Thrum yarn shuttle mouth forming device in loom

A shed and loom technology, applied to the selvedge opening mechanism, looms, textiles, etc., can solve the problem that the gap cannot be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

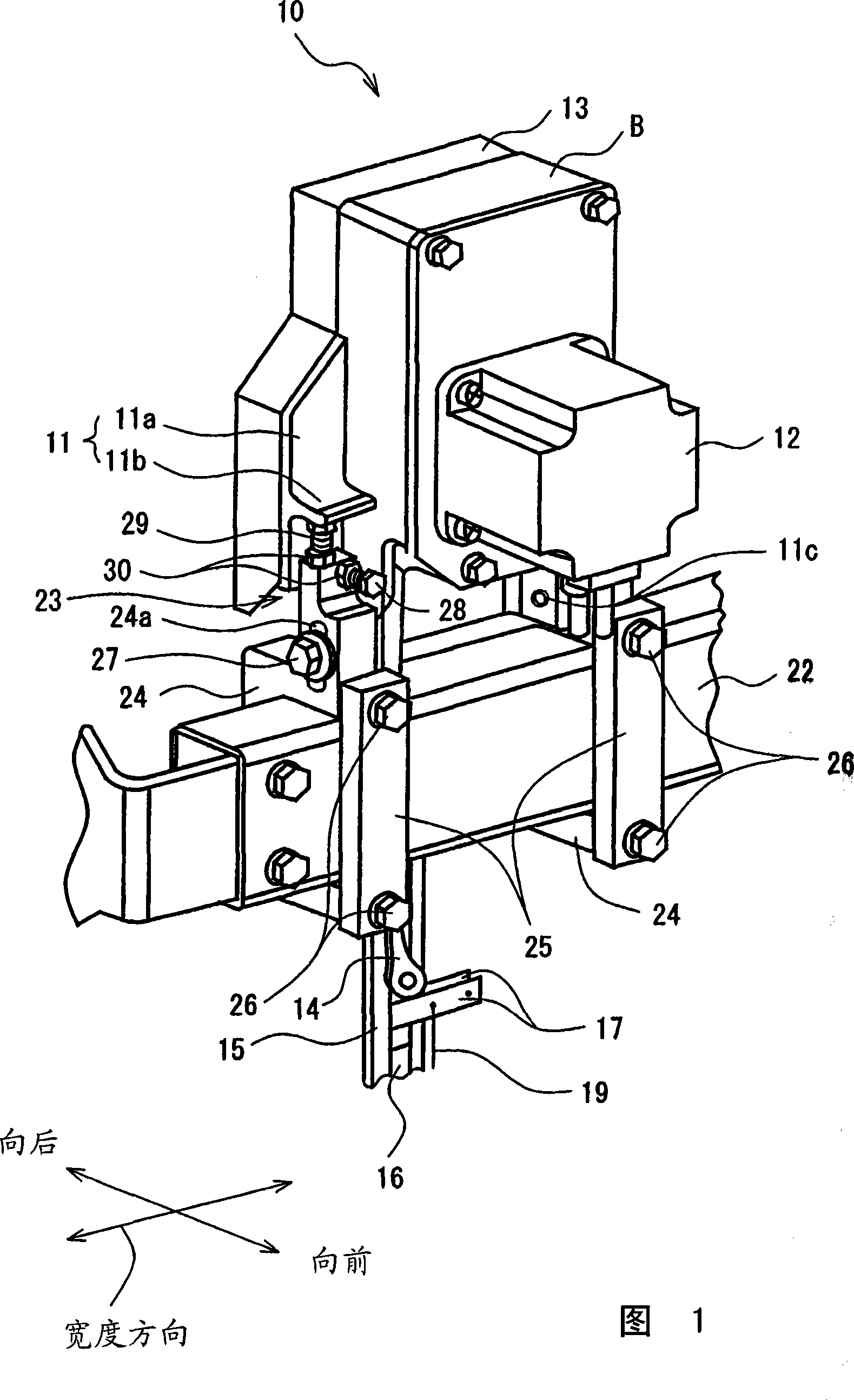

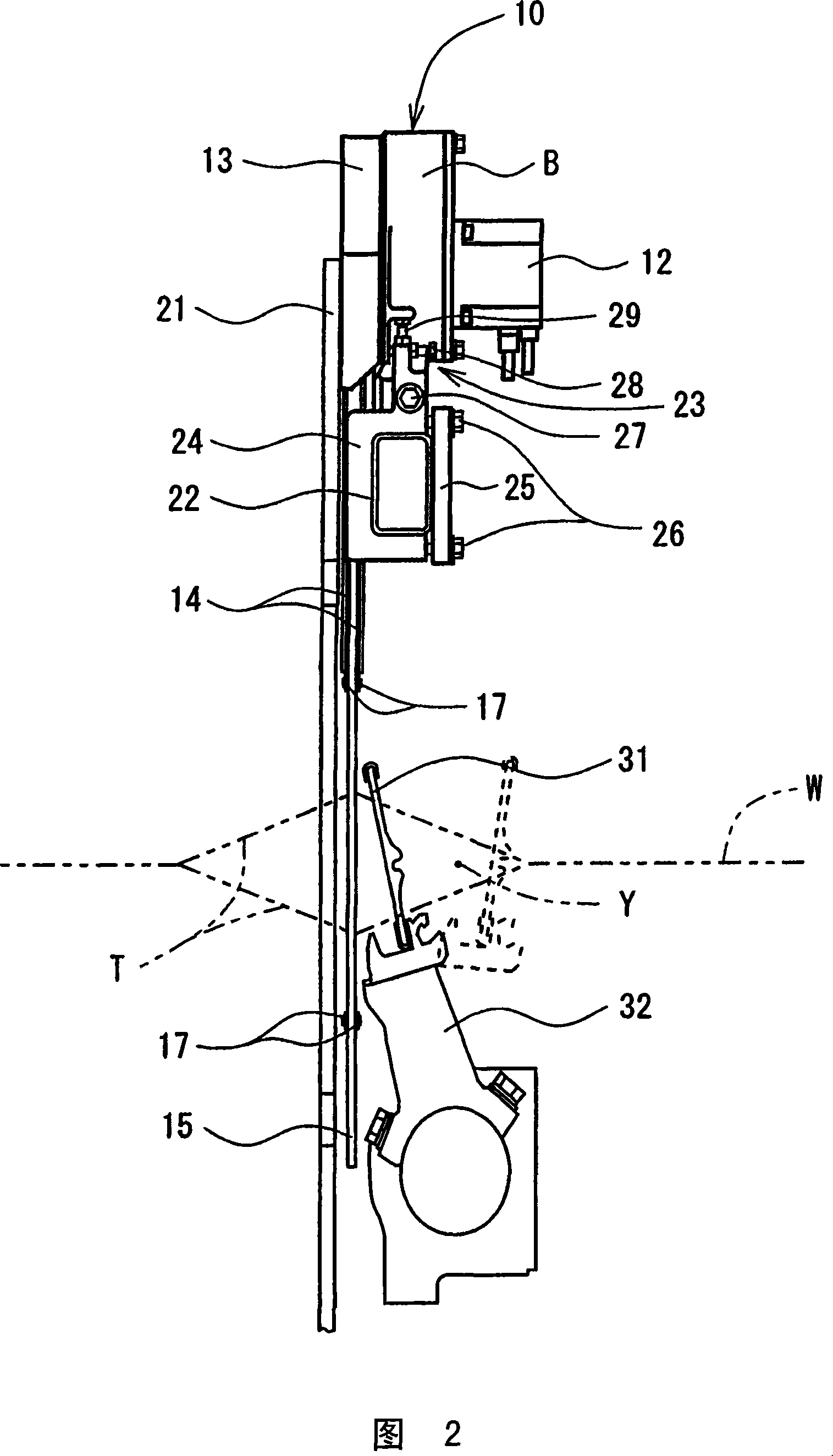

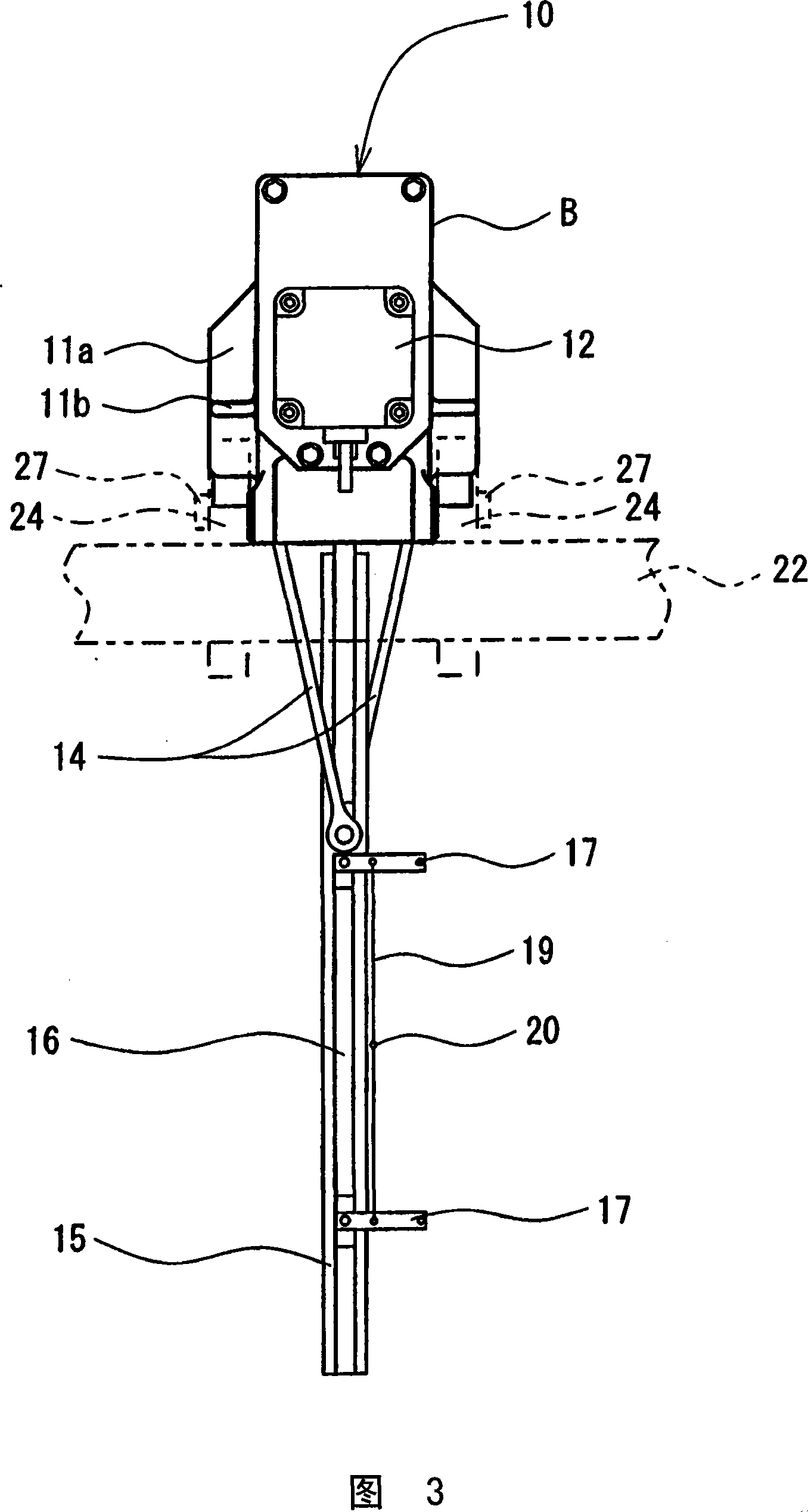

[0018] The first preferred embodiment of the selvedge yarn shed forming device of the present invention will be described below with reference to FIGS. 1-5A. The selvedge yarn shedding device of this preferred embodiment is located in the loom beside each end of the warp heald frames forming the shed of the warp yarns and in front of the warp heald frames. The selvedge yarn shed forming device is used to form a selvedge weave W (see FIG. 2 ) at one end of the fabric.

[0019] As shown in Figure 1, the selvedge yarn shed forming device 10 comprises: the box B that is contained on the base that is used as the support frame of the loom; The driving motor 12 that is fixed on the box B; The sliding body 16 that slides back and forth in the vertical direction; is connected with the driving motor 12 so as to convert the rotation of the driving motor 12 into the reciprocating sliding connecting rod 14 of the sliding body 16; two pairs of selvedge yarn healds connected with the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com