Disposable safety syringe

A safety syringe, a disposable technology, applied in the field of medical devices, can solve the problems of unsafe installation, unsafe patients, inconvenient installation, etc., and achieve the effect of convenient and safe assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

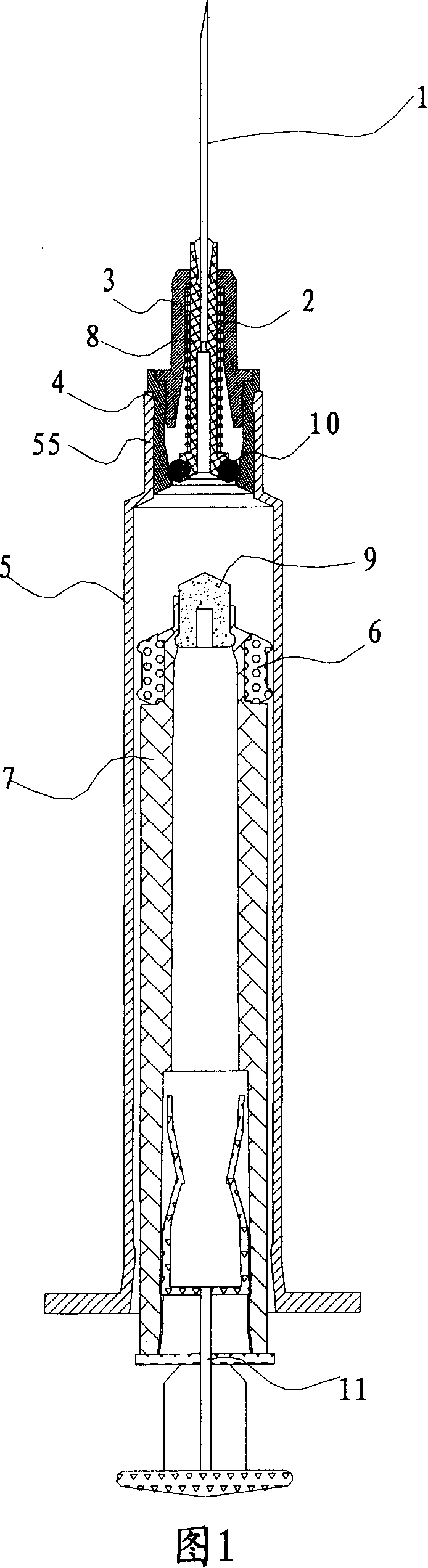

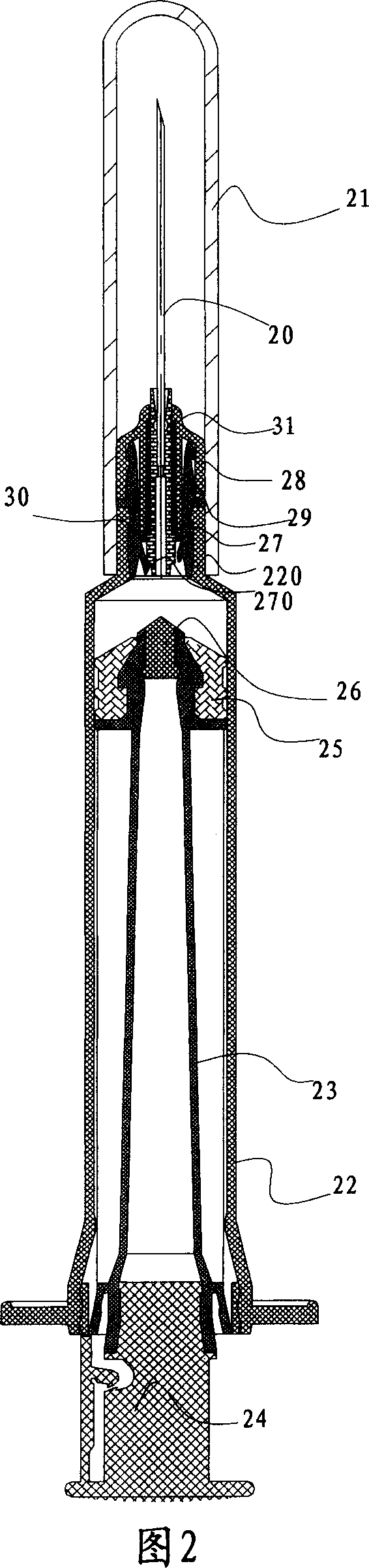

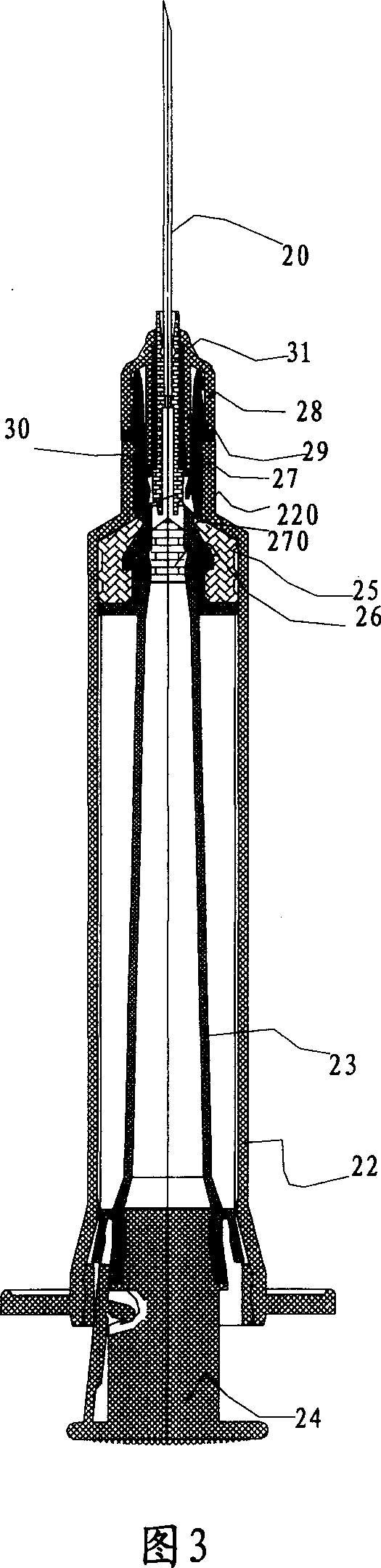

[0054]As shown in FIG. 2 and FIG. 5 , the disposable safety syringe of the present invention includes an injection needle 20 , a protective cover 21 for protecting the injection needle 20 , an injection syringe 22 and a barrel push rod 23 . in:

[0055] One end of the barrel-type push rod 23 extends into the injection syringe 22, and the other end extends out of the injection syringe 22. A push end 24 is provided at the outer end extending out of the injection syringe 22, and it extends into the injection syringe 22. One end of the peripheral sealing sleeve has a sealing rubber ring 25, the sealing rubber ring 25 can move inside the injection syringe 22 under the push of the cylindrical push rod 23 and can prevent the backflow of the medicinal liquid and push the medicinal liquid into the injection needle tube 2 A piston 26 that can be retracted into the inside of the barrel push rod 23 with the retraction of the injection needle tube 20 is provided at the front end of the bar...

Embodiment 2

[0060] The disposable safety syringe in this embodiment is based on the disposable safety syringe in Embodiment 1, which improves the structure of the pressure spring plug 28 and the needle seat cover 27, making the syringe safer in use and more convenient and safe in assembly . As shown in Figures 5 