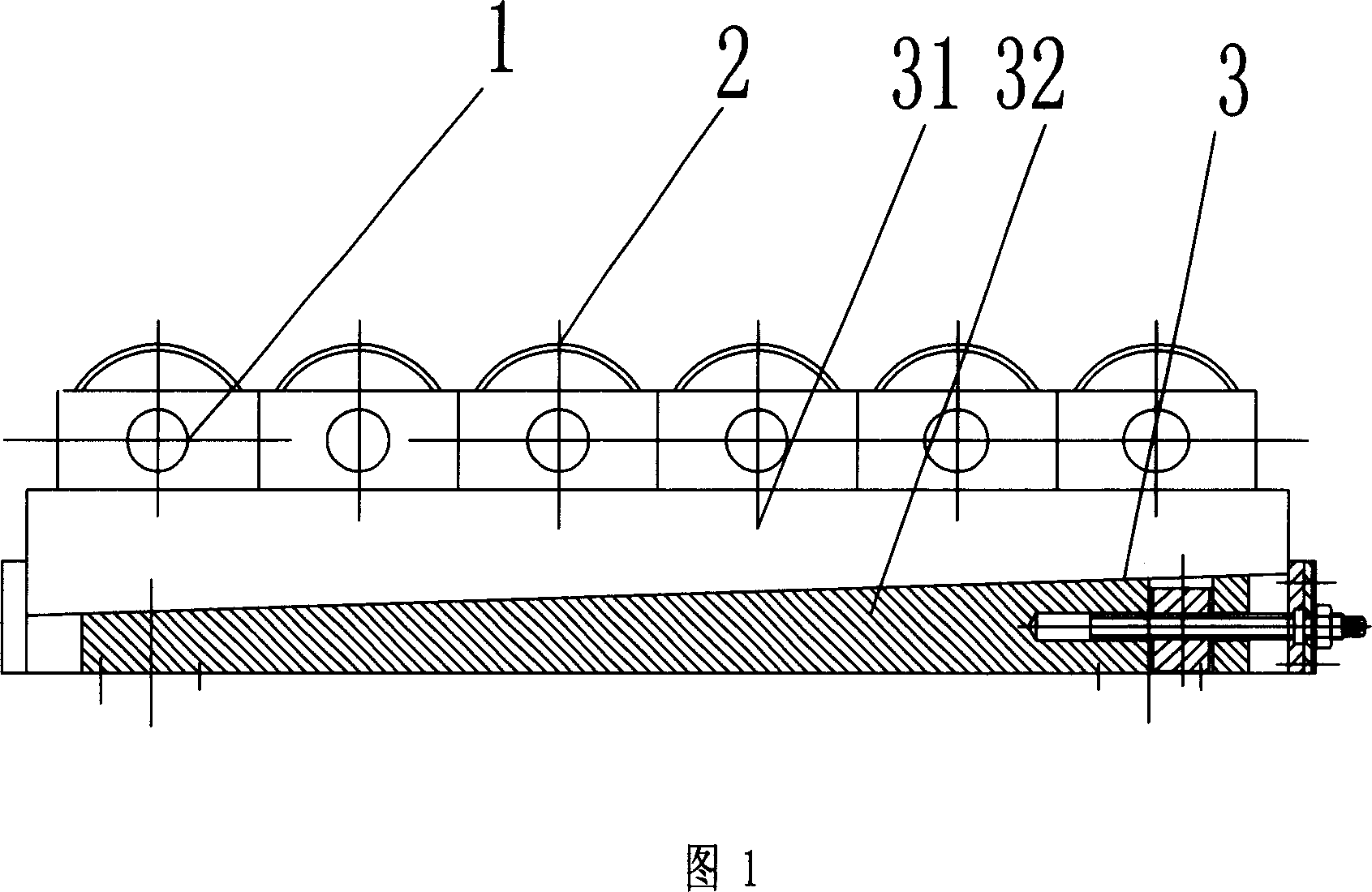

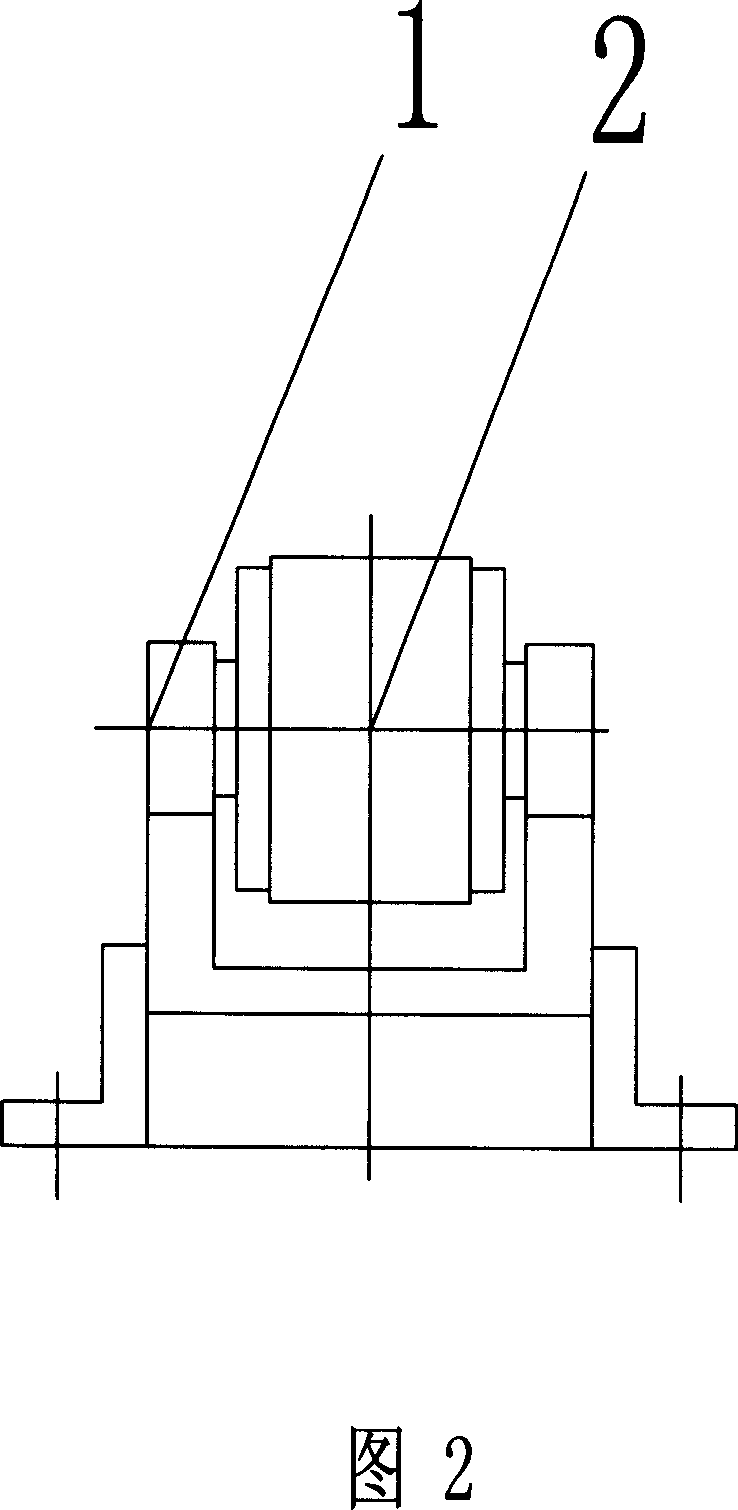

[0009] The present invention will be further described below in conjunction with the accompanying drawings. As shown in Fig. 1 and Fig. 2, the present invention discloses a dual-adjustment backup roller device, which includes a backup roller mounting seat 1, a backup roller 2, and a tilt iron adjustment device 3. The tilt iron adjustment device is divided into an upper tilt Iron 31 and lower slanting iron 32, a single support roller installation seat 1 is arranged side by side on the upper slanting iron 31. 2. A double-adjustable support roller device as claimed in claim 1, characterized in that: The upper inclined iron is provided with an installation groove or a seam matched with the support roller installation seat. In this way, the supporting roller mounting seat and the inclined iron are separated into individual parts and then assembled, which overcomes the disadvantage that the existing supporting roller mounting seat and the inclined iron are integrated and cannot be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com