Accurate installation process for oversea bridge binding beam 0# section

A technology for precise installation and sea-crossing bridges, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of low precision of floating cranes and achieve the effect of convenient position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This sea-crossing bridge combines the precise installation process of the 0# section of the beam, and the process method is as follows:

[0027] An accurate installation process for the 0# section of the joint beam of a cross-sea bridge is characterized in that the process method is as follows:

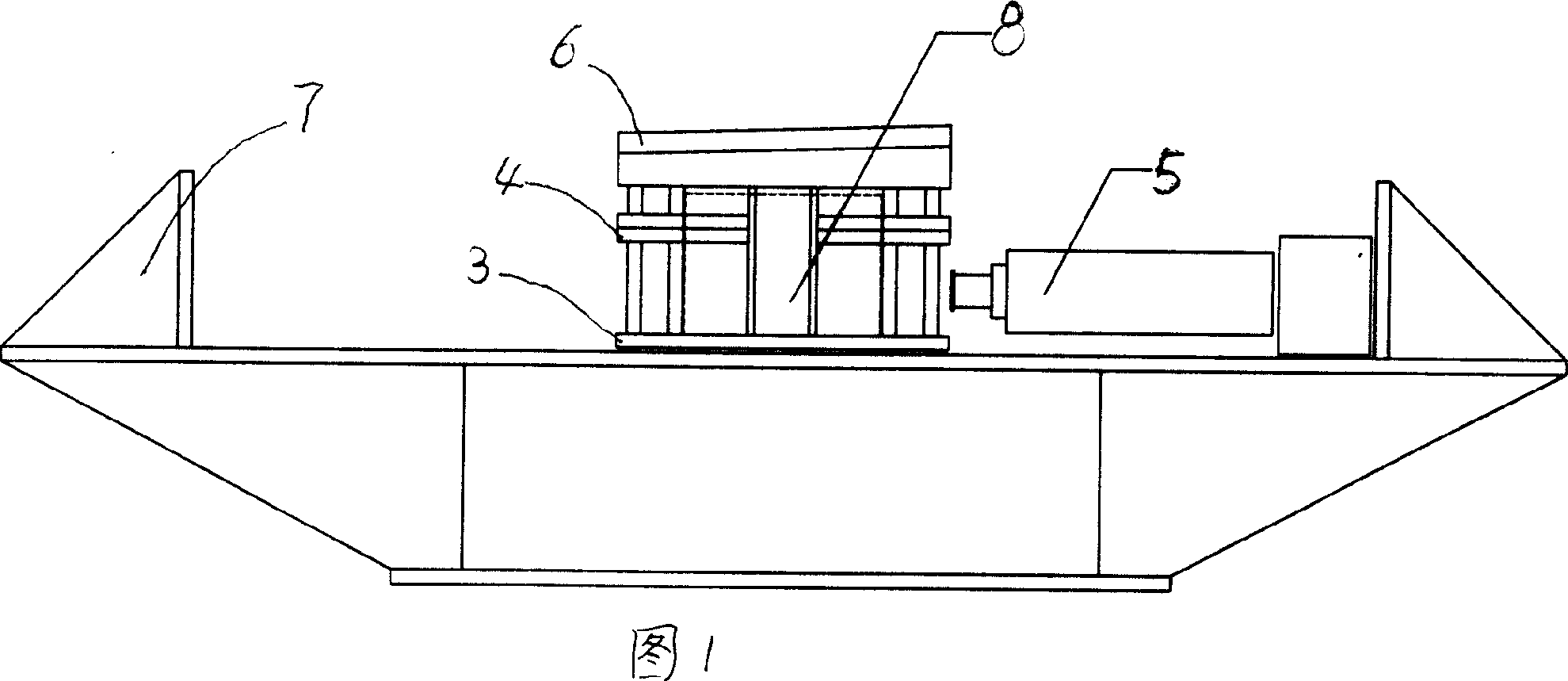

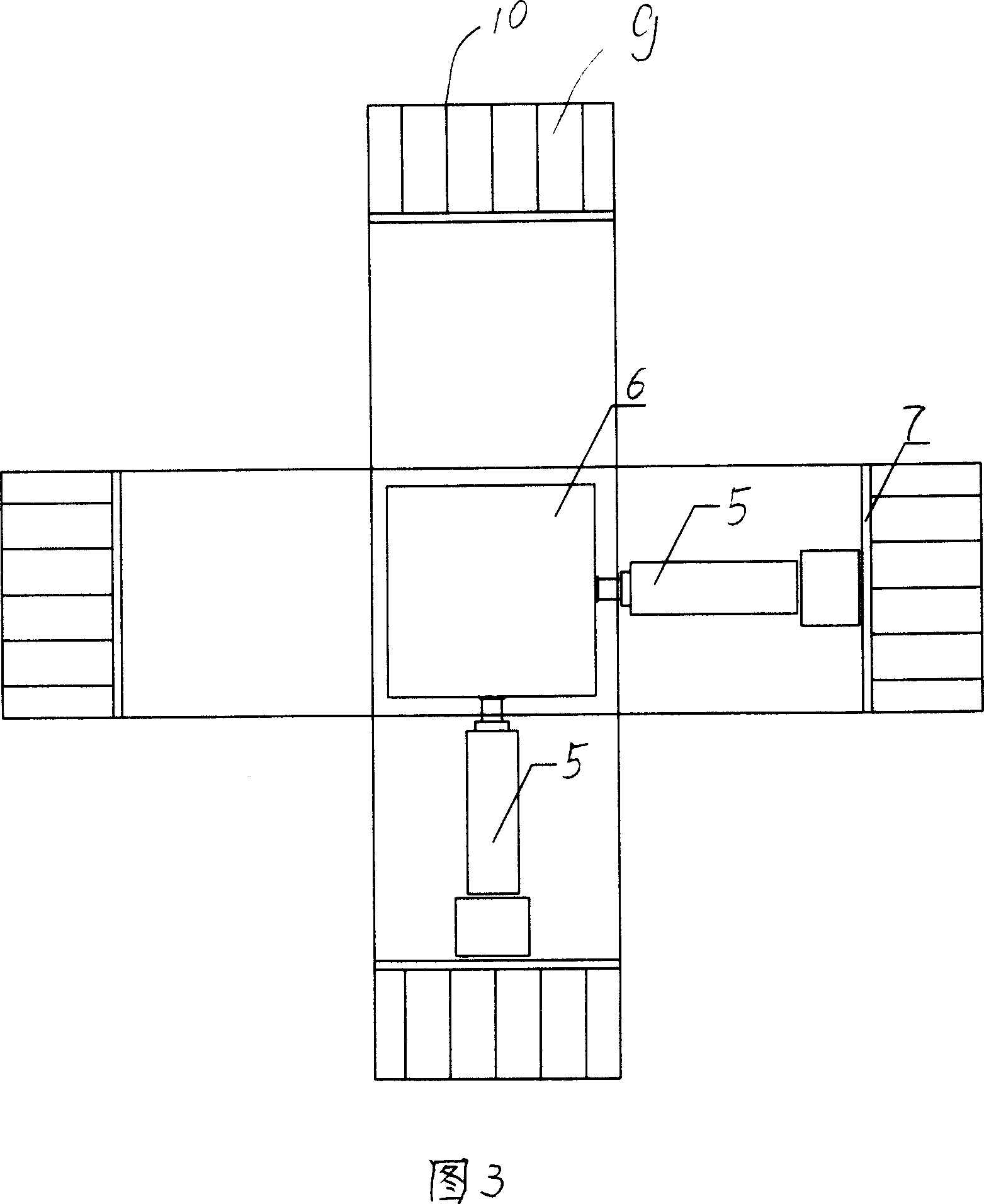

[0028] ① According to the geometric dimensions of the beam section, set up the 0# section bent frame at the position of the 0# section beam; the 0# section bent frame is composed of steel pipes, and the channel steel 12 is fixed and connected horizontally between the two steel pipes 11; the top of the steel pipe is double-shaped The steel beams are connected by 13, and two combined beam temporary supports and two three-way adjustment devices are installed on each longitudinal double-height steel beam;

