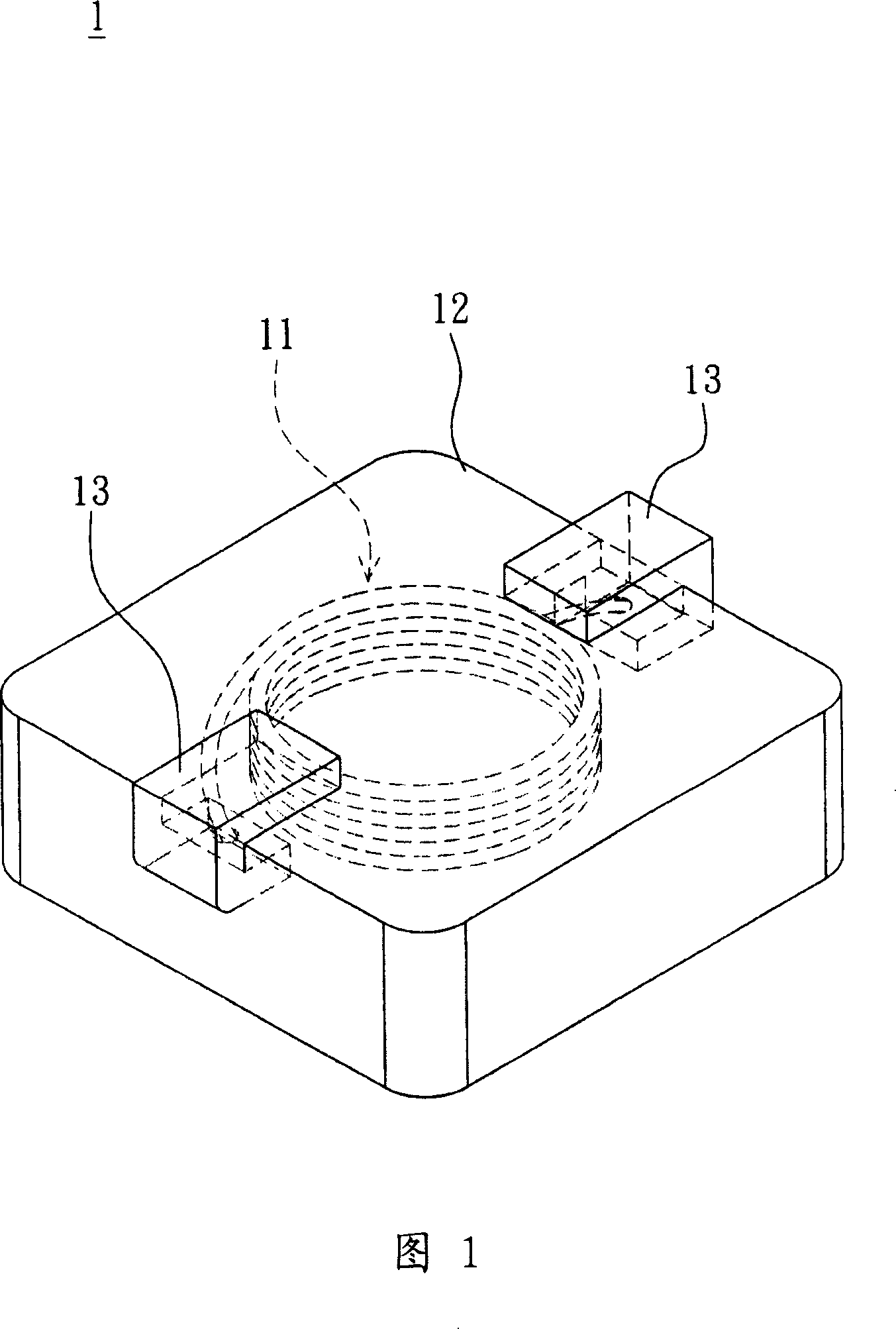

Internal embedded type inductive structure and its producing method

A manufacturing method and embedded technology, which are applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., can solve the problem that the size of the coil 11 cannot be effectively reduced, the thickness of the embedded inductor structure 1 is too large, and it cannot conform to the components. Miniaturization and other issues, to achieve the effect of improving current load characteristics, high inductance value, and high current load tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embedded inductor structure and its manufacturing method according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

