Cyclone separator of vacuum cleaner

A technology of cyclone separator and separator, which is applied in the direction of suction filter, etc., can solve the problems of increasing the height of the isolation ring, increasing the volume and manufacturing cost of the vacuum cleaner, and must be moved down at the same time, so as to improve the versatility, improve the dust collection effect and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

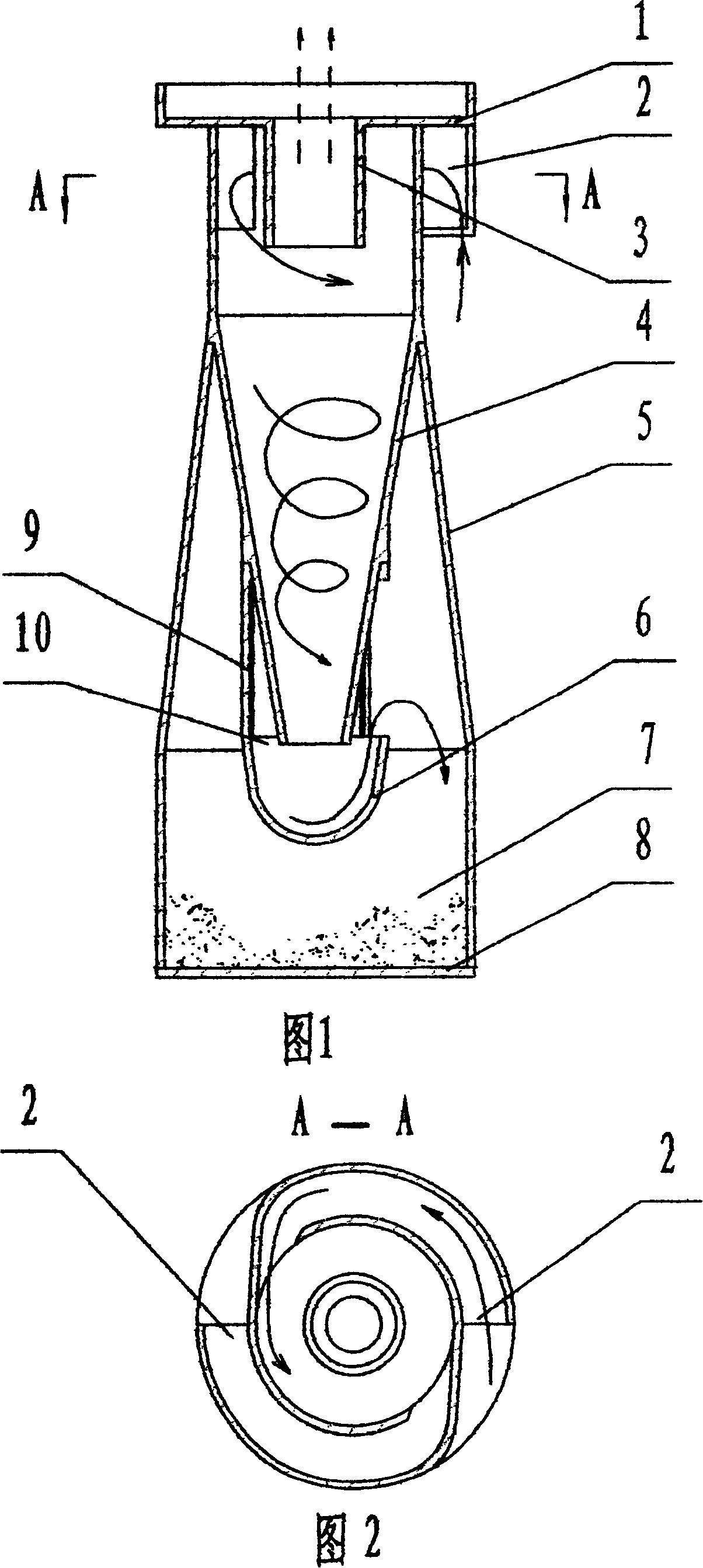

[0019] Fig. 1, Fig. 2 are a kind of embodiment of the present invention. As shown in the figure, the cyclone separator of the vacuum cleaner includes a cylinder body 5 and a tangential air inlet 2 arranged at the upper end of the cylinder body. The top of the cylinder is connected with the bracket 1, and the center of the cylinder is provided with a short air outlet tube 3 with a bottom hole of the bracket, and the inner wall of the cylinder 5 below the position of the short tube is provided with a tapered cylinder 4 with a large top and a small bottom. There is a certain distance for dust collection between the bottom of the cylinder body and the bottom cover 8 to form a dust collection chamber 7, and an isolation pocket 6 is installed at the bottom of the cone-shaped cylinder body, between the inner wall of the isolation pocket and the outer wall of the cone-shaped cylinder. An annular gap 10 is left, and the peripheral wall of the isolation pocket is connected to the outer ...

