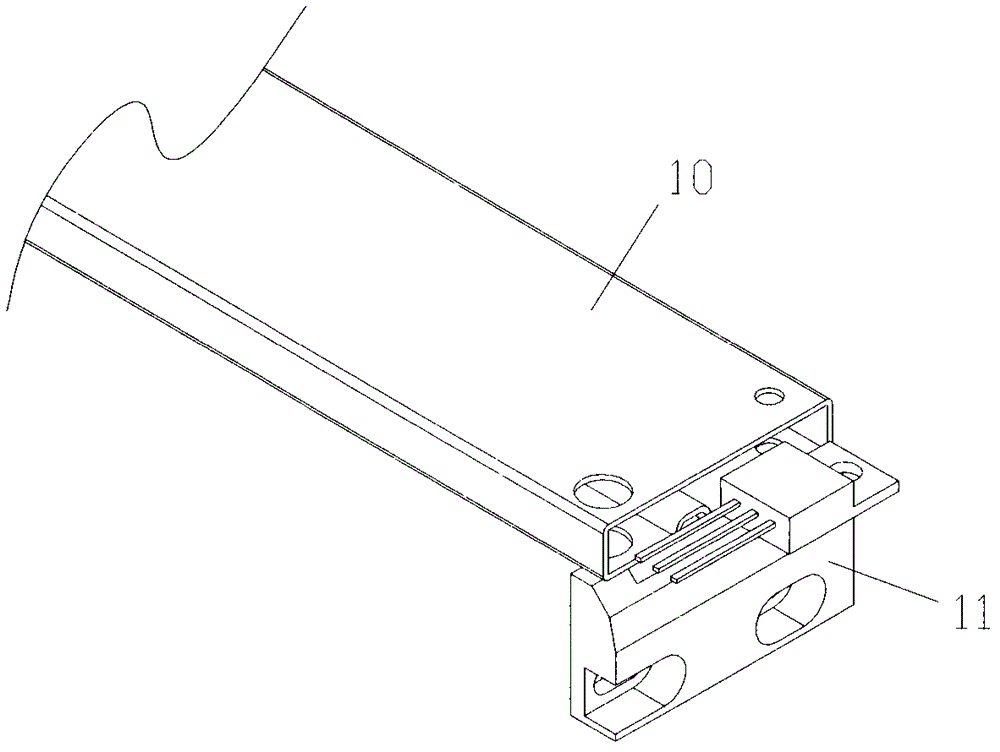

Tube pulling mechanism for test sorting machine

A technology for testing sorting machines and drawing tubes, applied in packaging and other directions, can solve the problems that triodes cannot be arranged in an orderly manner, affect production, and are easy to move, and achieve the effects of convenient implementation, high practicability, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

