Punching die

A punch and die technology, applied in the direction of perforation tools, manufacturing tools, metal processing equipment, etc., can solve the problem of unclear conditions such as the size deviation to one side, and achieve the effect of reducing the allowable displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

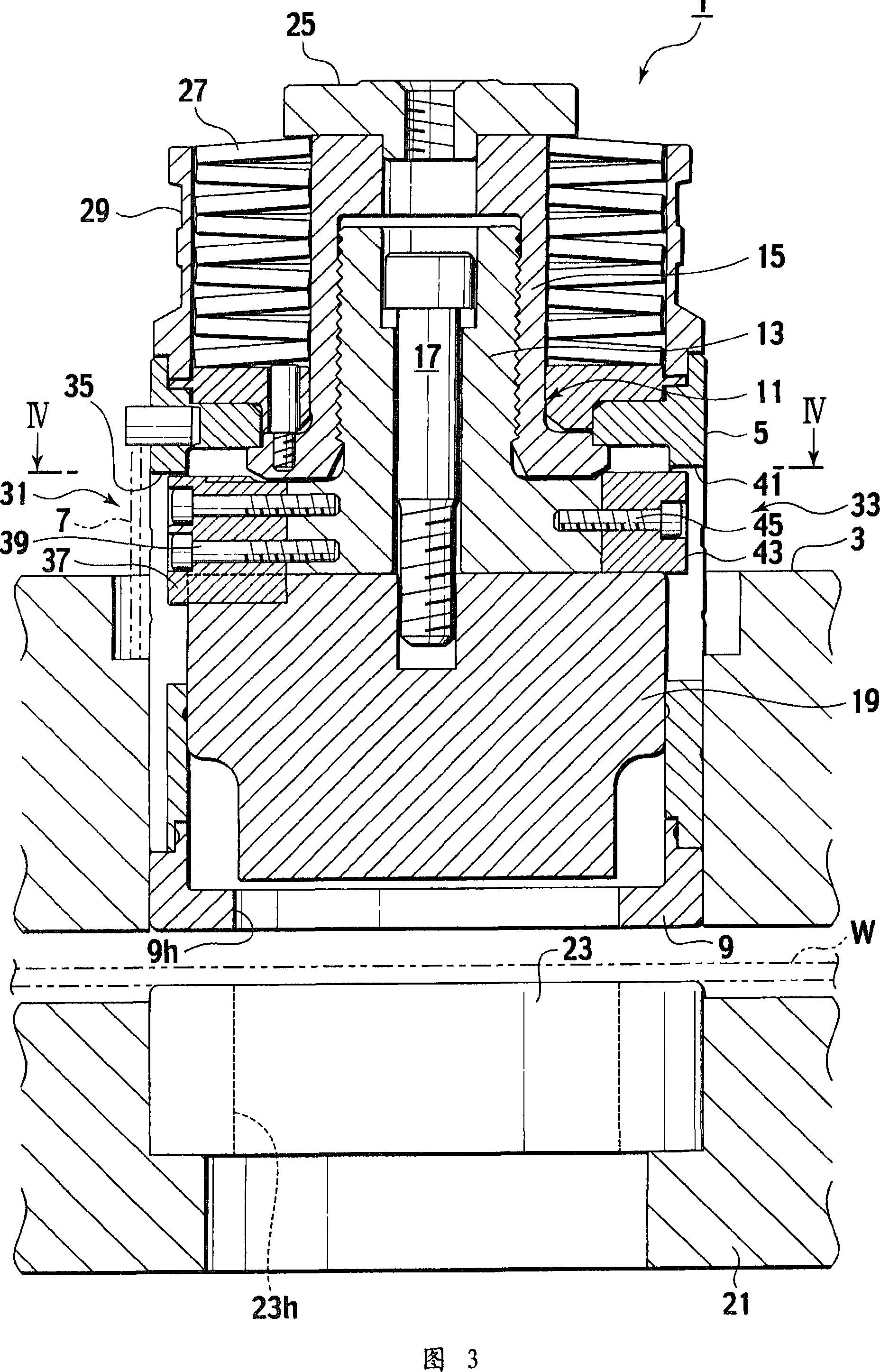

[0040] Next, a preferred embodiment of the present invention will be described with reference to FIGS. 3 to 6. FIG.

[0041] Here, FIG. 3 is a cross-sectional view of the punch die according to the first embodiment of the present invention, and FIG. 4 is a cross-sectional view along line IV-IV of FIG. 3 .

[0042] As shown in FIGS. 3 and 4 , the punch die 1 according to the embodiment of the present invention is held on a punch die holding member 3 of a punch press when it is used for punching a processed part of a plate-shaped workpiece W. The specific structure of the head mold 1 is as follows.

[0043] That is, the punch die 1 is equipped with a cylindrical punch guide cylinder 5, and the punch guide cylinder 5 can be lifted up and down by a plurality of (only one is shown in the figure) springs 7 (in FIG. 4 is held on the punch die holding part 3 so as to move toward the front and back direction of the drawing. In addition, the punch guide cylinder 5 has a stripper plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com