Embodiment 2

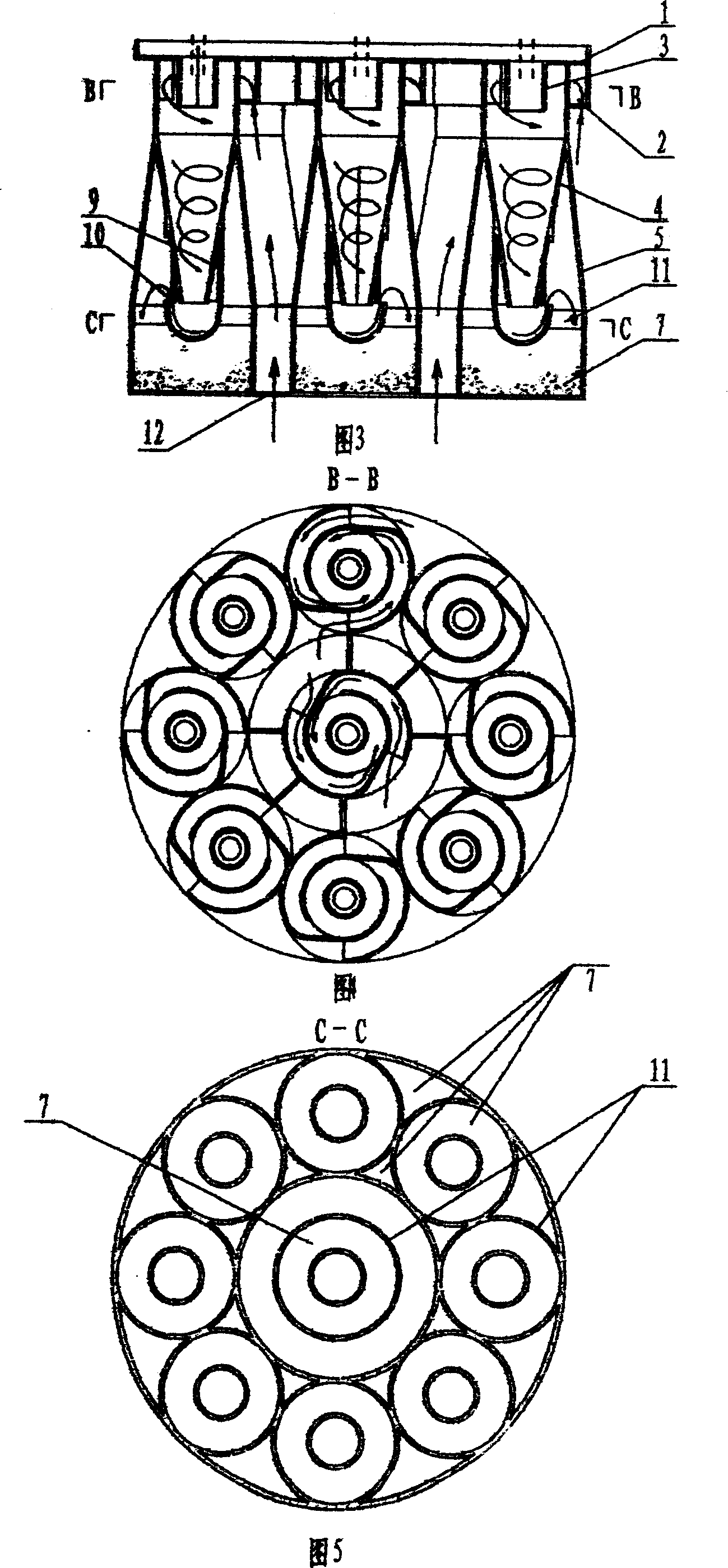

[0022] Fig. 3, Fig. 4, Fig. 5 are another embodiment of the present invention. As shown in the figure, in this embodiment, a plurality of single separators are combined and installed in the dust cup in parallel. A center separator is arranged in the center of the dust cup, and a plurality of outer ring separators are arranged around the center separator, and the bottoms of the outer ring separators communicate with each other to form an annular dust collection chamber 7 . The air outlet short pipe 3 in the center of each separator is respectively connected to the bottom hole of the corresponding support 1, and the adjacent spiral blades at the upper and lower ends of the separator are connected to each other tangentially to the air inlet 2, and the conical blades in the separator cylinder 5 are connected to each other. The lower part of the cylinder 4 is respectively connected to an isolation pocket 6 through radial connecting ribs. There is a distance between the cylindrical ...

