Multi-inflow drainage hopper

A drainage box and inlet technology, applied in the field of multi-inflow synthetic resin drainage box bucket, can solve problems such as interruption of work, achieve the effect of reducing connecting parts, easy cleaning or inspection, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

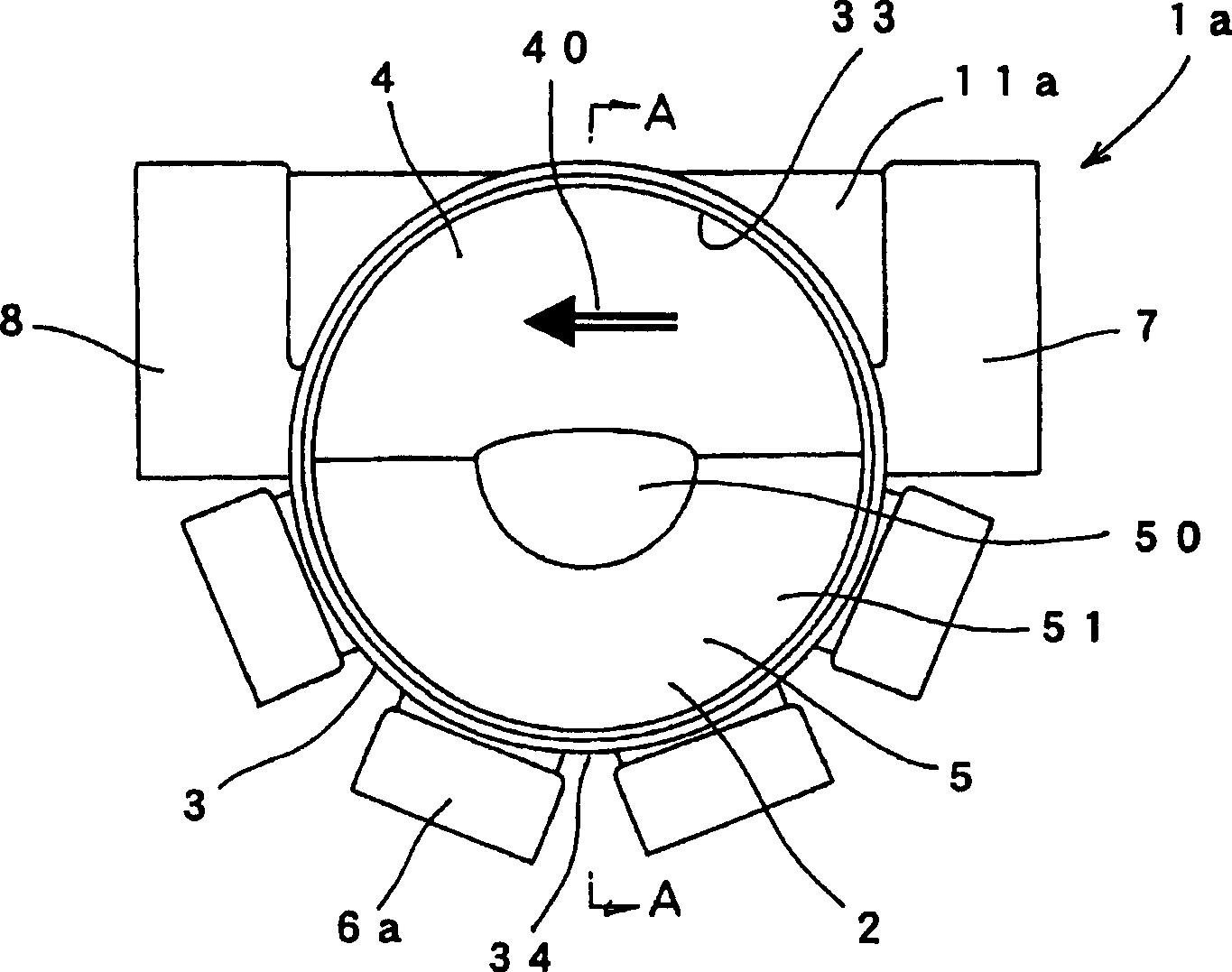

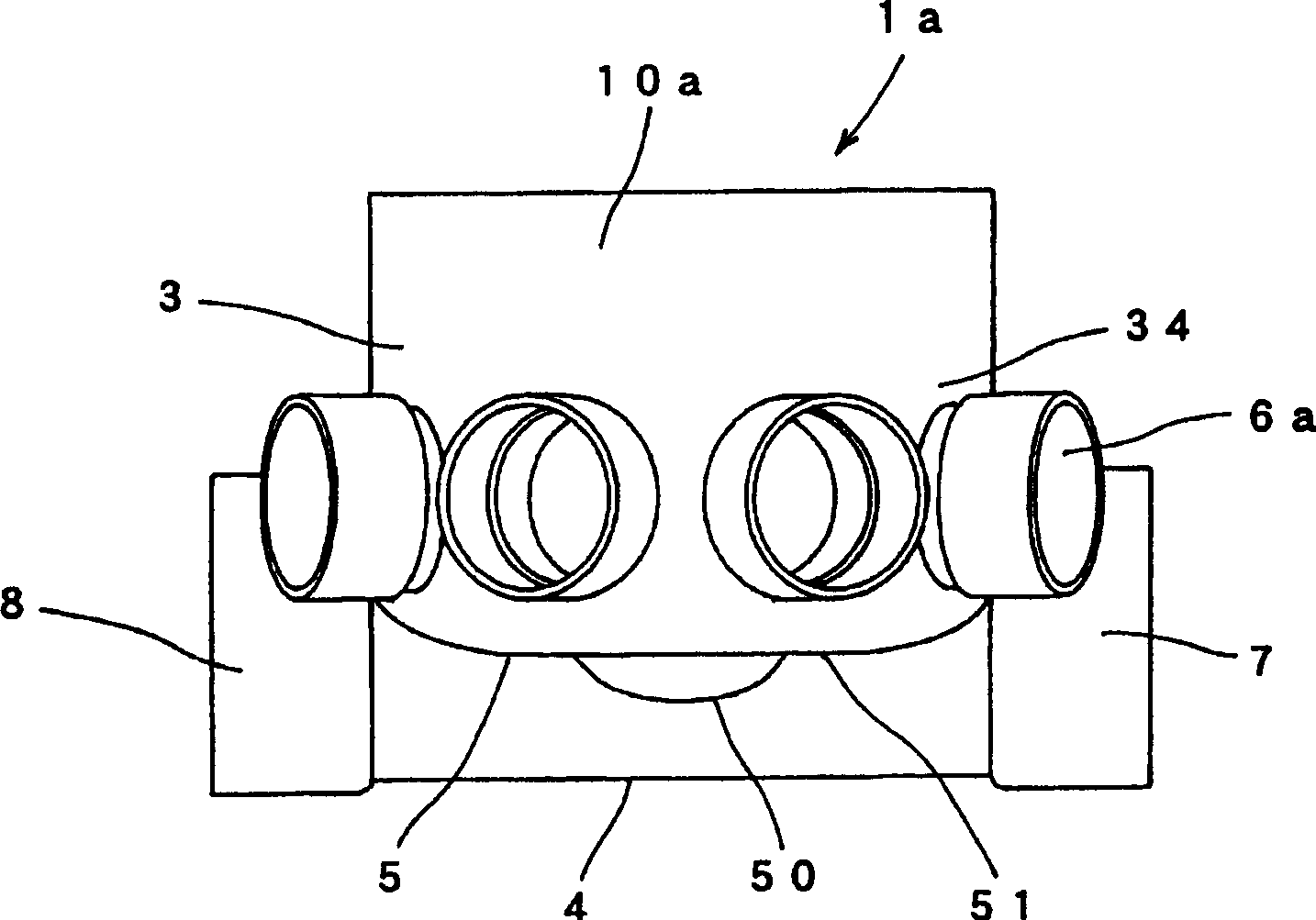

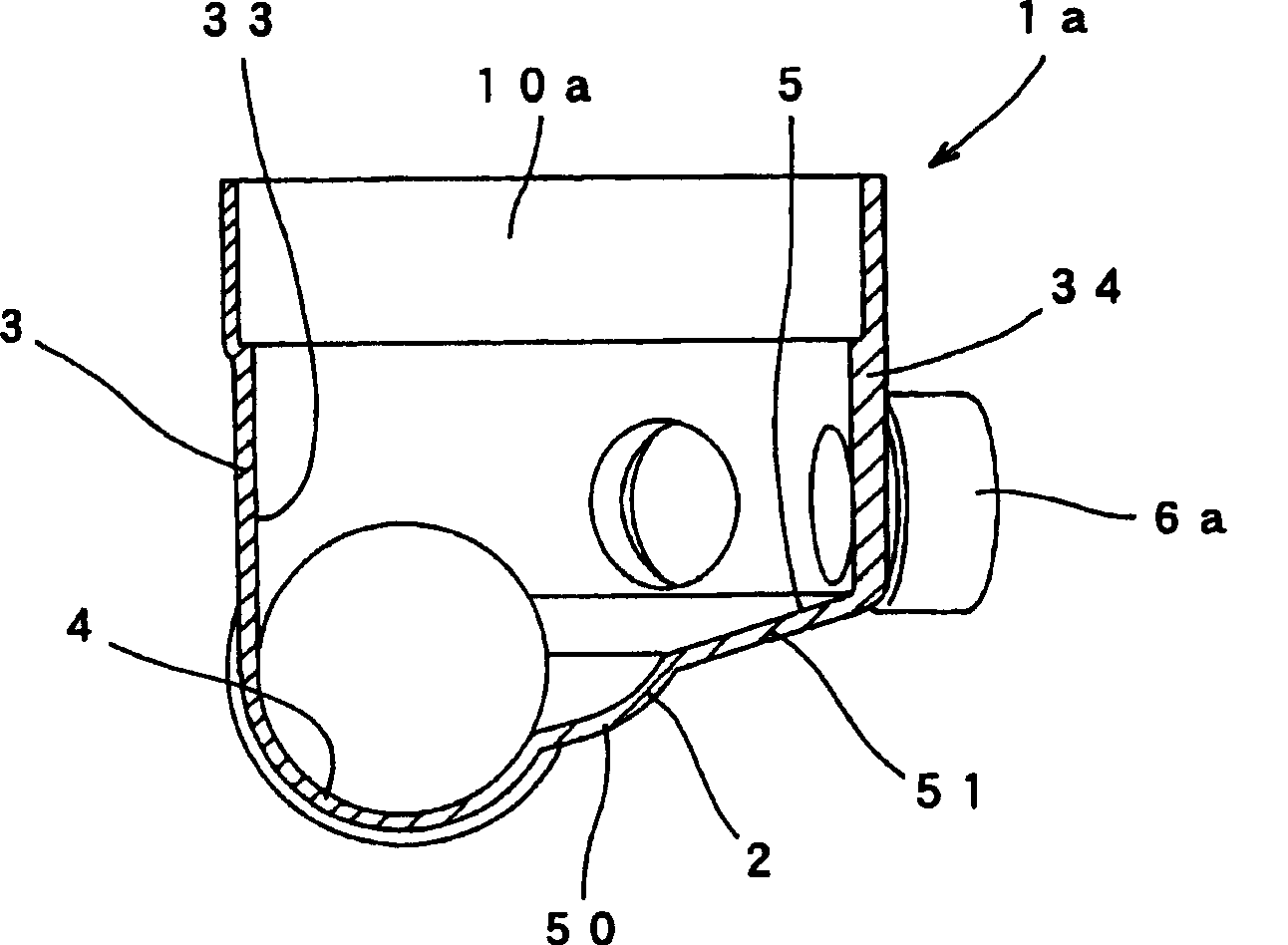

[0072] Example 1 is an example of a resin drainage tank according to the present invention in which four branch pipe inlets are arranged radially. figure 1 Is a top view when viewed from above, figure 2 Means figure 1 Side view. In addition, image 3 Expressed in figure 1 A cross-sectional view of the drain box of Example 1 cut from the A-A section.

[0073] If reference Figure 1 ~ Figure 3 It is explained that the resin drain bucket 1a of Example 1 is composed of a bottom 2 and a side wall 3. The bottom 2 is composed of a main turning groove 4 and an auxiliary turning portion groove 5, and the side wall 3 rises substantially vertically from the bottom 2.