to 9, the needle seat cover 27 is provided with at least two plastic fitting sheets 276 on the top of its hollow cylinder, and barbs 275 are arranged on the top outer periphery of the fitting sheets 276, and outside the middle part of the cylinder A flange or a groove 272 is provided on the edge for sealing and fixing with the front-end fixing device 220 of the injection syringe 22 , and a barb 270 is provided on the inner edge of the bottom of the cylinder for fixing the needle holder 31 . The compression spring plug 28 includes an insertion part 280 inserted into the inside of the needle seat cover 27 and a positioning part 281 which is arranged on the outside of the insertion p...

Embodiment 3

[0062] The structure of the disposable safety syringe in this embodiment is basically the same as that in Embodiment 2, and is based on the structural improvements of the compression spring plug 28 and the needle seat cover 27 on the basis of Embodiment 1, so that the syringe is safer and easier to use. It is more convenient and safe to assemble. As shown in Figures 10 to 14, the needle seat cover 27 is provided with a ring of barbs 271 on the outer edge of the top of the hollow cylinder, and is provided with a fixing device 220 for sealing with the front end of the injection syringe 22 on the outer edge of the middle part of the cylinder. A fixed flange or groove 272 is provided with a barb 270 on the inner edge of the bottom of the cylinder for fixing the needle hub 31 . The compression spring plug 28 includes an insertion part 280 inserted into the inside of the needle seat cover 27 and a positioning part 281 which is arranged on the outside of the insertion part 280 and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com