Combined harvester

A technology of combine harvester and body, applied in the direction of harvester, cutter, motor vehicle, etc., can solve the problem of harvesting grain stalk movement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

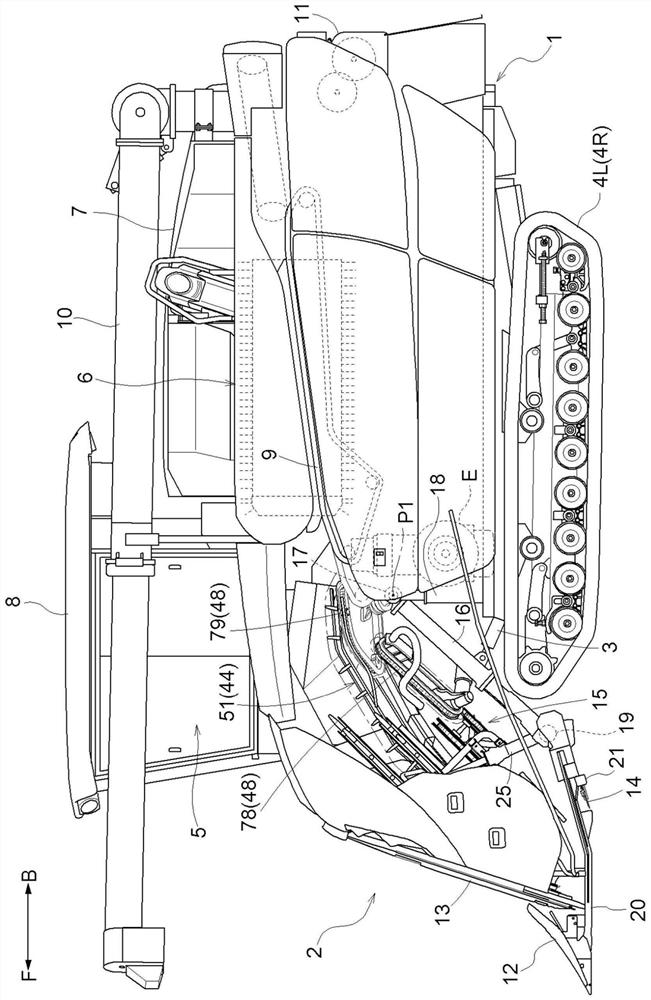

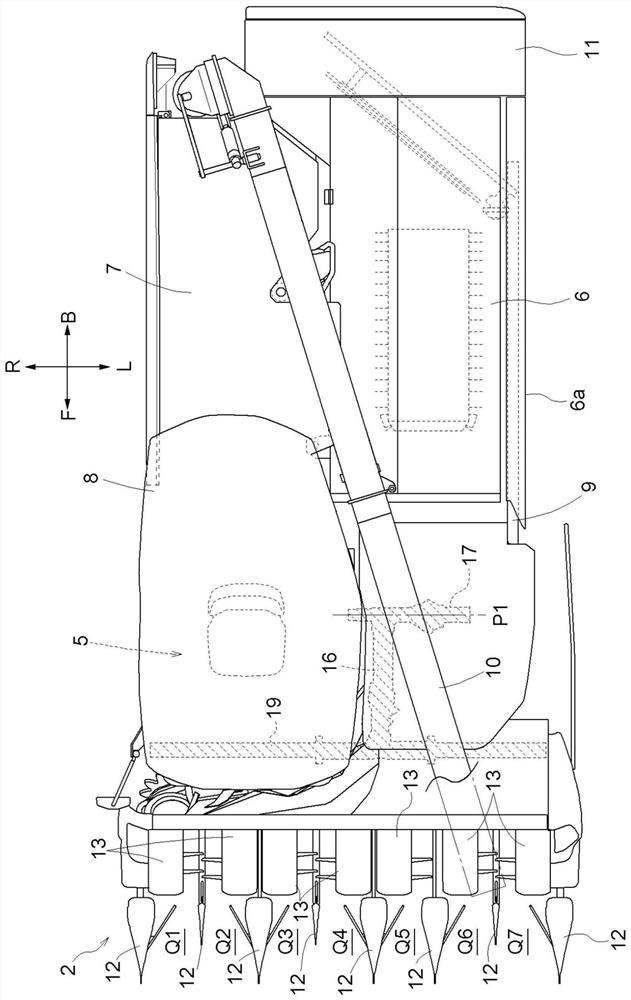

[0123] Hereinafter, embodiment of the combine which concerns on this invention is demonstrated based on drawing.

