Helmholtz resonance acoustic board

A technology of resonant sound absorption and resonant body, which is applied in the direction of building components, sound insulation, covering/lining, etc., and can solve the problems of narrow resonance absorption frequency range and reduced sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described and explained in further detail in conjunction with the embodiments and the accompanying drawings.

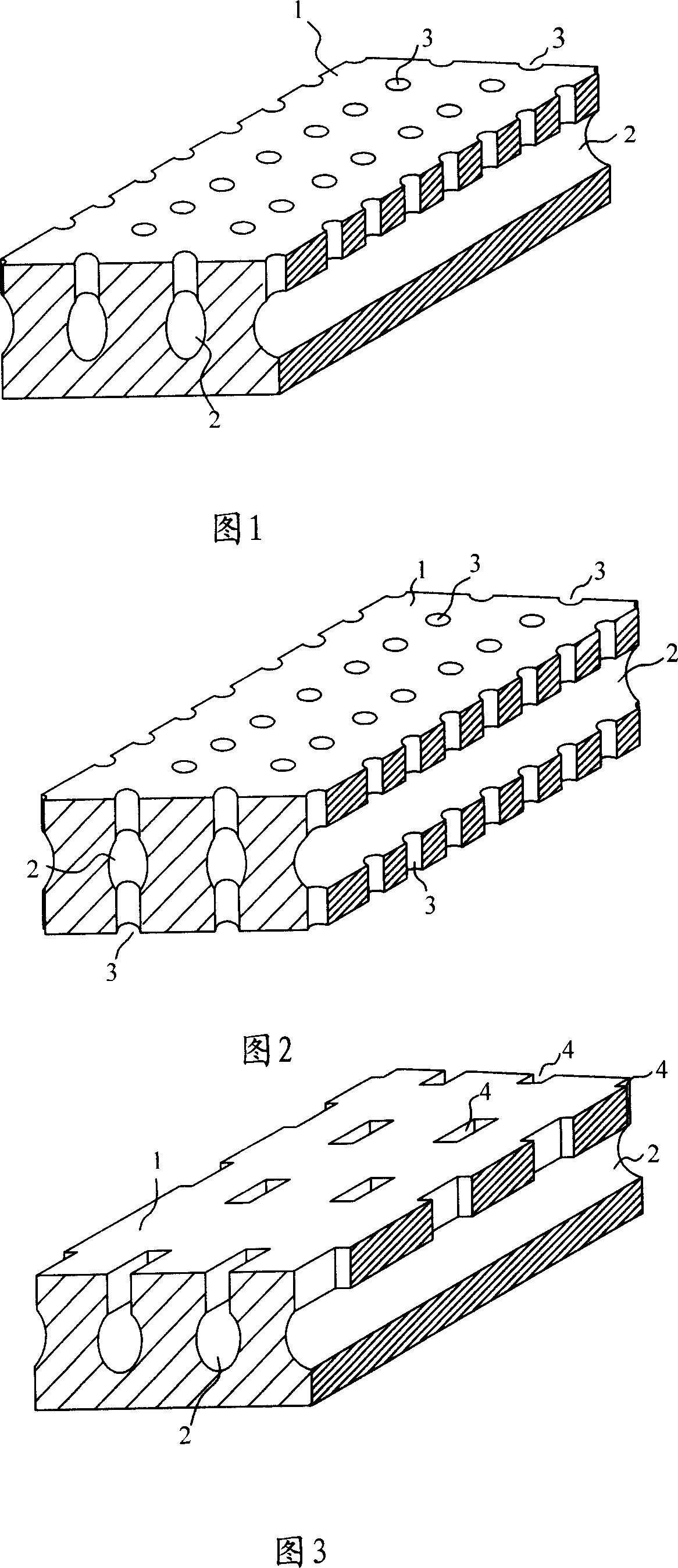

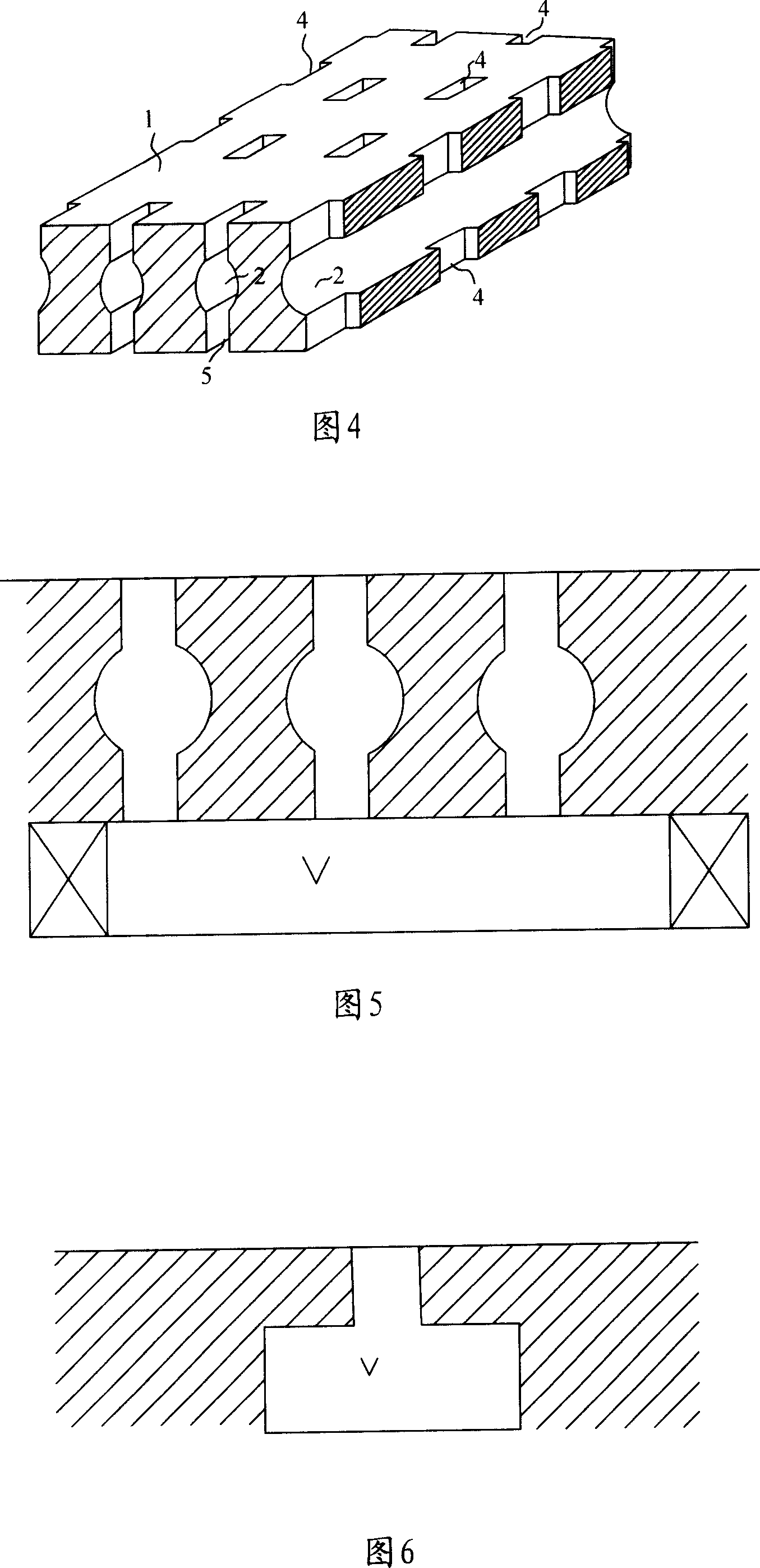

[0015] Referring to FIG. 1 , the first embodiment of the present invention provides a Helmholtz resonance sound-absorbing panel, which includes a rectangular parallelepiped substrate 1, which is a particle board, and has circular through holes running through the front and rear in the lateral direction of the substrate. 2. A circular drill hole 3 is spaced on the upper part of the substrate surface, and is arranged in a row along the axis direction of the through hole. The drill hole 3 is vertically connected to one side of the through hole 2, forming a parallel Helmholtz. Resonator. Since holes with different apertures can be used for the holes 3 on the same substrate, noises of sound waves of different frequencies can be absorbed, so as to achieve a better sound absorption effect. At the same time, the way that circular thro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap