Stainless-steel roll welding band-leading method

A technology for stainless steel and steel coils, applied in other manufacturing equipment/tools, metal rolling, manufacturing tools, etc., can solve the problems of long equipment occupation, large investment, easy damage to the surface of steel coils, etc., to reduce consumption and solve The effect of large investment and elimination of tension control difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

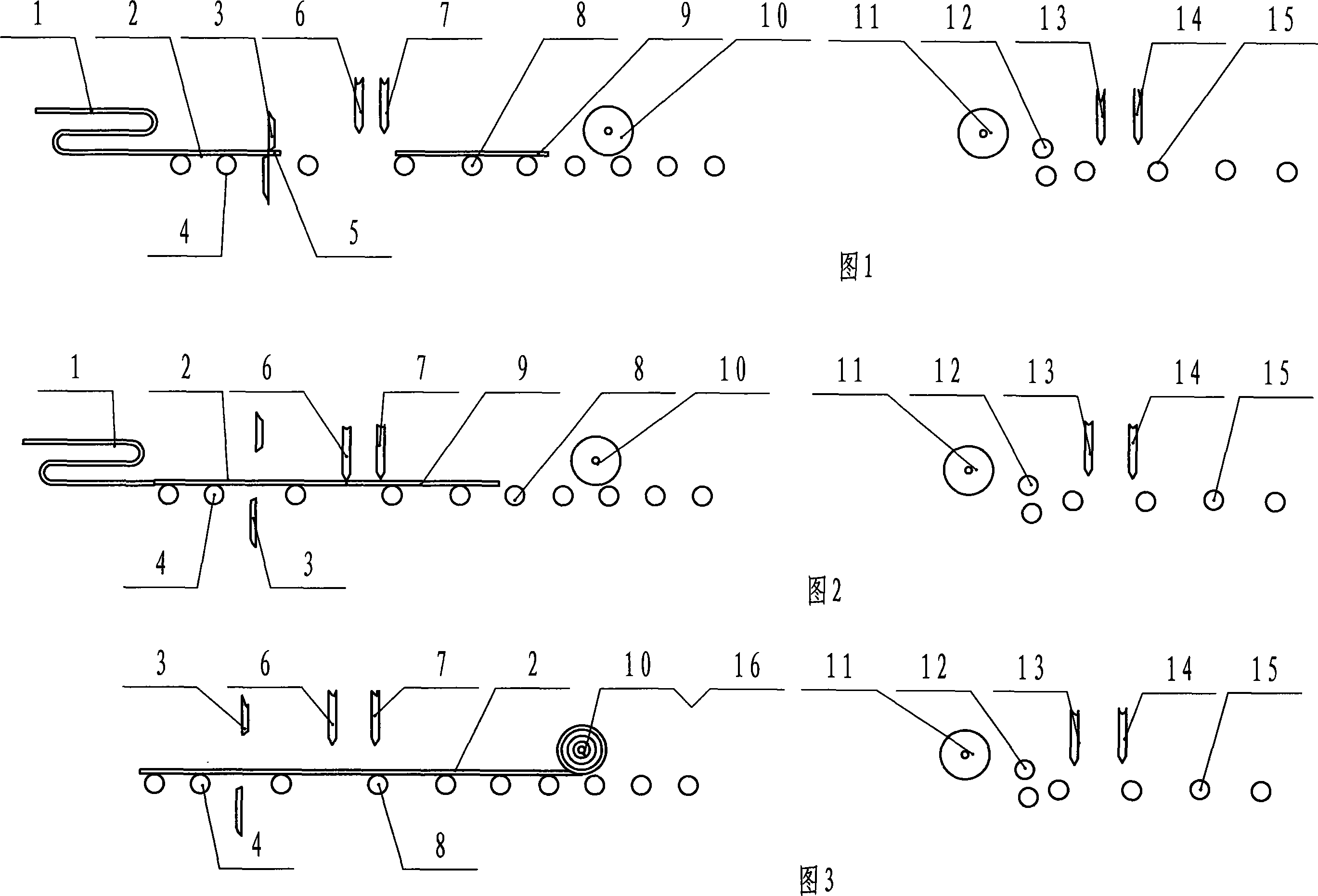

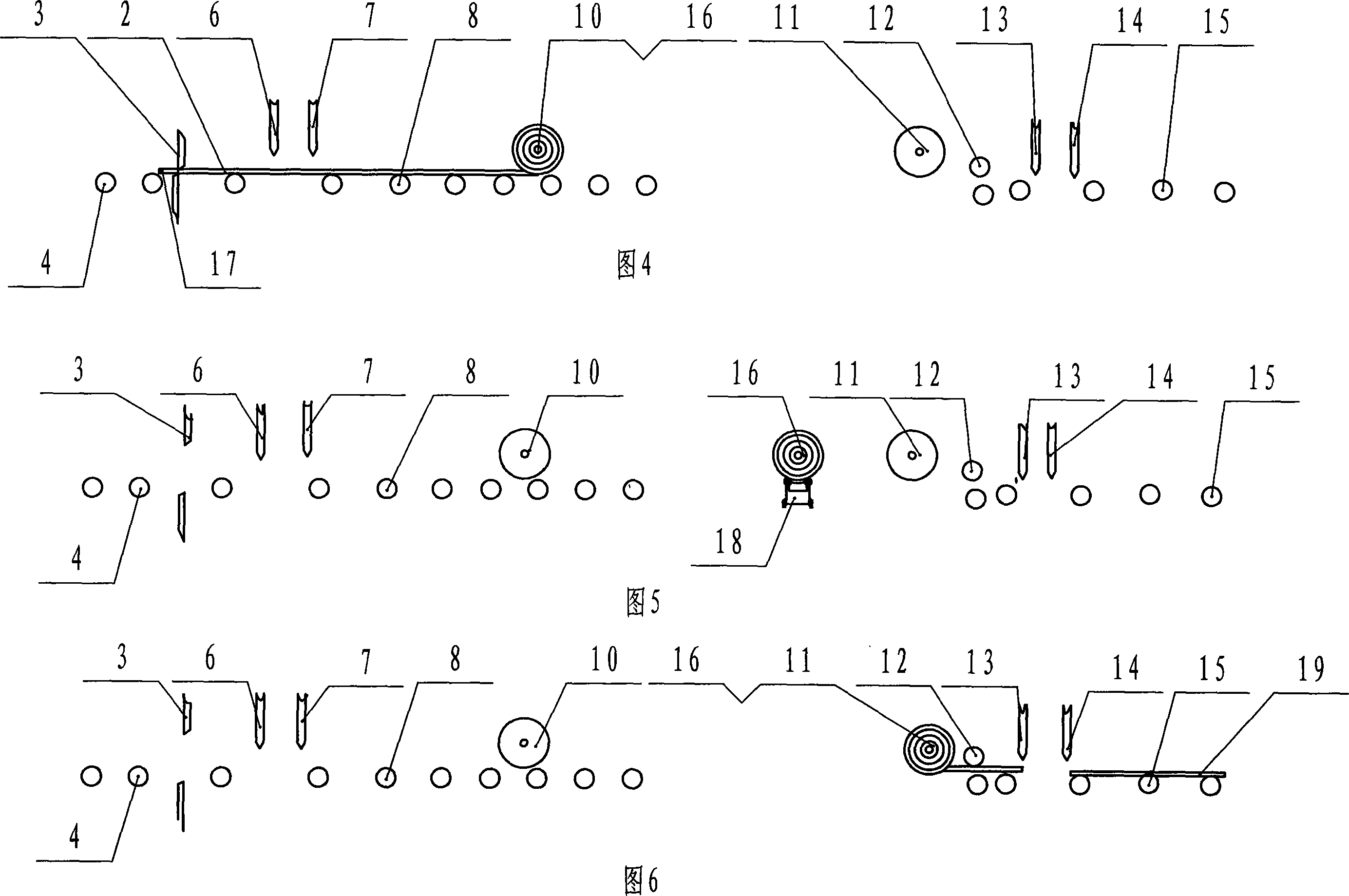

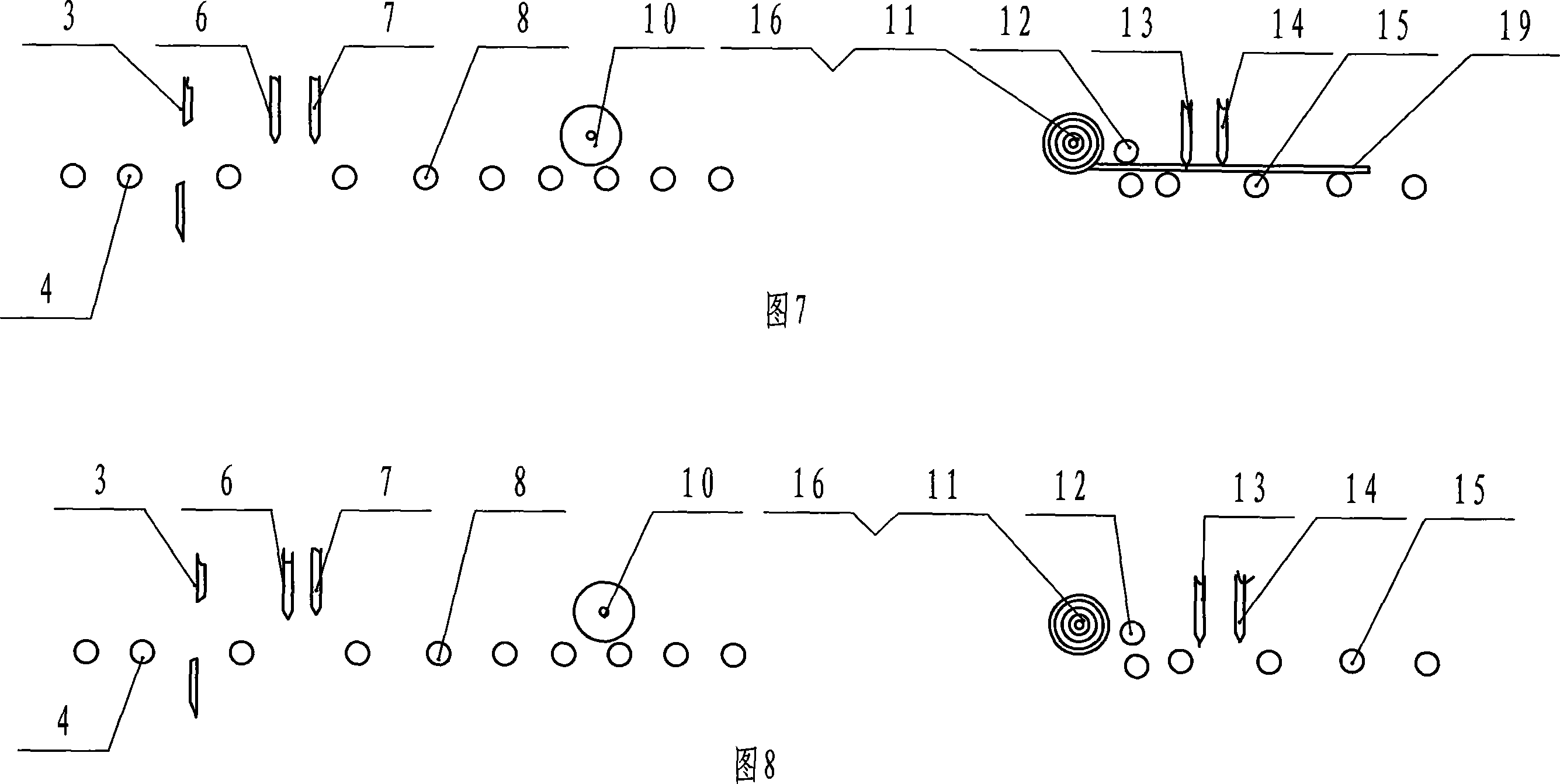

[0057] In this embodiment, a stainless steel strip with a width of 1500mm, a length of 260m, and a thickness of 8mm is welded to the unrolled stainless steel strip of the heat-treated OCr18Ni9 steel coil. The steps are as follows:

[0058] I Weld the head of the stainless steel strip at the tail of the raw material annealing and pickling line

[0059] 1) As shown in Figure 1, the stainless steel strip 2 runs to the material annealing and pickling line exit loading platform 4 after passing through the looper 1, and uses the parallel blade shearing machine 3 to cut the unreeled stainless steel strip 2 steel strip head 5 Cut off 200mm, so that the width of the cut steel strip head and the steel strip base material will be the same for welding;

[0060] 2) Put the OCr18Ni9 stainless steel lead strip 9 with a length of 10m, a width of 1500mm and a thickness of 6mm on the leading platform 8;

[0061] 3) As shown in Figure 2, align the front end of the lead strip 9 (left end in the figur...

Embodiment 2

[0080] The difference between this embodiment and the first embodiment is that the material of the lead strip 9 and the lead strip 19 is 1Cr17, and the material and welding steps of the stainless steel coil are the same as those of the embodiment.

Embodiment 3

[0082] The difference between this embodiment and the first embodiment is that the material of the lead strip 9 and the lead strip 19 is 2Cr13, and the material and welding steps of the stainless steel coil are the same as those of the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com