Optoelectronic device, element driving device and electronic equipment

A technology of electro-optical devices and electro-optical components, which is applied in the field of component drive devices and component substrates, and can solve problems such as crystal defects, pixel circuit difficulties, and disordered characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. The following forms are only one form of the present invention, and do not limit the present invention, and can be changed arbitrarily within the scope of the present invention. In addition, in each of the drawings shown below, the size and ratio of each component are appropriately different from the actual size and ratio in order to make each component a recognizable size on the drawing.

[0124]

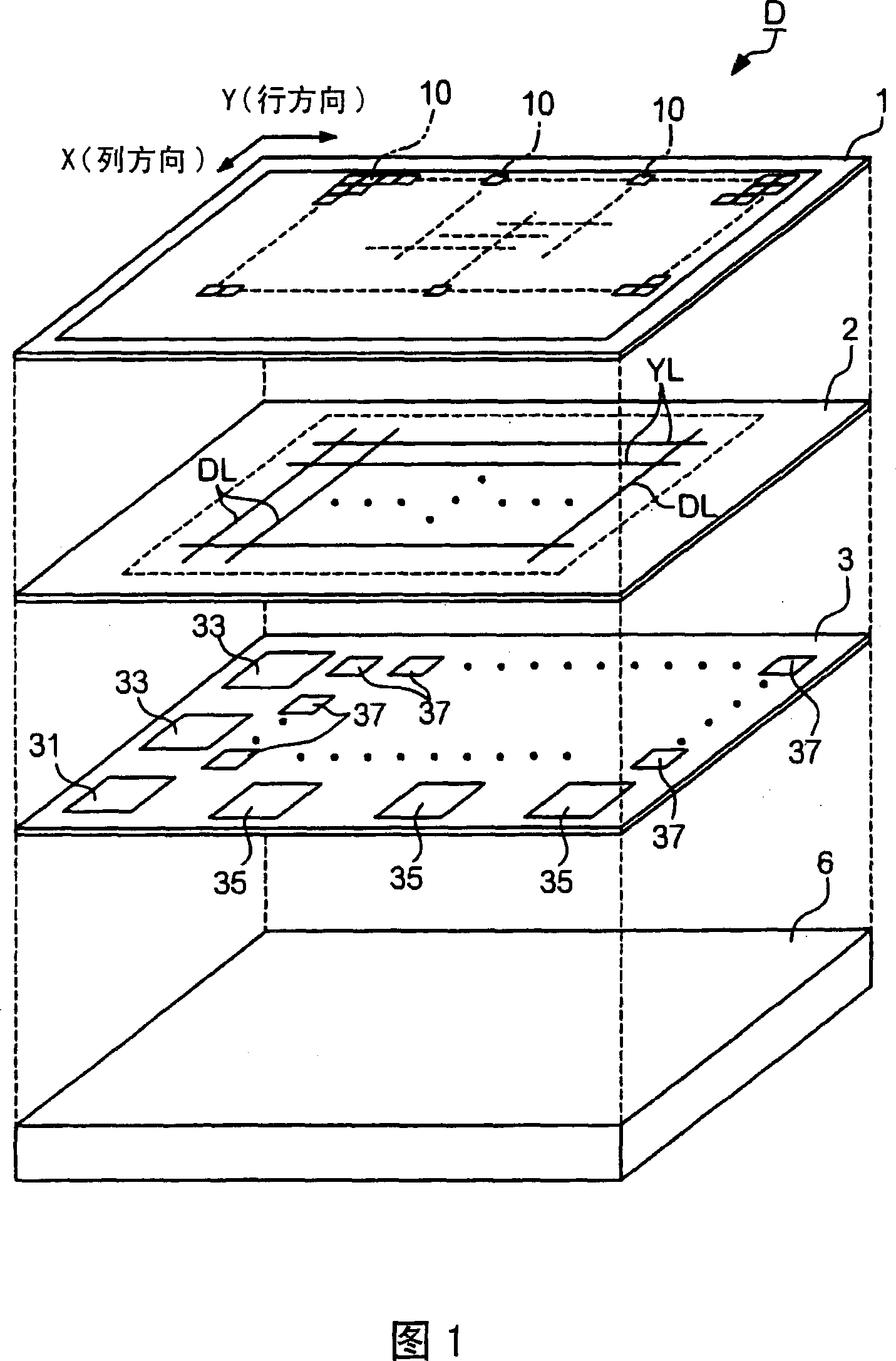

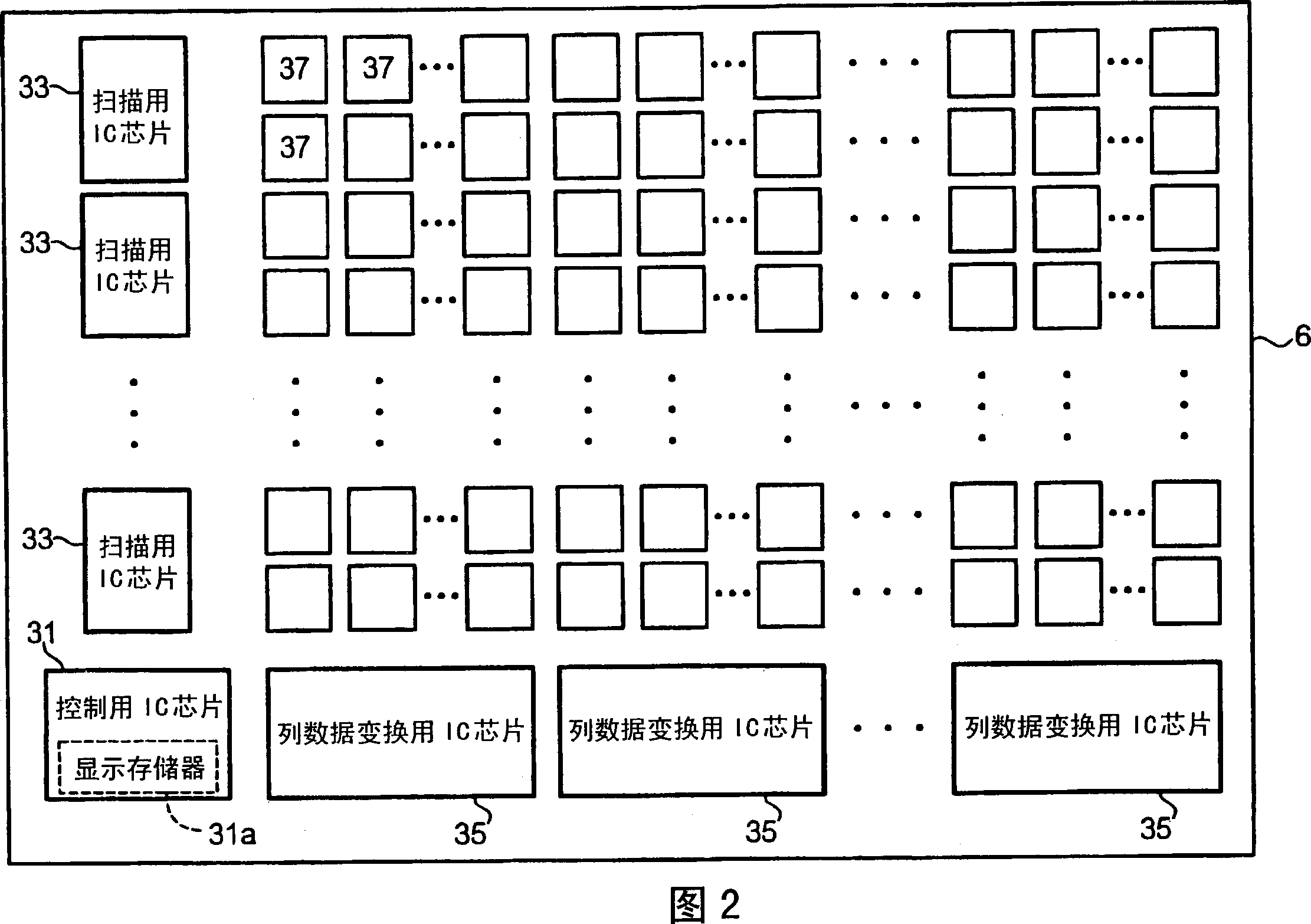

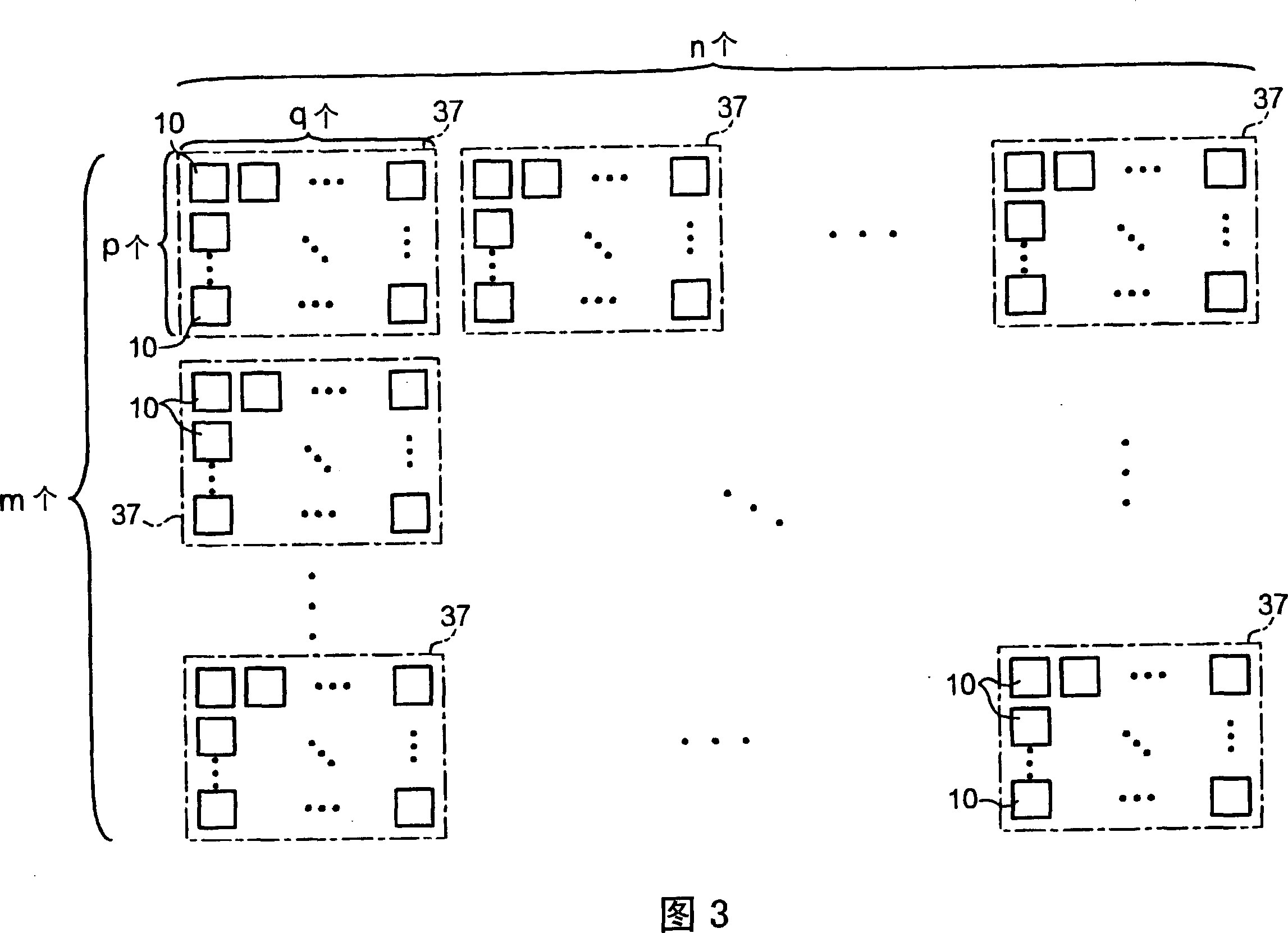

[0125] First, as a device for displaying an image, an embodiment applicable to the electro-optical device of the present invention will be described. FIG. 1 is a perspective view showing the structure of an electro-optical device according to an embodiment of the present invention. As shown in the figure, the electro-optical device D has a support substrate 6 , an organic EL layer 1 , a wiring formation layer 2 , and an electronic component layer 3 . The support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com