Embodiment 3

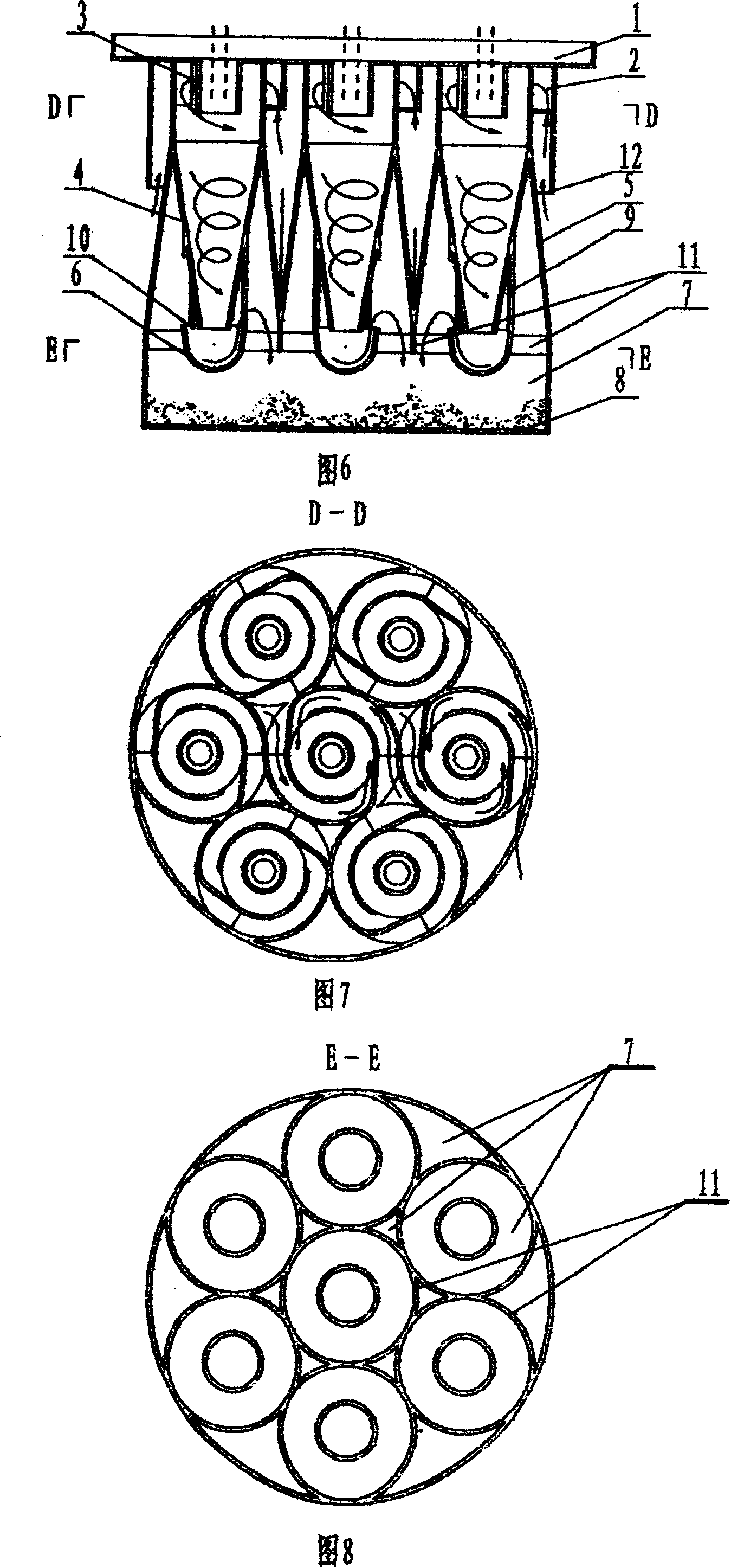

[0025] Fig. 6, Fig. 7, Fig. 8 are another embodiment of the present invention. As shown in the figure, in this embodiment, a plurality of separators are combined in parallel to form a whole and installed in the dust cup. An isolation cover 13 is installed on the periphery of the upper part of the separator. There is a gap between the isolation cover 13 and the peripheral wall of the separator, thereby forming The air inlet 12 of the separator. A center separator is arranged in the center of the dust cup, and a plurality of outer ring separators are arranged around the center separator. The central separator and the outer ring separator share a dust collection chamber. The inner walls at the bottom of the conical part of each cylinder body 5 of the separator are connected to each other. Each separator cylinder extends to the dust collecting chamber to form the isolation ring 11. The lower edge of the isolation ring is slightly lower than the upper edge of the isolation pocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com