Zero-leakage hydraulic load-equalizing cylinder for freight train

A railway freight car, zero leakage technology, applied in the field of hydraulic equal load cylinder, can solve the problems that cannot meet the use requirements of railway general freight cars, achieve the effect of reliable function and meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

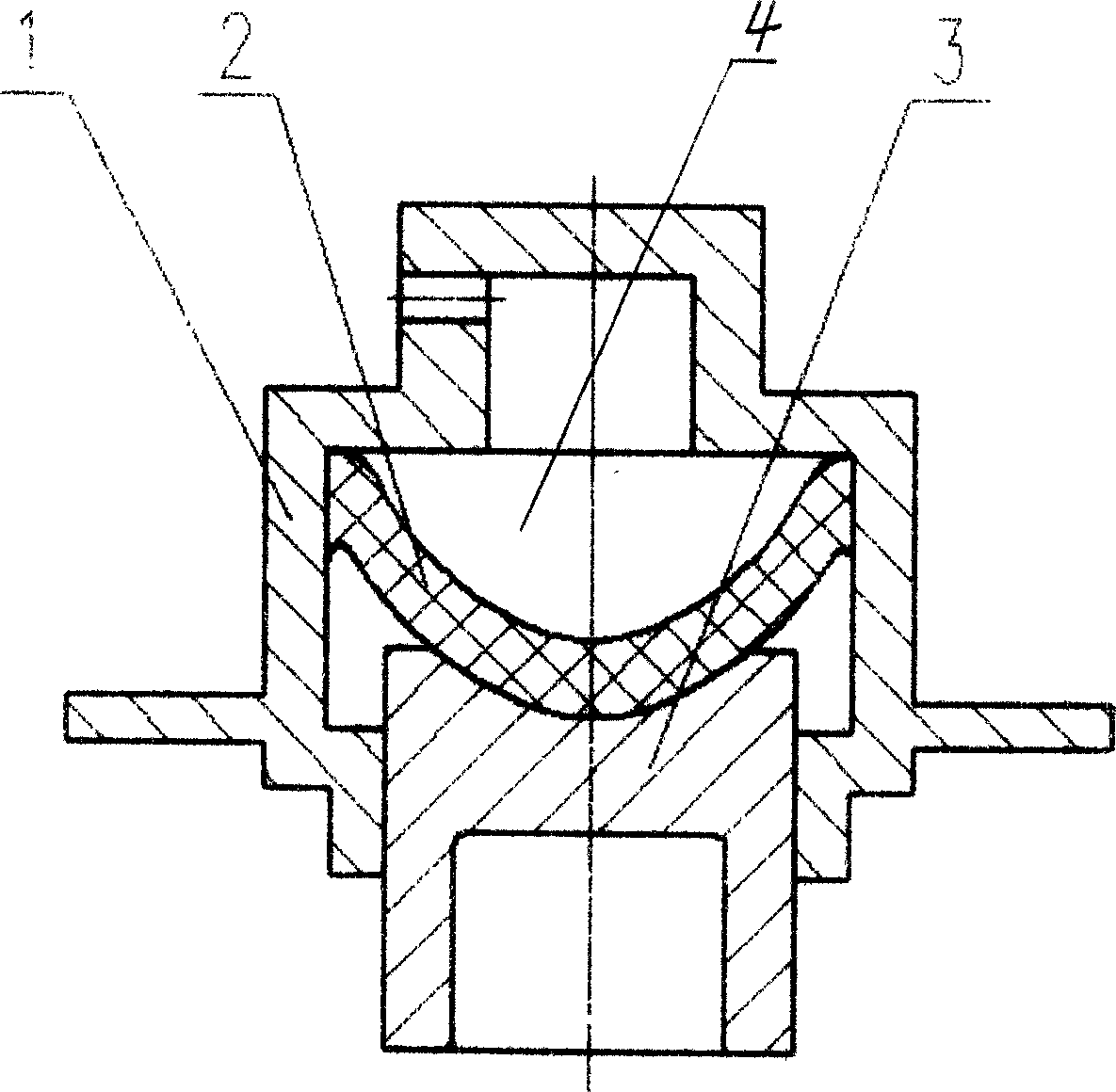

[0009] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0010] Referring to the accompanying drawings, the present invention includes a cylinder body, a rubber diaphragm and a plunger, and is characterized in that: the lower end of the rubber diaphragm 2 is closely attached to the plunger 3, and the upper end is fixedly connected with the cylinder body 1, and the cylinder body 1 and the rubber diaphragm 2 form a sealed working chamber 4 for storing hydraulic media.

[0011] The volume change of the hydraulic medium in the sealed working chamber 4 pushes the plunger 3 to reciprocate up and down through the rubber diaphragm 2 and adapts to the rolling deformation of the rubber diaphragm 2 . There are no friction and wear factors between the plunger and the sealing ring of the traditional hydraulic cylinder, so the hydraulic cylinder can achieve zero leakage. The utility model has re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com