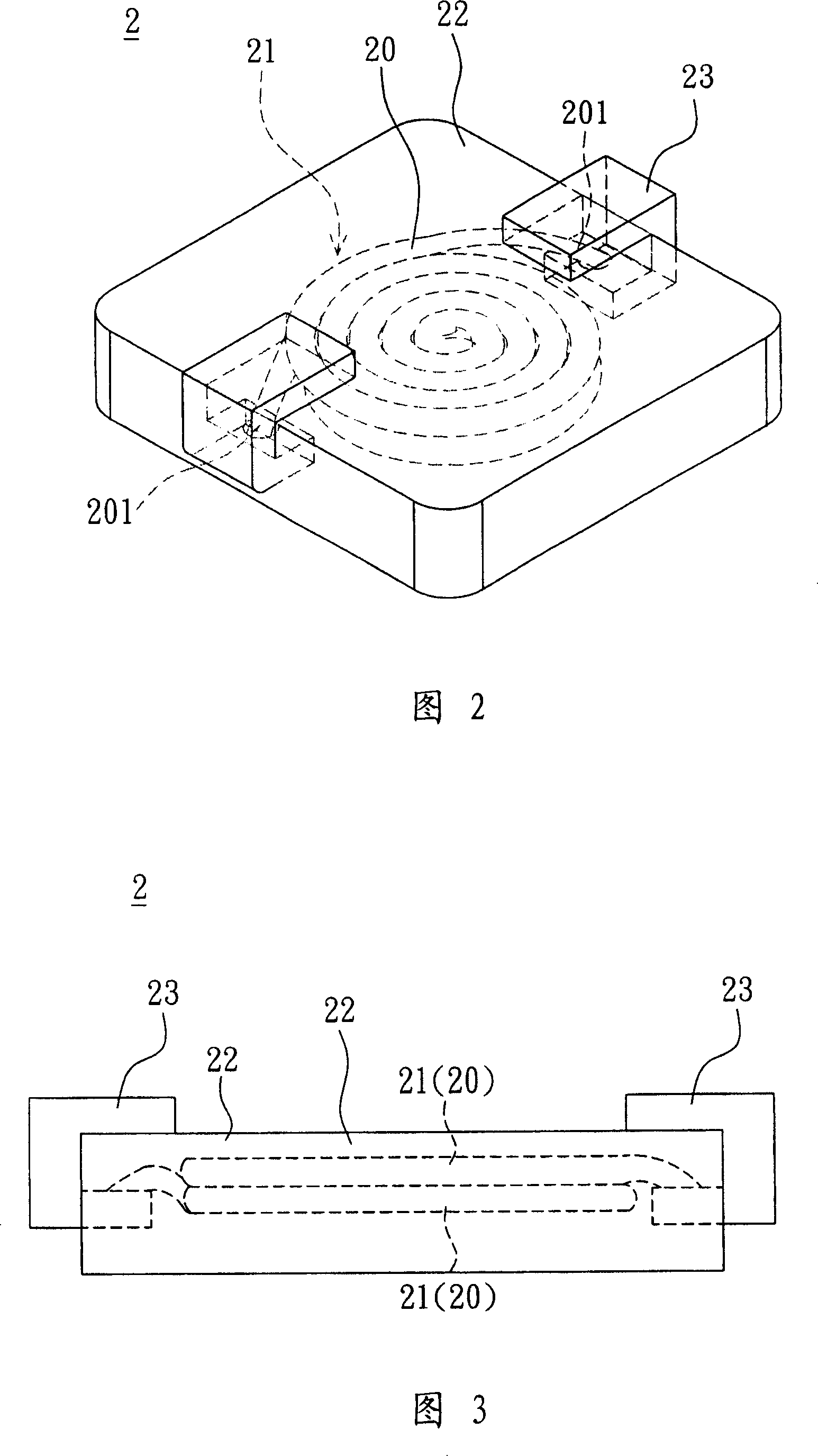

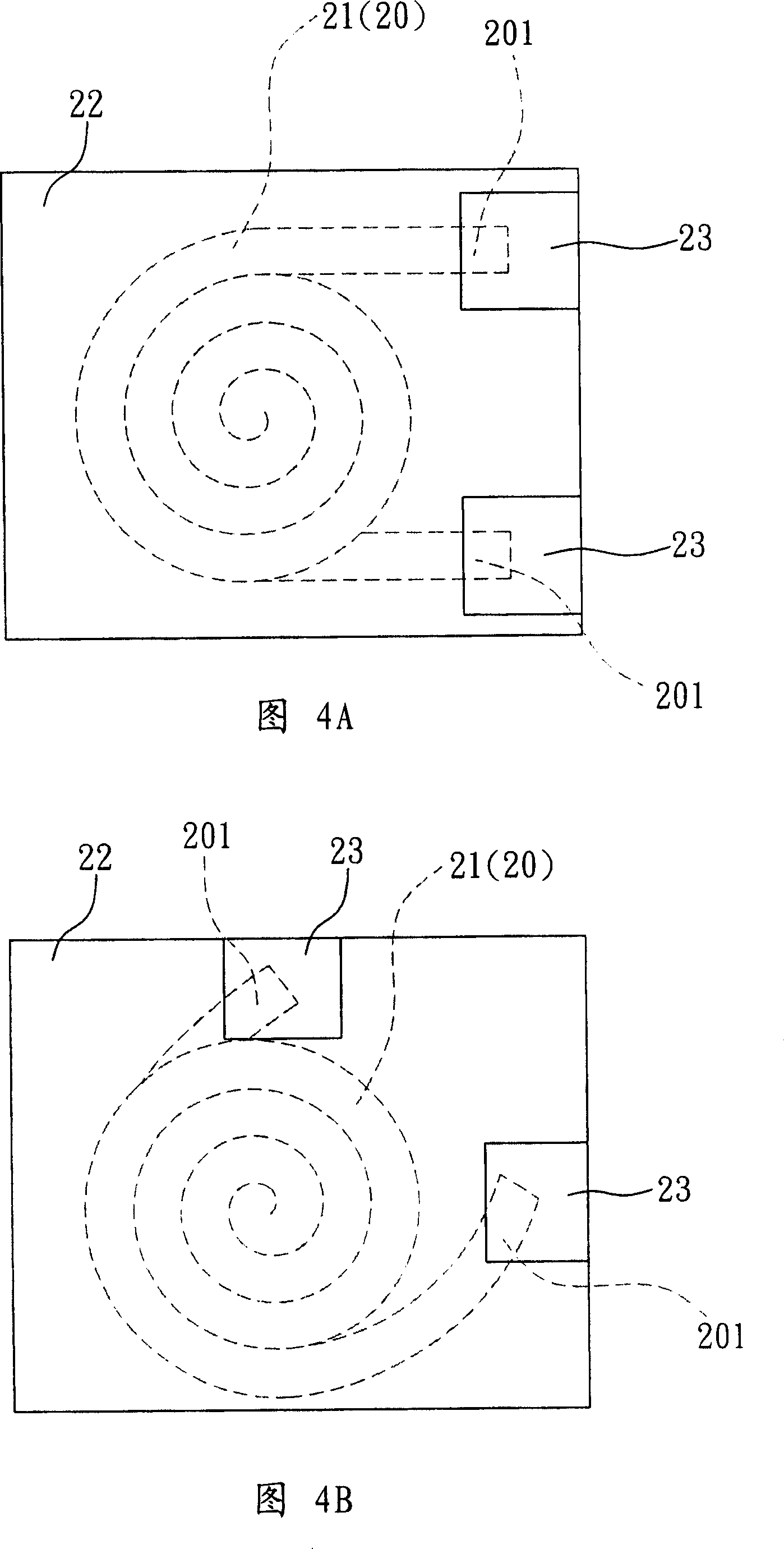

[0027] Please refer to FIG. 2 and FIG. 3 , which are a perspective view and a side view of an embedded inductor structure 2 according to a preferred embodiment of the present invention. The embedded inductor structure 2 includes at least one coil 21 , a magnetic body 22 and two terminals 23 .

[0028] The coil 21 is formed by winding a conductive wire 20 from the middle section to the two ends 201 in a spiral manner, so that the coil 21 is tightly arranged in a spiral shape, so that more coils can be wound under the same volume condition Number, in order to achieve the effect of increasing the inductance value. Then the ends 201 are respectively connected to the terminals 23, as a structure for electrical connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com