[0124] In this embodiment, figure 1 , 2 The direction indicated by the reference mark (F) in is the front side of the body, figure 1 , 2 The direction indicated by reference sign (B) in is the rear side of the body. figure 2 The direction indicated by the reference mark (L) in is the left side of the body, figure 2 The direction indicated by the reference mark (R) in is the right side of the body.

[0125] 〔the whole frame〕

[0126] Such as figure 1 , 2 As shown, the combine harvester of this invention is equipped with the harvesting part 2 which can harvest the traveling body 1 and seven upright grain stalks. The harvesting unit 2 is connected to the traveling body 1 so as to be able to swing up and down around the horizontal axis core P1, and is provided so as to be able to be driven up and down by the hydraulic cylinder 3 for raising and lowering.

...

no. 2 approach

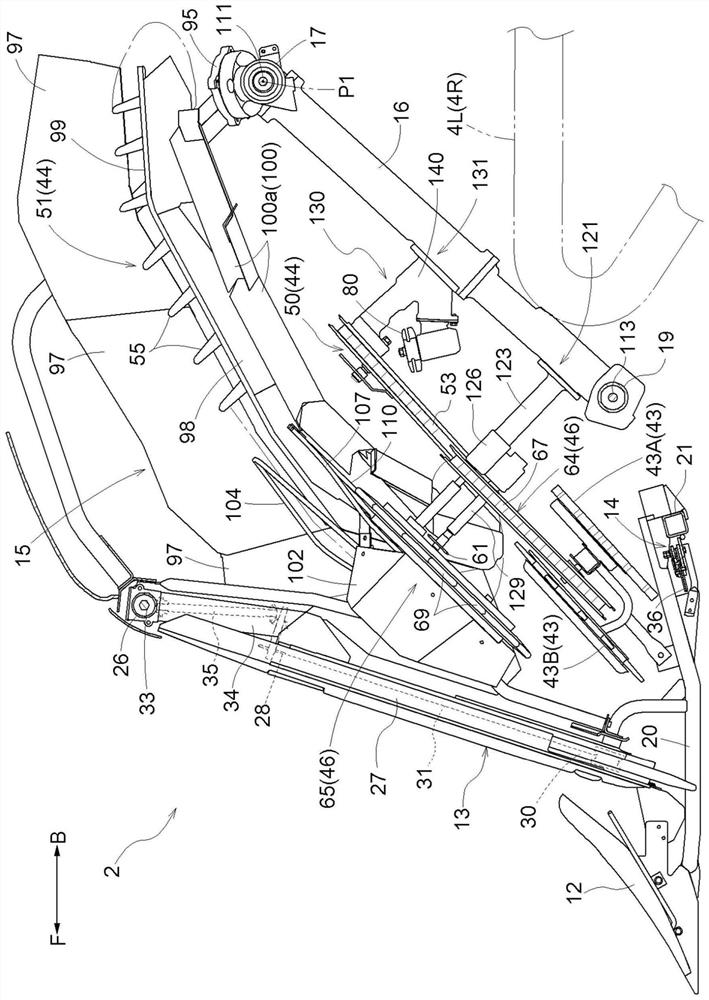

[0225] Hereinafter, embodiment of the combine which concerns on this invention is demonstrated based on drawing.

[0226] In this embodiment, Figure 23 , 24 The direction indicated by the reference mark (F) in is the front side of the body, Figure 23 , 24 The direction indicated by reference sign (B) in is the rear side of the body. Figure 24 The direction indicated by the reference mark (L) in is the left side of the body, Figure 24 The direction indicated by the reference mark (R) in is the right side of the body.

[0227] 〔the whole frame〕

[0228] Such as Figure 23 , 24 As shown, the combine harvester of this invention is equipped with the harvesting part 2 which can harvest the traveling body 1 and seven upright grain stalks. The harvesting unit 2 is connected to the traveling body 1 so as to be able to swing up and down around the horizontal axis core P1, and is provided so as to be able to be driven up and down by the hydraulic cylinder 3 for raising and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com