Toplift, heelpiece and shoe

A technology of top skin and base, applied in the field of top skin, can solve problems such as inability to ensure adhesion, small contact surface, complicated manufacturing process, etc., achieve excellent fixation, reduce slippage, and ensure cushioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

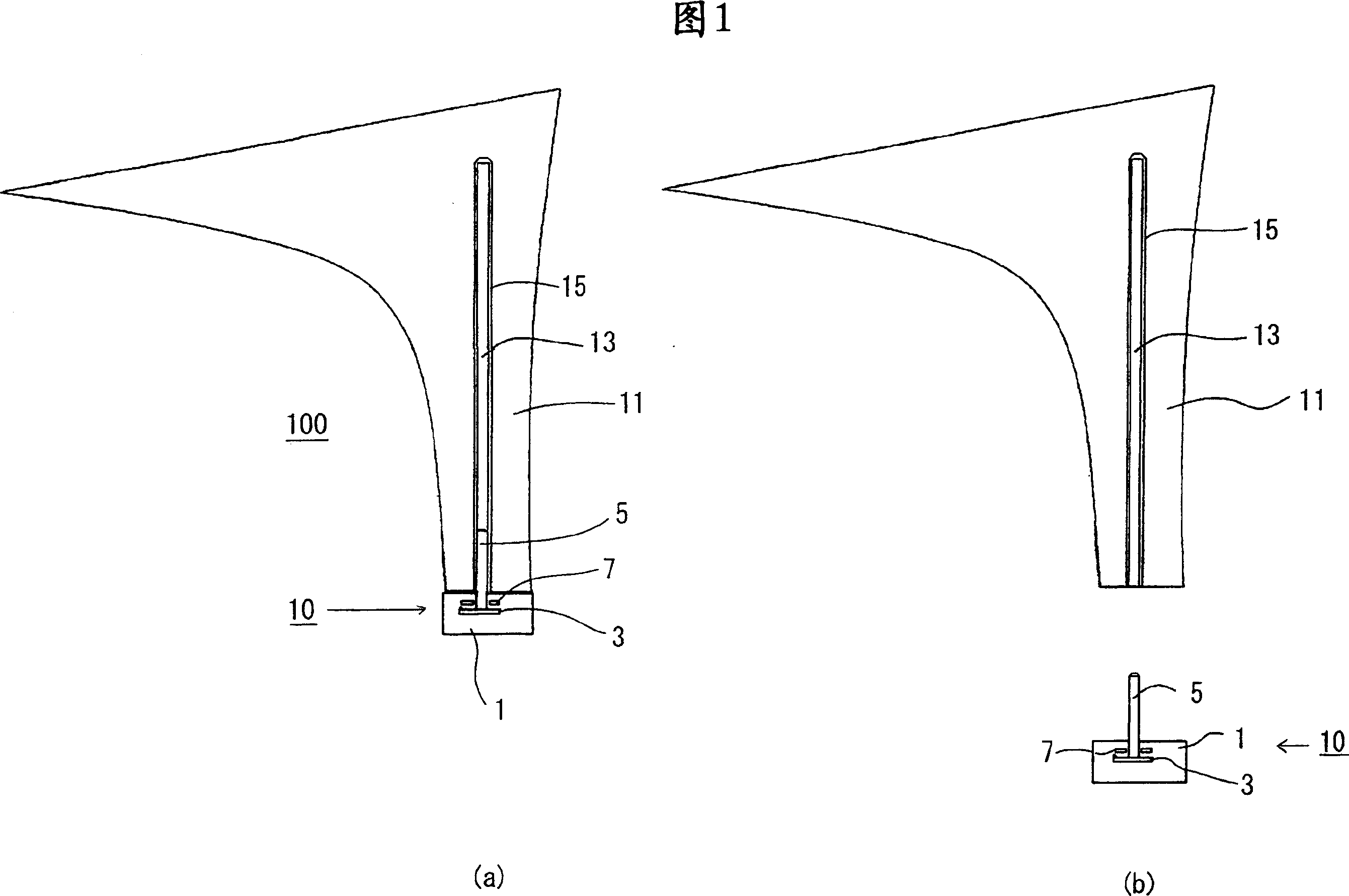

Image

Examples

Embodiment 1

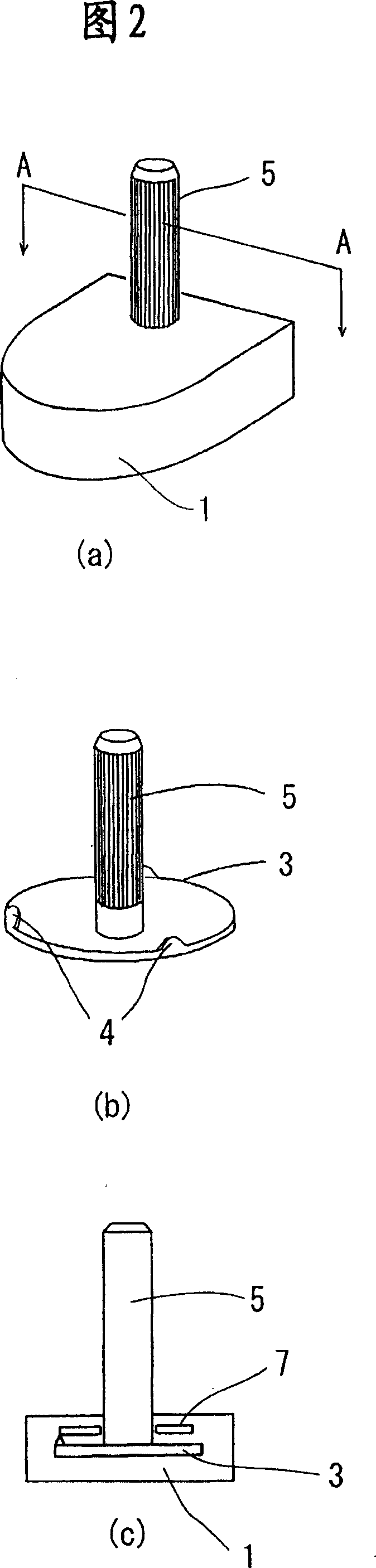

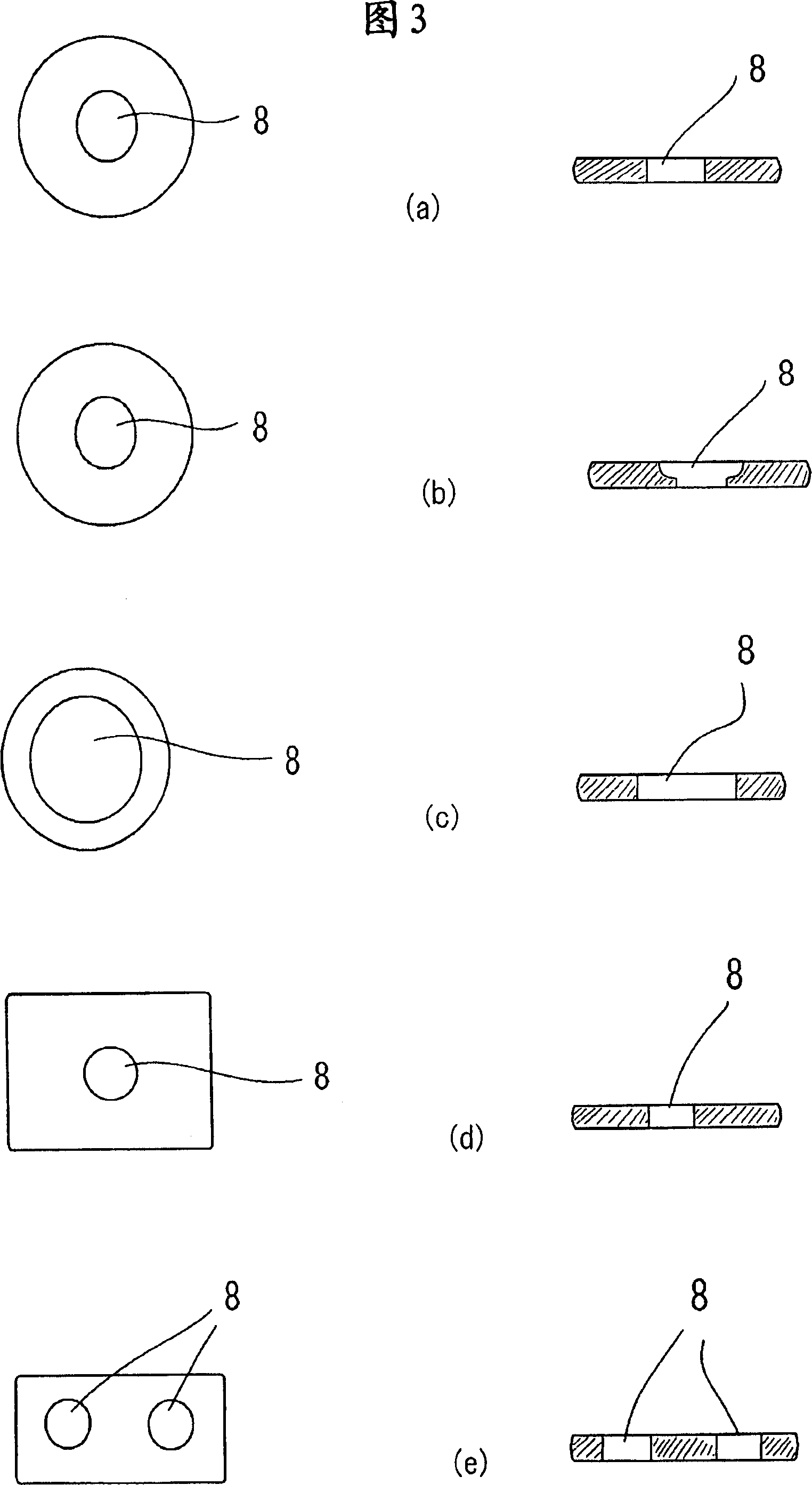

[0066] An intermediate member made of soft urethane resin containing 20% by weight of glass fiber is mounted on a mounting pin having a base portion with a diameter of 6 mm and a shaft portion with a diameter of 3.00 mm and a length of 13.0 mm protruding from the center of the shaft portion. (Hardness JIS A 90A) is a ring shape with a diameter of 9.0mm, an inner diameter of 2.985mm, and a thickness of 1.5mm. A square part with a width of 17.0mm x a length of 14.0mm x a height of 5.0mm is used as the main body of the sky and is inserted into the center. And the installation pin and the middle part are fixed. In addition, soft urethane resin (hardness JIS A 90A) is used for the main body of the sky skin.

[0067] Use three such sky skins, clamp the embedded shaft of the sky skin in the mold, clamp the sky skin body with a tester (dial type torque wrench, trade name "TONE / T3DN15"), rotate at 20mm per minute, and evaluate at the same time strength. The intensity at this time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com