Mold clamping force detection method

A detection method and a clamping force technology, applied in the field of clamping force detection for detection of clamping force, can solve the problem that the detection of clamping force does not require much accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

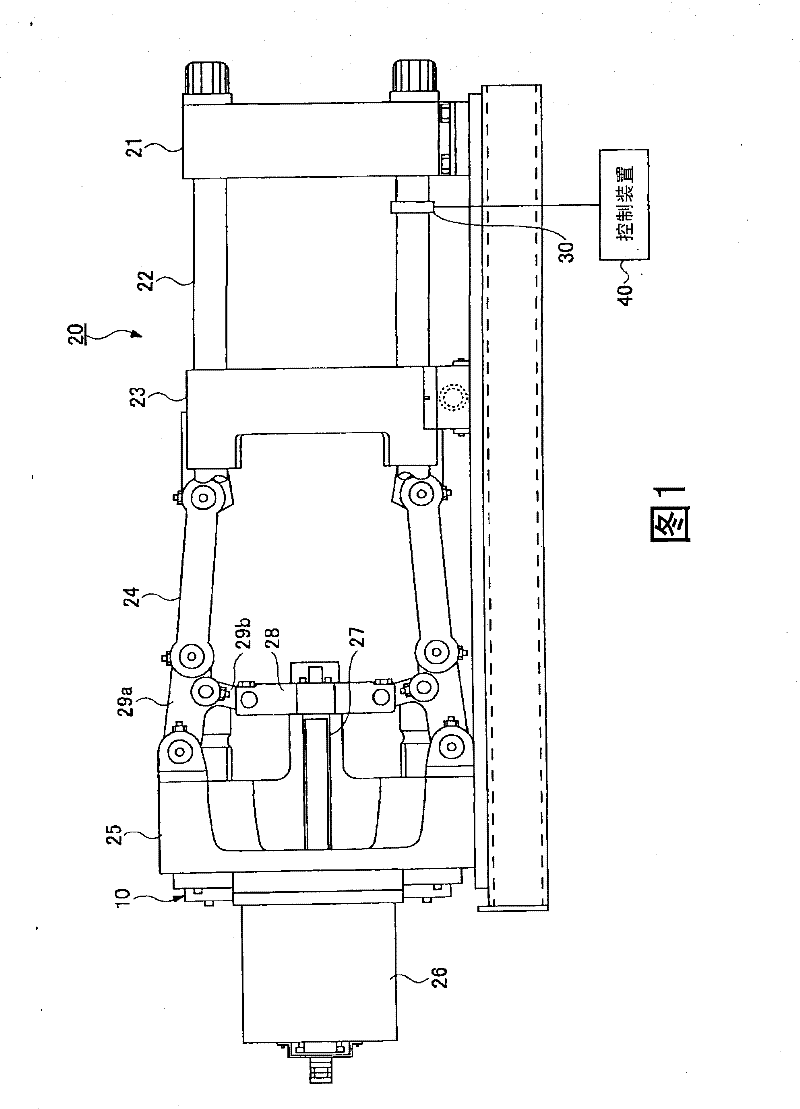

[0045] Hereinafter, as a device that can use the deformation detection device of the present invention, for the mold clamping device of an injection molding machine, refer to figure 1 Simply put.

[0046] figure 1 It is a side view of the mold clamping device of the injection molding machine equipped with the deformation detection device of the present invention. figure 1 The shown mold clamping device has a mold thickness adjusting device 10 and a mold clamping mechanism 20 . The mold clamping mechanism 20 is a toggle-type mold clamping mechanism, and has a fixed plate 21, a tie rod 22, a movable plate 23, an arm 24, a toggle support portion 25, a mold clamping servo motor 26, a ball screw 27, and a crosshead. 28.

[0047] A fixed die (not shown) is attached to the fixed plate 21 , and a movable die (not shown) is attached to the movable plate 23 . By moving the movable plate 23 along the tie rods 22, the movable mold is moved relative to the fixed mold to perform mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com