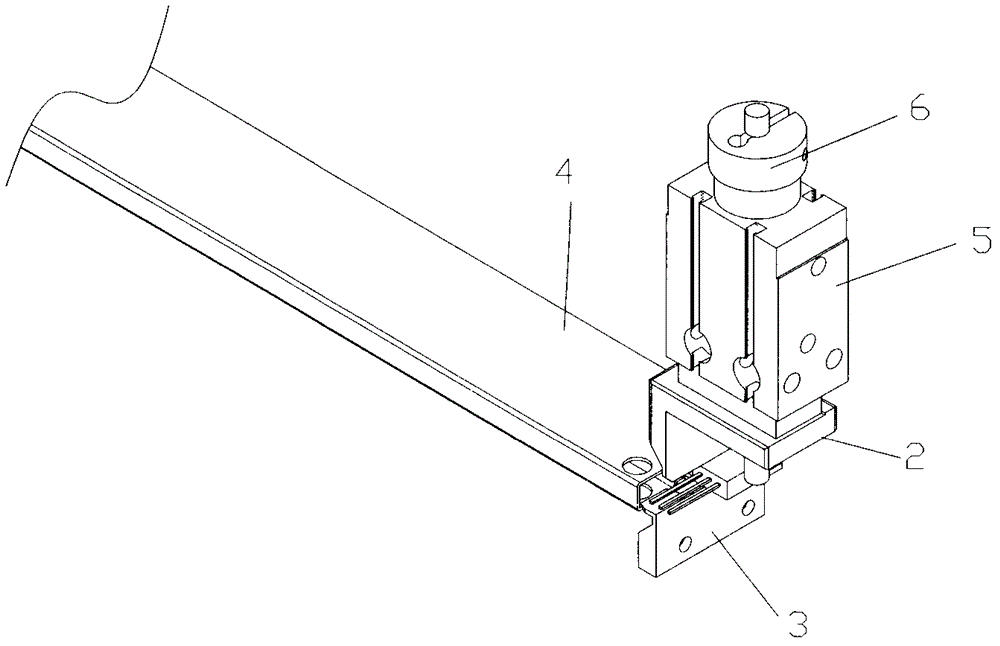

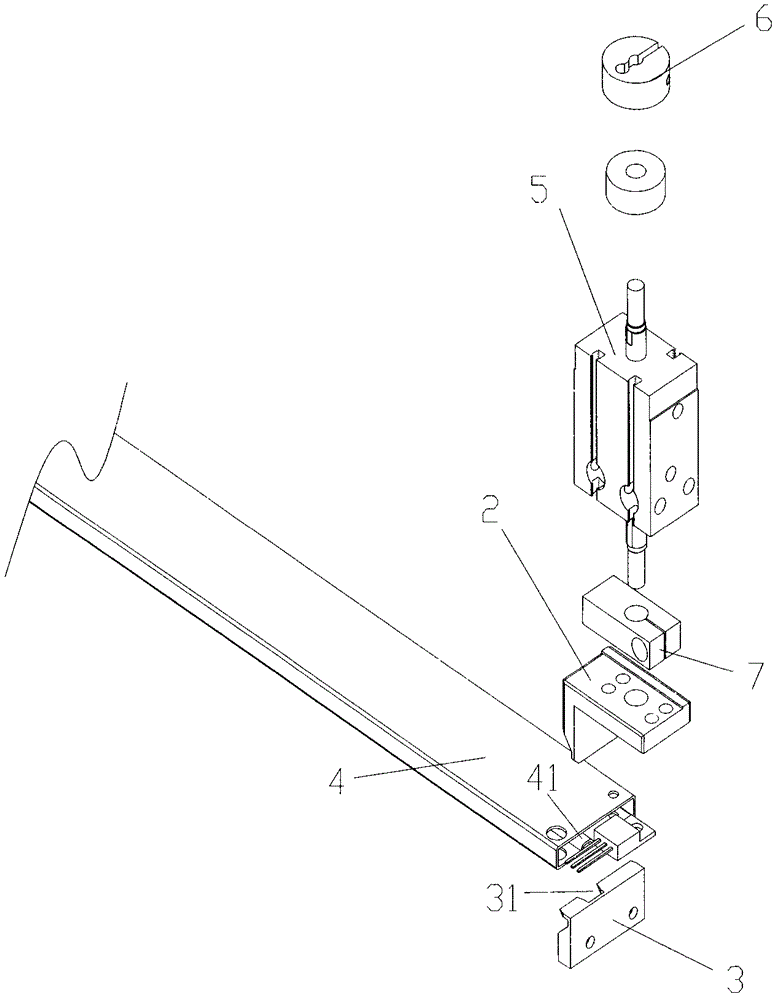

[0015] The present invention is further described below in conjunction with accompanying drawing:

[0016] refer to figure 2 , 3 As shown, it is a schematic structural diagram of a preferred embodiment of the present invention; the present invention relates to a tube-drawing mechanism for a test sorter, which has at least a pair of upper and lower tube hooks 2,3, and an upper and lower tube hook 2,3 Correspondingly pull the opposite sides of the input port of the triode tube bar 4 to expand the input port of the triode tube bar. During work, the hook heads of the upper and lower tube hooks 2 and 3 hook the opposite sides of the input port of the triode tube bar 4, and apply an external force that pulls and stretches the input port of the triode tube bar outwards, so that the input port of the triode tube bar The port is slightly opened to ensure that the triode can enter the triode tube smoothly, thereby improving the production efficiency.

[0017] In this embodiment, at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com