Pll control circuit of optical disc apparatus, and program for controlling the optical disc apparatus

一种控制电路、光盘装置的技术,应用在功率的自动控制、光盘、电气元件等方向,能够解决性能低下、延迟、耗电增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

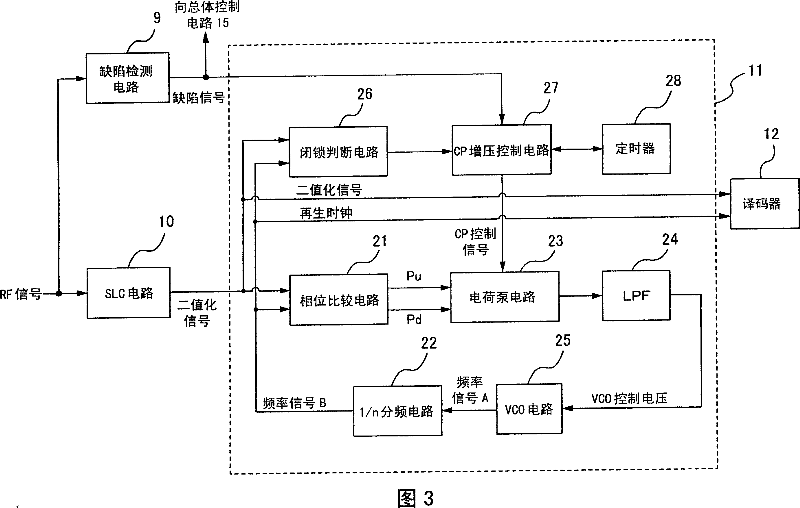

[0026] At least the following matters are clarified from the description in the specification and the drawings.

[0027] (Overall configuration of the optical disc device)

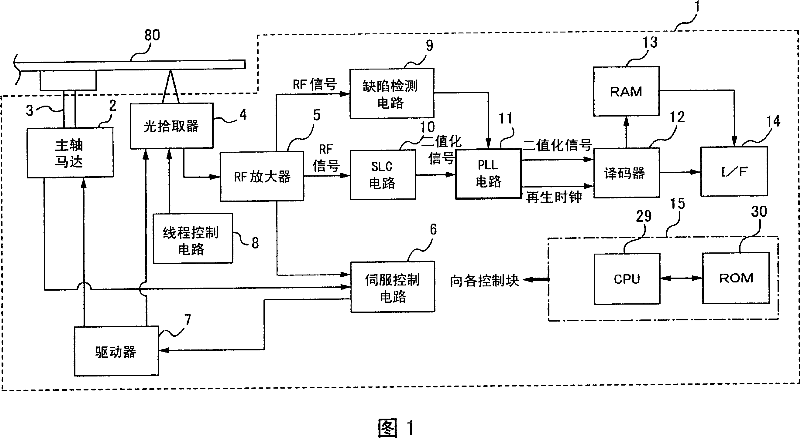

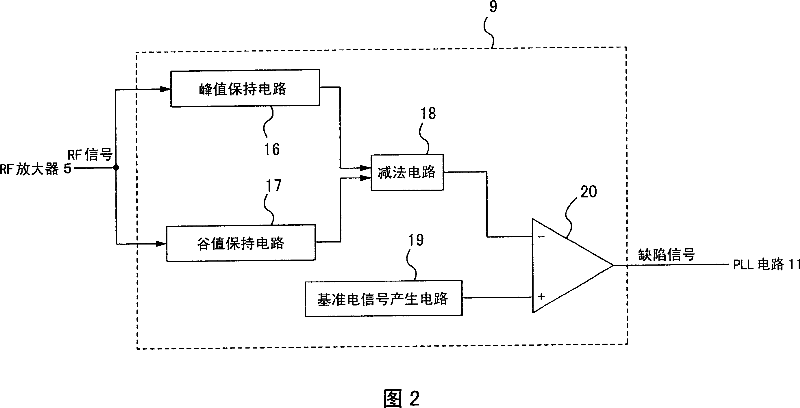

[0028] Referring to FIG. 8 as appropriate, the overall configuration of an optical disc device 1 having a PLL control circuit 11 according to the present invention will be described using FIGS. 1 and 2 . FIG. 1 is a functional block diagram showing an example of the overall configuration of an optical disc device 1 according to the present invention. FIG. 2 is a functional block diagram showing an example of the configuration of the defect detection circuit 9 (first detection circuit) shown in FIG. 1 . In addition, in this embodiment, the optical disc 80 which is the target of information reproduction, for example, CD standard is demonstrated as an example.

[0029] The optical disk device 1 includes a spindle motor 2, a rotating shaft 3, an optical pickup 4, an RF amplifier 5, a servo control circuit 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com