One-dimensional fiber bragg grating vibration sensor with temperature and prestress compensation

A technology of vibration sensor and fiber grating, which is applied in the direction of instruments, scientific instruments, seismic signal receivers, etc., can solve the problem of increasing the volume of the sensor with structural complexity, and achieve the goal of enhancing the ability to resist lateral interference, ensuring directivity, and ensuring repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

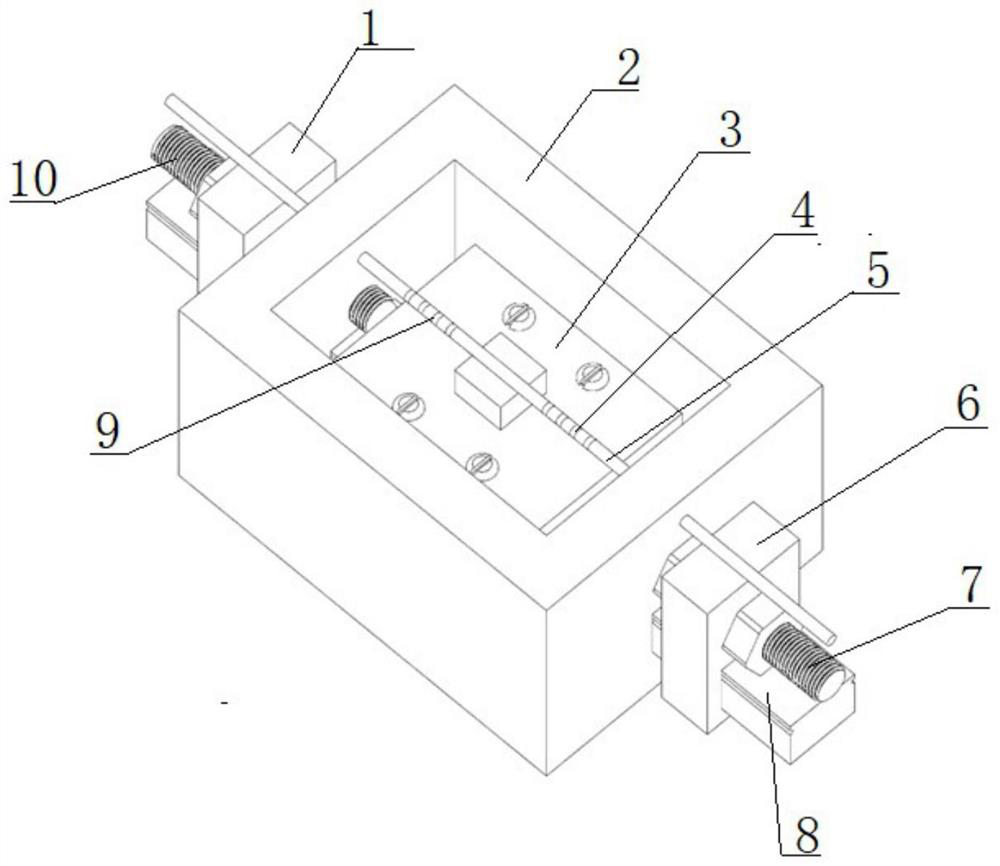

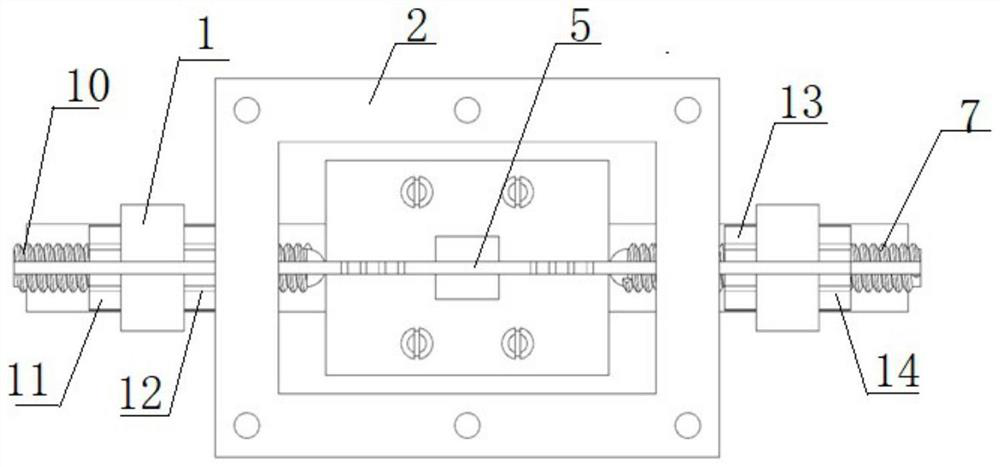

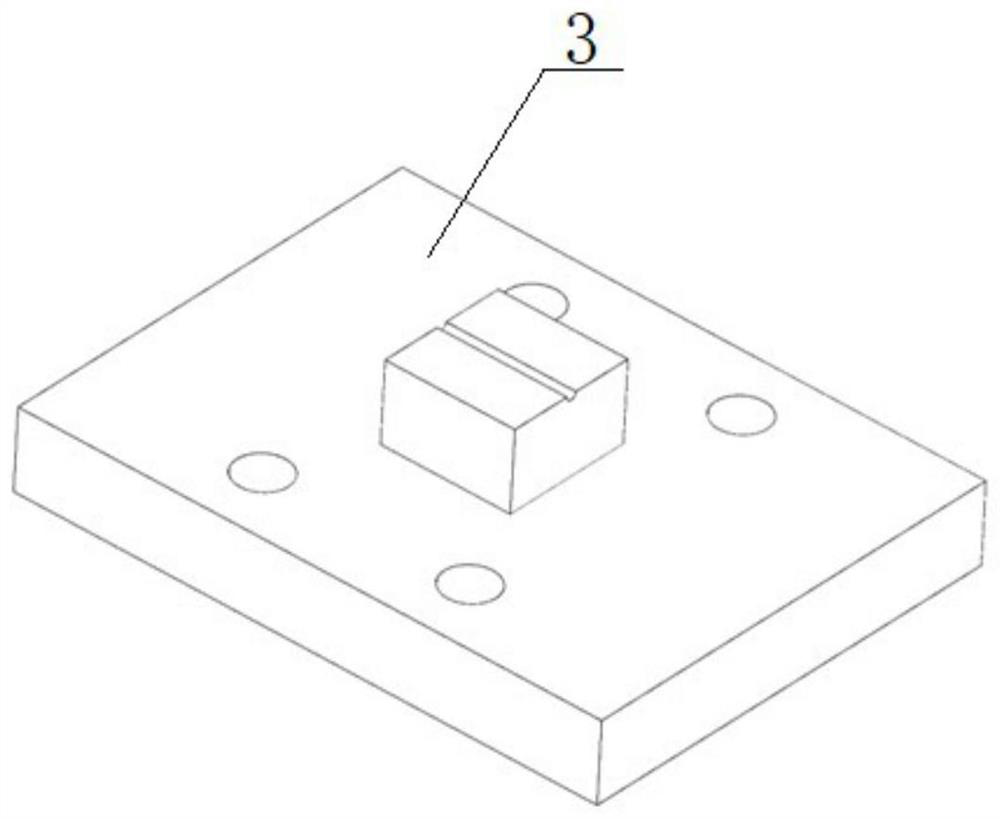

[0043] In the present embodiment, the sensor housing 2 within the middle track 8 is connected by a slider to have a mass block 3, the mass block 3 is provided with an optical fiber support block in the middle of the installation block, the installation block is connected with the optical fiber support block, the mounting block of the mass block 3 is fixed by a thread fastener, the optical fiber support block of mass block 3 is glued with an optical fiber 5, located in the fiber 5 and the mass block 3 bonding position on both sides of the fiber 5 symmetrically inscribed with the same first grating 9 and the second grating 4, the first grating 9 and the second grating 4 are suspended, The center wavelength of the first grating 9 is 1530 nm, the length of the gate region is 5 nm, the center wavelength of the second grating 4 is 1533 nm, and the length of the gate area is 5 nm. The connection relationship between other components and components is the same as in Example 1.

Embodiment 3

[0045] In the present embodiment, the sensor housing 2 within the middle track 8 is connected by a slider to have a mass block 3, the mass block 3 is provided with an optical fiber support block in the middle of the installation block, the installation block is connected with the optical fiber support block, the mounting block of the mass block 3 is fixed by a thread fastener, the optical fiber support block of mass block 3 is glued with an optical fiber 5, located in the fiber 5 and the mass block 3 bonding position on both sides of the fiber 5 symmetrically inscribed with the same first grating 9 and the second grating 4, the first grating 9 and the second grating 4 are suspended, The center wavelength of the first grating 9 is 1565 nm, the length of the gate area is 5 nm, the center wavelength of the second grating 4 is 1571 nm, and the length of the gate area is 5 nm. The connection relationship between other components and components is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com