Method for solving polluted environment form coal tar smoke by molding, granulating coal tar under water

A technology that pollutes the environment and coal tar pitch, applied in the direction of curing/crushing processing tar pitch/petroleum pitch/natural pitch, etc., can solve the problem that the worker's operating environment cannot be completely improved, and achieves fewer times, stable and reliable system, and guaranteed safety. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

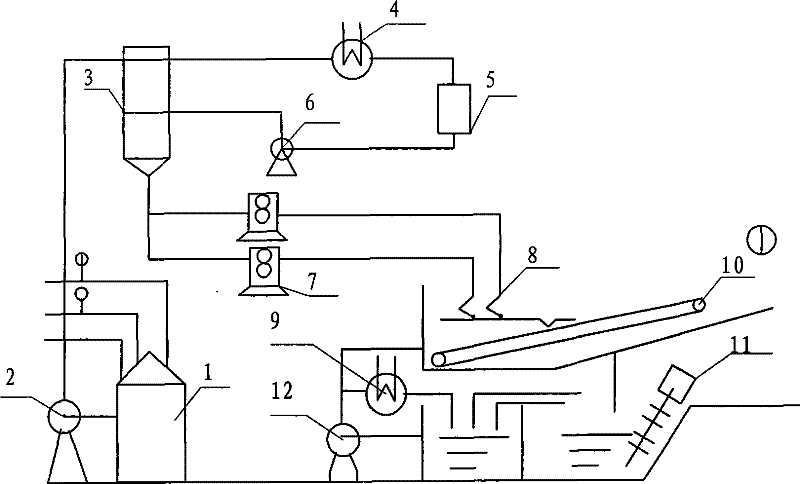

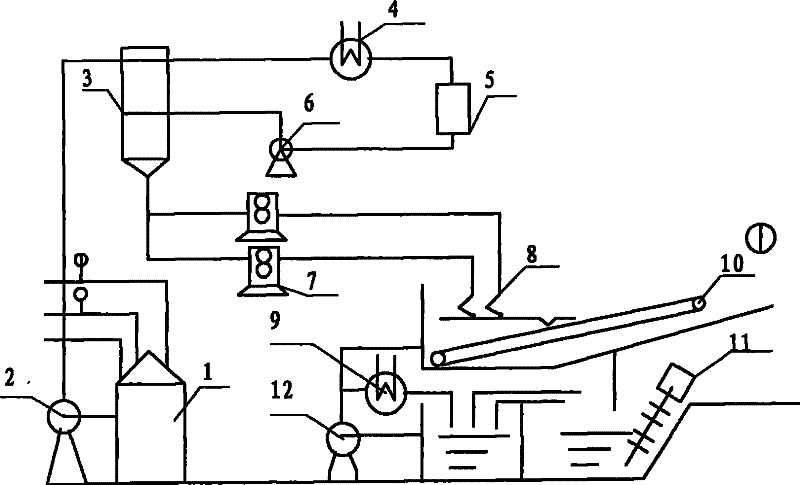

[0018] The detailed description is given below according to the process flow chart.

[0019] 1. Asphalt preparation

[0020] The liquid bitumen above 250°C from the distillation system enters the bitumen product tank 1, and the bitumen in the bitumen product tank 1 is partially fed to the bitumen cooler through the bitumen circulation pump 2 to keep the bitumen liquid level at the bottom of the bitumen cooler constant, and the other part , recycled back to the asphalt product tank 1 for mixing. The temperature in the bitumen product tank 1 is kept above the critical value (ie above 220°C) by the circulation of the hot fluid (such as heat transfer oil) in the internal heating system. The pumped, internal heating system consists of heating pipes mounted on the center bottom and circumference of the asphalt product tank. The pitch product tank 1 realizes the liquid pitch above 250°C from the distillation system, and uses the thermal fluid carrier to cool the coal pitch to 220°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com