Combined device for measuring wet steam flow and dryness and measuring method thereof

A measuring device and wet steam technology, which is applied in the direction of measuring fluid flow by measuring pressure difference, volume/mass flow rate generated by mechanical effects, and material moisture content, etc., which can solve the problems of slow parameter calculation speed and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

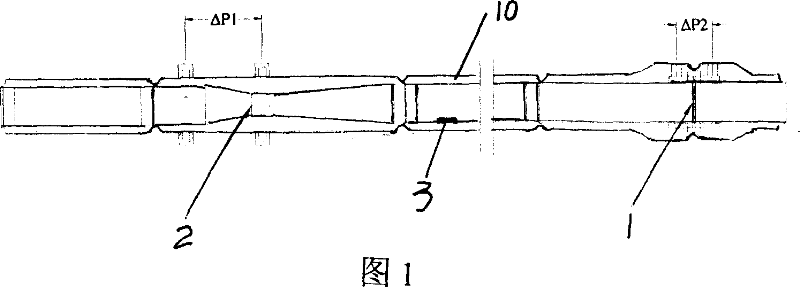

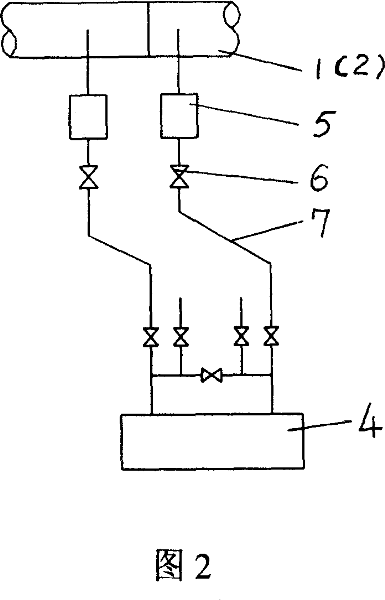

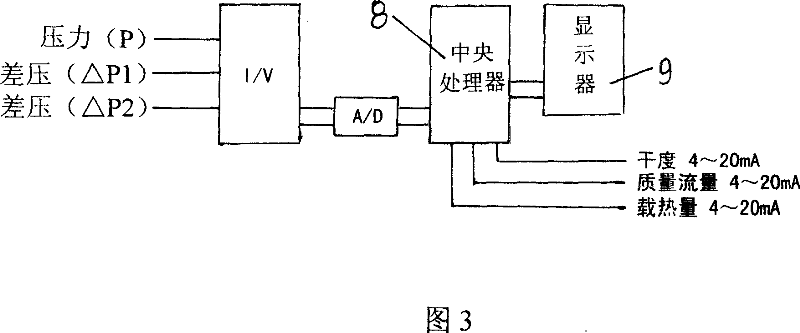

[0078] Please refer to Fig. 1 and Fig. 2, the present invention is composed of a standard orifice plate 1, a Venturi tube 2, a high-precision pressure sensor 3, an intelligent differential pressure transmitter 4, a condenser 5, a pressure taking valve 6, a pressure guide Tube 7, CPU 8, and display 9. The standard orifice plate 1 and the Venturi tube 2 are connected in series in the wet steam pipeline 10. The positive and negative pressure outlet tubes of the standard orifice plate 1 and the Venturi tube 2 are respectively connected to the condenser 5. The pressure guide tube 7 is connected with the pressure taking valve 6, the pressure guide tube 7 is connected with the intelligent differential pressure transmitter 4, and the sampling point of the high-precision pressure sensor 3 is set between the standard orifice plate 1 and the Venturi tube 2 In the wet steam pipeline 10 between them, the signals of the high-precision pressure sensor 3 and the intelligent differential pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com