[0074] The main revolving tank 4 is provided with a main pipe inflow port 7 and an outflow port 8 connected to the main pipe flow path at both ends, and the main pipe inflow port 7 and the outflow port 8 are arranged to reach the same height, in other words, through By arranging the main swing tank 4 horizontally, it is possi...

Embodiment 2

[0088] Example 2 is a modification of the resin drainage tank of Example 1 described above, and is an example of the resin drainage tank according to the present invention in which three branch pipe inlets are arranged radially. Therefore, the resin drain box of Example 2 differs from the drain box of Example 1 in the number or arrangement of the branch pipe inlets, the side wall of the drain box, the main turning groove, or the bottom including the auxiliary turning part, etc. , Its basic structure is the same as that of the drain box of Example 1.

[0089] Figure 4 This is a plan view of the resin drainage tank 1b according to the second embodiment of the present invention in which three branch pipe inlets 6b are arranged radially from above. In addition, the cross-sectional structure of its central part, except for the number or arrangement of branch pipe inlets 6b, is different from image 3 The structure shown is the same.

[0090] If reference Figure 4 and image 3 Explain...

Embodiment 3

[0105] Example 3 is another modification of the resin drain bucket of Example 1 described above. It is arranged in parallel to the flow direction of the drain in the main swing tank, and two branch inflow ports among the four branch inflow ports are arranged in parallel. An example of a resin drainage tank according to the present invention. Therefore, the resin drain tank of Example 3 differs from the drain tank of Example 1 in the arrangement of the branch pipe inlets, the side wall of the drain tank, the main turning groove, or the bottom including the auxiliary turning part, etc. The basic structure is the same as that of the drain box of the first embodiment.

[0106] Figure 5 This is the case of the resin drain bucket 1c according to the third embodiment of the present invention in which two of the four branch inflow ports 6c are arranged in parallel with respect to the flow direction 40 of the drain in the main turning tank when viewed from above Top view. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com