Middle shaft power saving and speed increase driving mechanism

A technology of speed-increasing transmission and driven shaft, applied in the direction of transmission, gear transmission, mechanical equipment, etc., can solve the problems of waste, small useful work, and laborious pedaling power, and achieve the effect of improving efficiency and increasing walking distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] best practice

[0012] The best mode for carrying out the present invention will be described below with reference to the drawings.

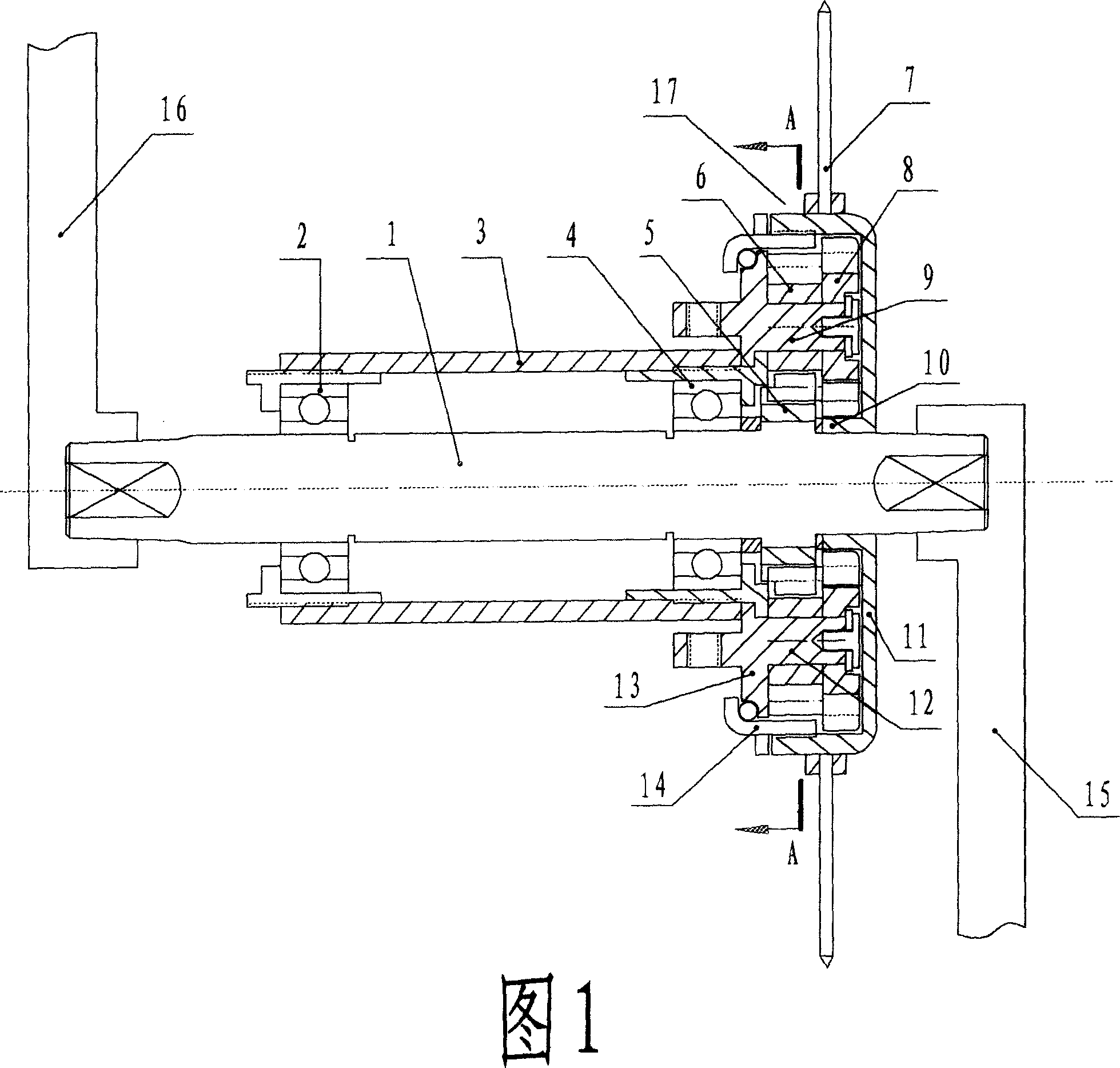

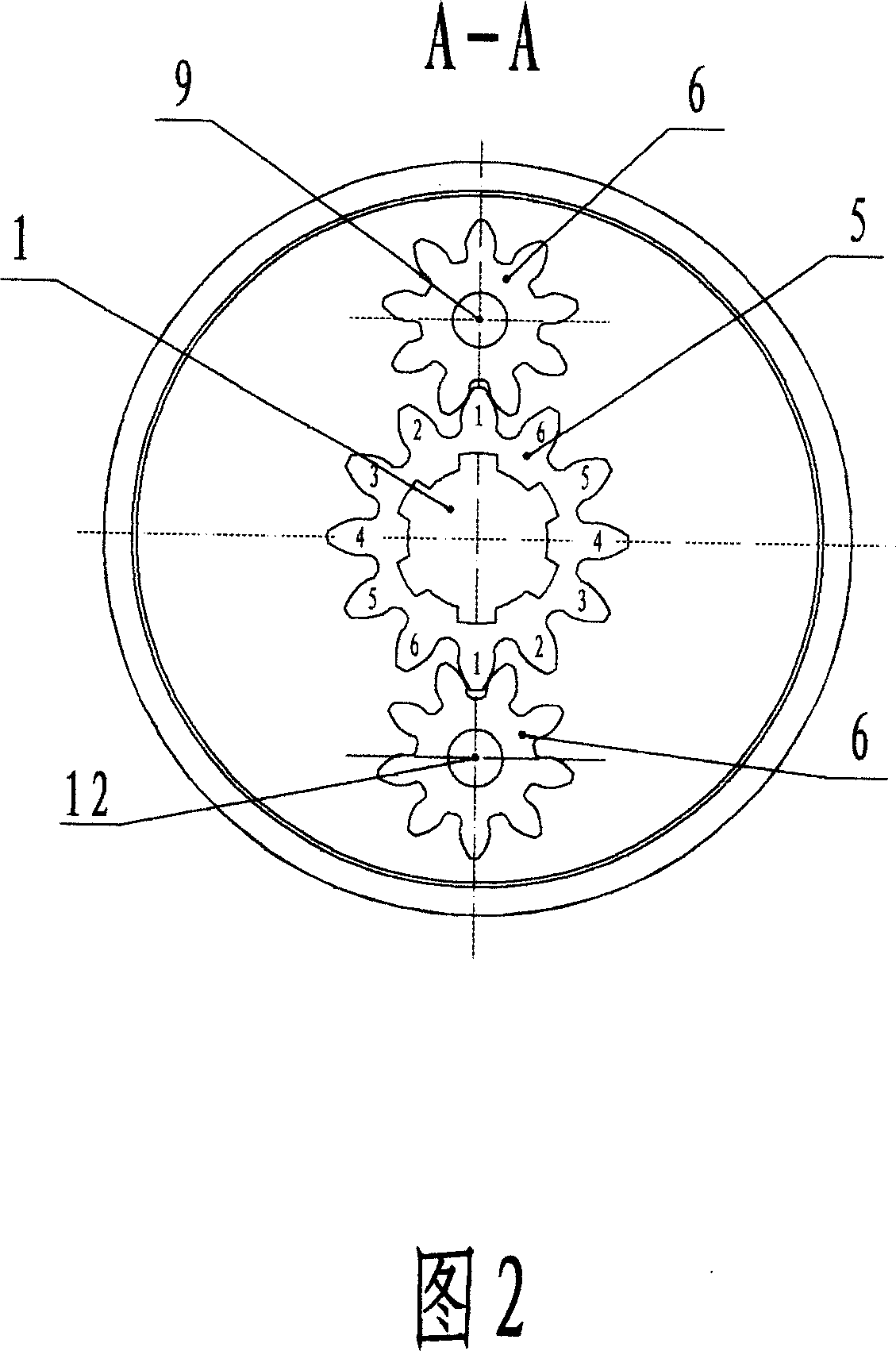

[0013] A central shaft labor-saving speed-up transmission mechanism, comprising a central shaft 1, a bottom bracket 3, a housing 17, a left crank 16, a right crank 15 and a gear plate 7 located at both ends of the central shaft 1, a driven shaft 9 and a driven shaft 12 is located in the housing 17 parallel to the central shaft 1, and the axial direction of the central shaft 1 is sequentially equipped with bearings 2, bearings 4, left gear 5 and right driven gear 10, and the left gear 5 is fixed on the central shaft 1 Above, the right driven gear 10 is hinged on the center shaft 1 and can rotate relative to the shaft, wherein the shapes or angles of the teeth on the left gear 5 are at least partly different, and are all designed according to special requirements; on the driven shaft 9 and the driven shaft 12 are respectively equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com