Spindle unit and machining device

A technology for spindles and thrust bearings, which is applied in the direction of drive devices, shafts and bearings, grinding drives, etc., and can solve problems such as thermal deformation of the shell or spindle, inability to rotate the spindle, and narrow gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

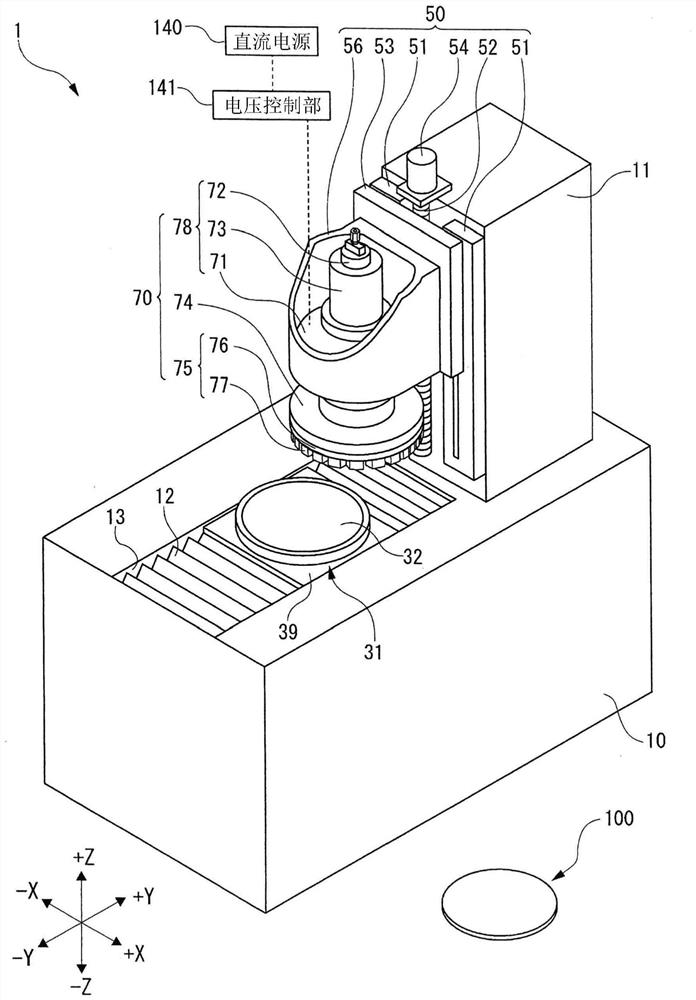

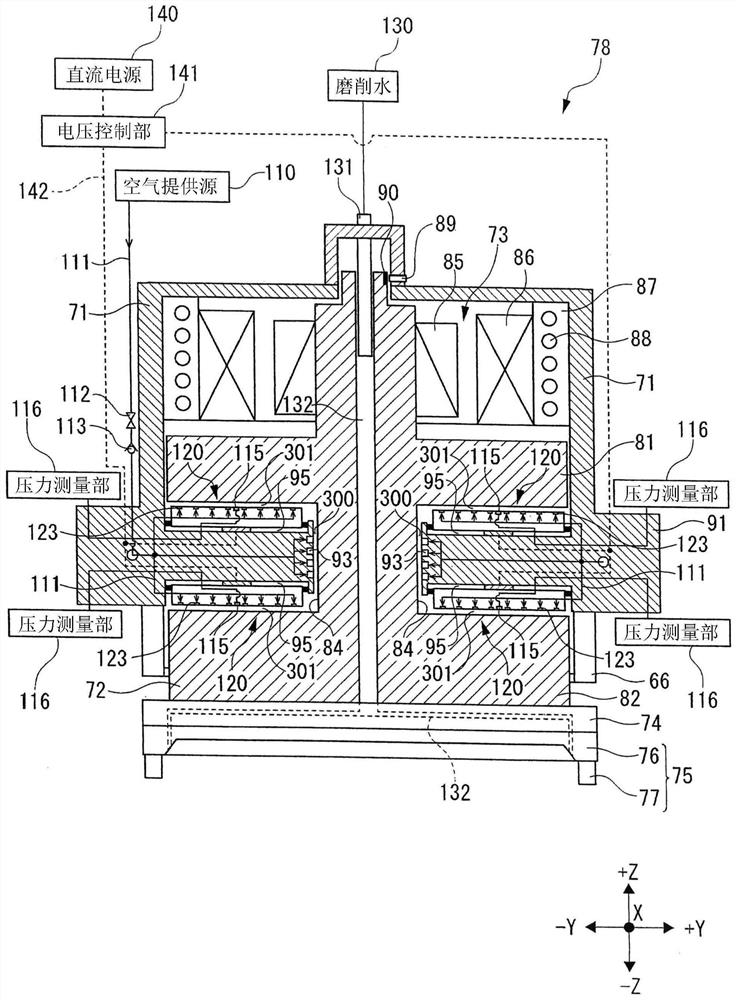

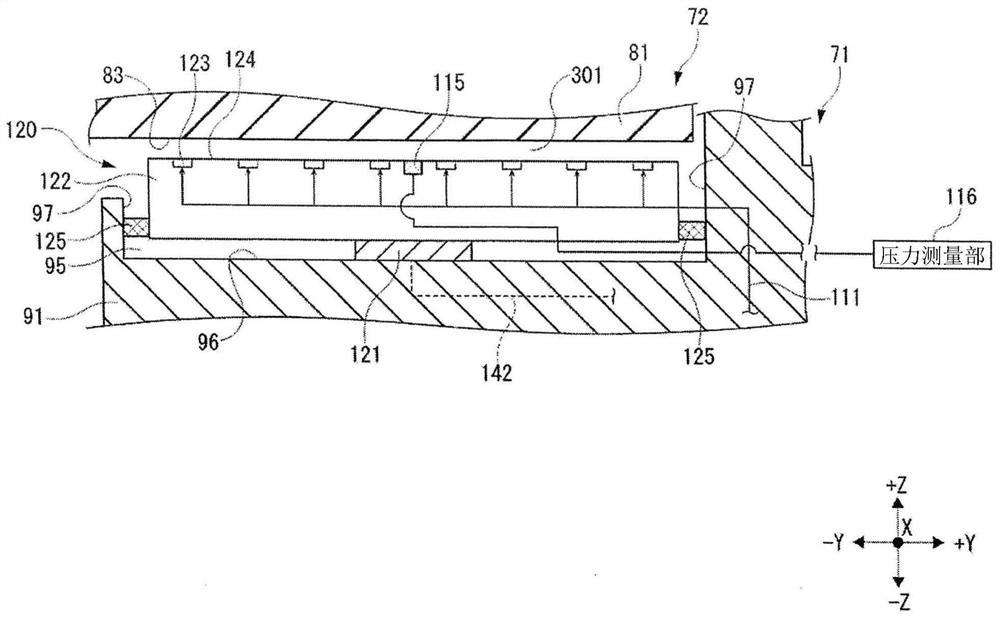

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings. like figure 1 As shown, the grinding apparatus 1 of the present embodiment is an example of a processing apparatus, and is an apparatus for grinding a wafer 100 as a workpiece. The wafer 100 is, for example, a semiconductor wafer.

[0024] The grinding device 1 has a cuboid base 10 and a column 11 extending upward.

[0025] An opening 13 is provided on the upper surface side of the base 10 . In addition, a chuck table 31 as a holding unit is arranged in the opening 13 . The chuck table 31 has a holding surface 32 for holding the wafer 100 .

[0026] The holding surface 32 of the chuck table 31 is made of a porous material, and communicates with a suction source (not shown), whereby the wafer 100 is sucked and held. That is, the chuck table 31 holds the wafer 100 via the holding surface 32 .

[0027] In addition, the chuck table 31 can hold the wafer 100 by the holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com