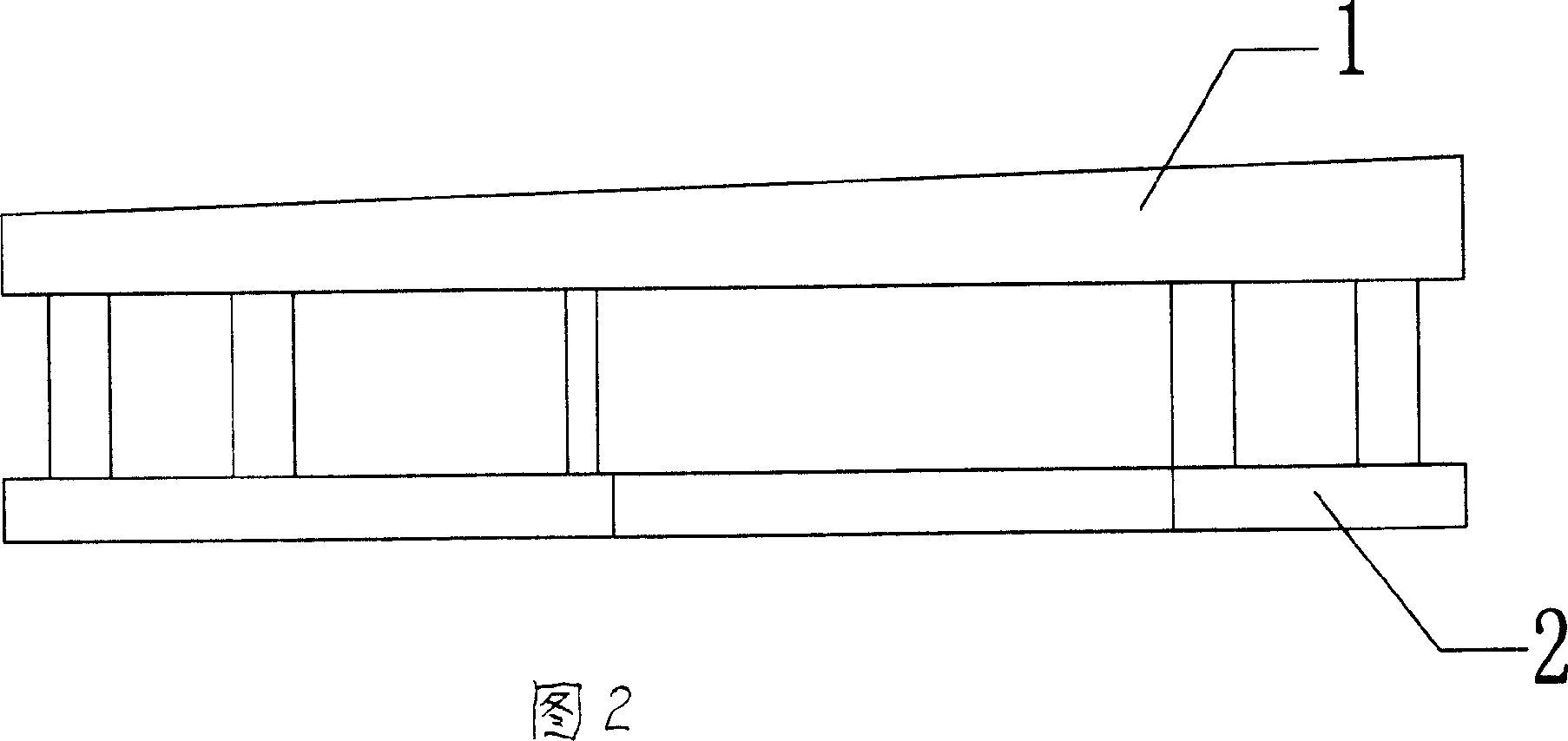

[0029] The structure of the temporary support is that the bottom is a steel block 2, and the plate rubber support 1 is placed on the steel block; the inclination angle of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com