Omnidirectional rotary workbench for pole mounted operation

A rotating work, all-round technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to rotate, poor safety in working with insulating ladders, and difficulty in displacement and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

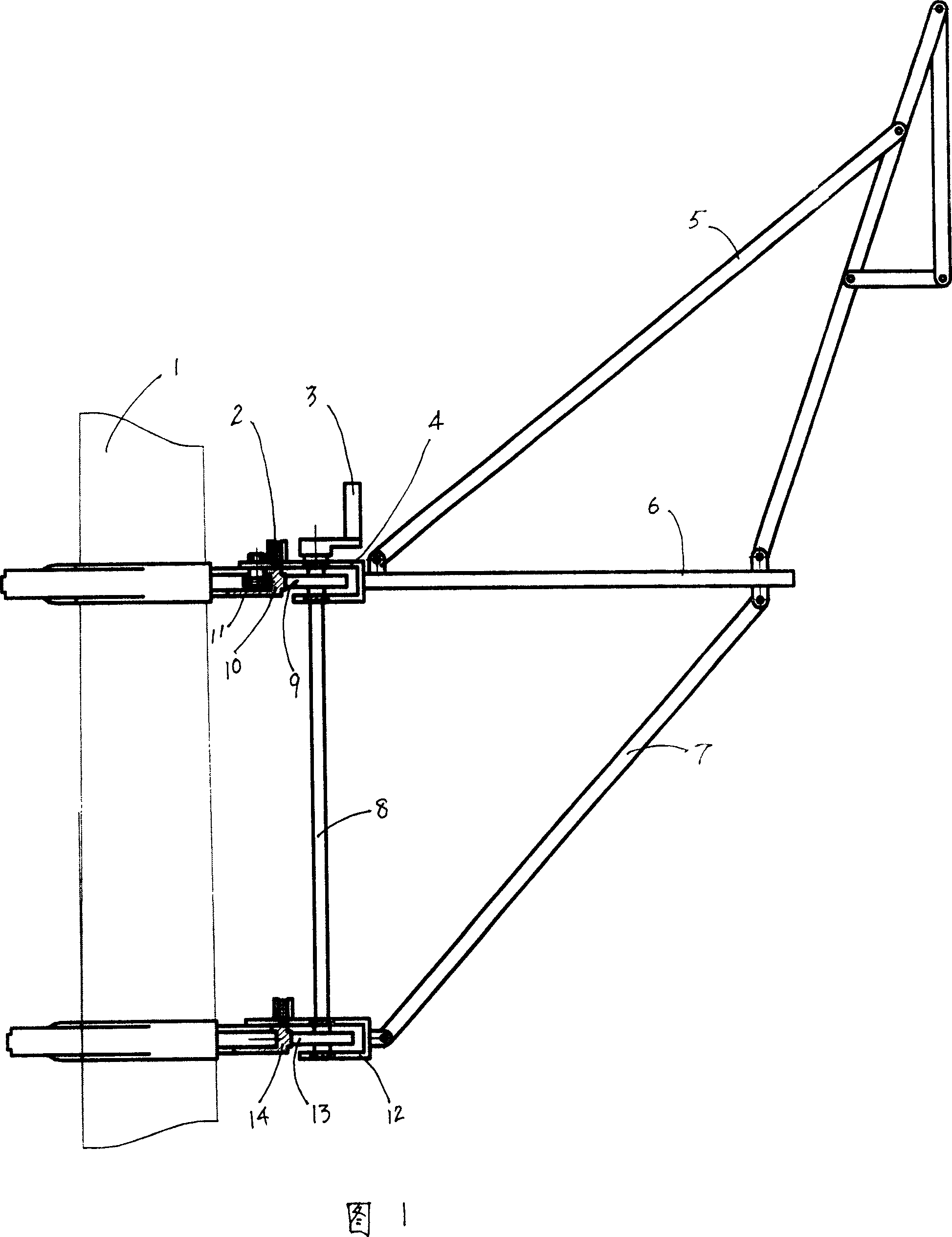

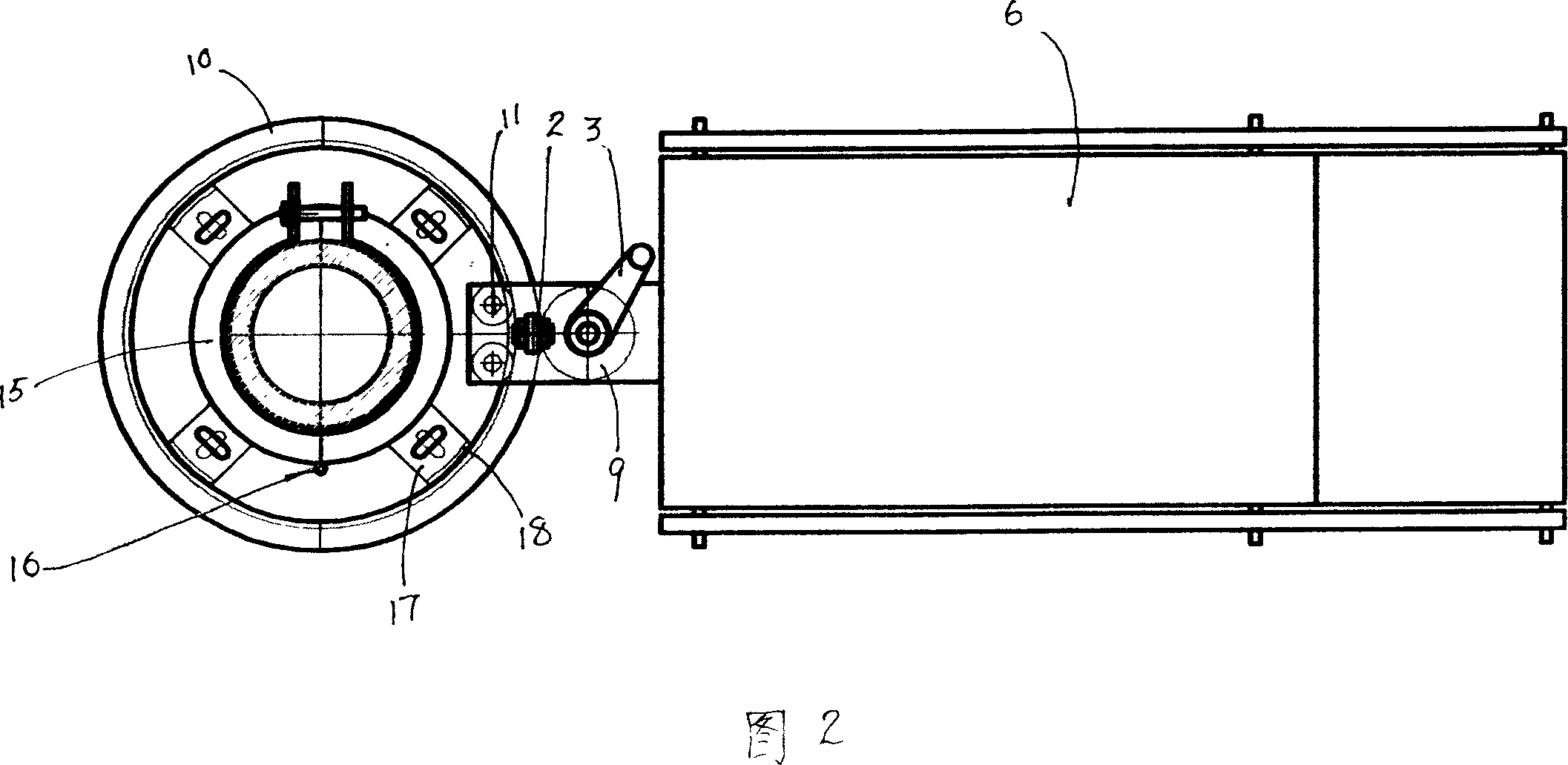

[0011] As shown in Fig. 1-Fig. 2, a kind of omni-directional rotating work platform for working on poles according to the present invention includes upper and lower hoops 15 which can be fixed with cement pole 1, and are socketed and fixed outside the upper hoops. The ring gear 10 that is fastened by the two halves, and the rotating gear 9 matched with the ring gear 10, the rotating gear 9 is installed on the upper connecting plate 4; a rotating ring 14 that is fastened by the two halves is fixed outside the lower hoop, and the rotating ring 14 contacts and connects with a runner 13, and the runner is installed on the lower connecting plate 12; said rotating gear 9 and runner 13 are connected by the same shaft 8, and a rocking handle 3 is installed on the upper end of the shaft; said upper connecting plate 4 Connect the insulating platform 6, on which the guardrail 5 is also installed, and the bracket 7 connected with the lower connecting plate is installed under the insulating...

Embodiment 2

[0016] In Embodiment 1, on the ring gear 10 where the two halves are snapped together, a fixing bolt device can be added on the inner edge of the junction, and Embodiment 1 is repeated for the rest.

[0017] The present invention is not limited to above-mentioned embodiment, as the fixing of ring gear and rotating ring and hoop, can use the wheel spoke that one end is screwed with ring gear or rotating ring, and the other end is screwed with hoop; The number of spokes also can be more than 4 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com