Electromagnetic valve control circuit and electromagnetic valve control method for water heater

A control method and control circuit technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of gas explosion and gas leakage, and achieve the effect of preventing gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

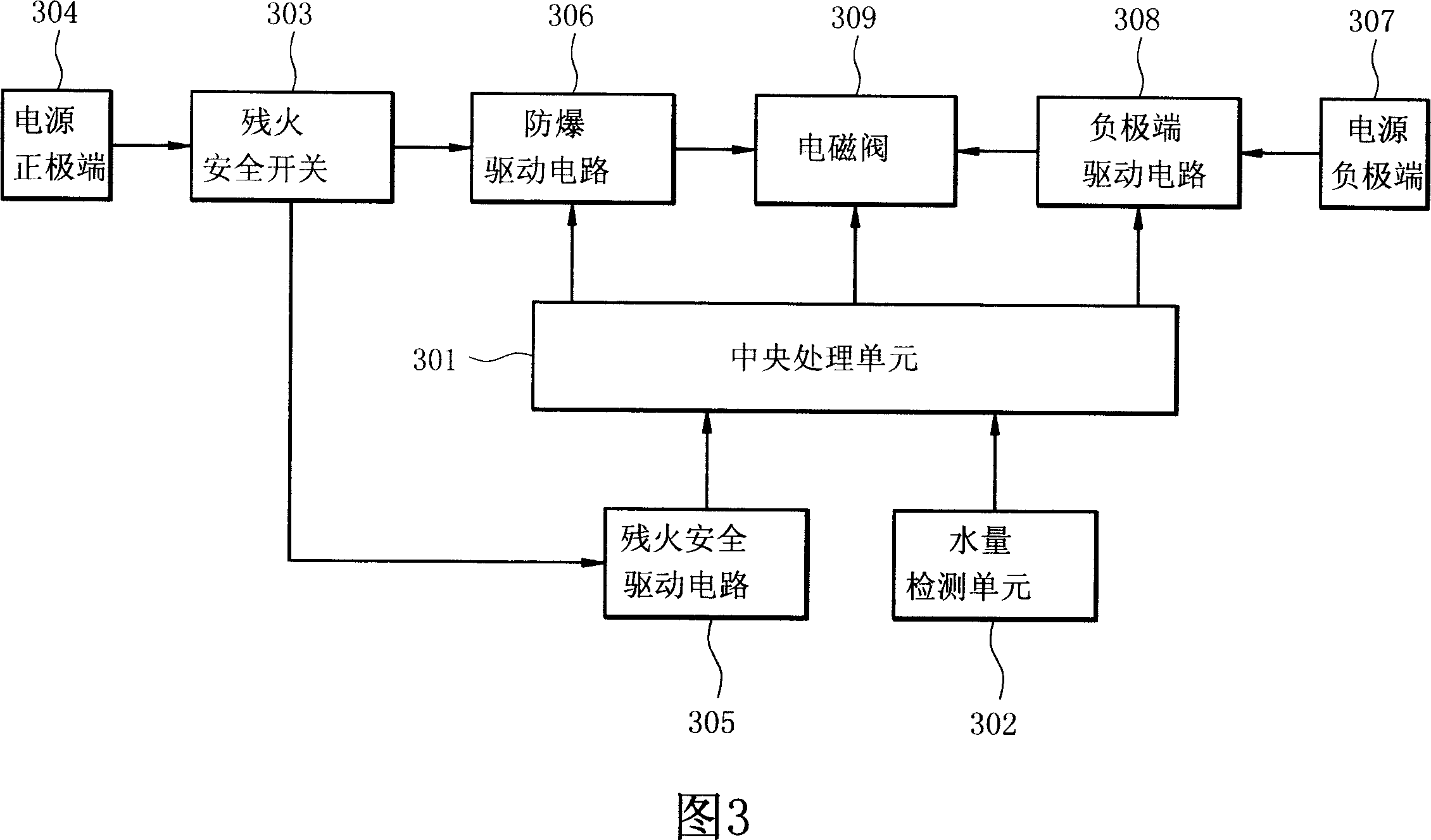

[0029] Please refer to Fig. 3, Fig. 3 is the functional block diagram of the electromagnetic valve control circuit of the present invention, as shown in Fig. A processing unit 301 , an explosion-proof driving circuit 306 , a negative terminal driving circuit 308 and a solenoid valve 309 . Wherein the residual fire safety switch 303 receives the positive power sent by the positive terminal 304 of the power supply, and detects whether there is residual fire in the water heater. Then turn on the residual fire safety switch 303 to output the positive power to the explosion-proof drive circuit 306 and to the residual fire safety drive circuit 305 . The overfire safety driving circuit 305 sends an overfire safety signal to the central processing unit 301 . The water quantity detecting unit 302 is used for detecting the water quantity, and outputs a signal of detecting the water quantity to the central processing unit 301 . After the central processing unit 301 receives the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com