Track slab precision adjustment measurement system and adjusting measuring method

A technology of measurement system and track plate, which is applied in the direction of track, measuring instrument, track maintenance, etc., can solve the problems of difficulty in keeping the height consistent, increasing the probability of error, medium precision and difficulty in obtaining accurate values for the height of the prism, etc., and achieve a good market Foreground, high-precision measurement of the effect of installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

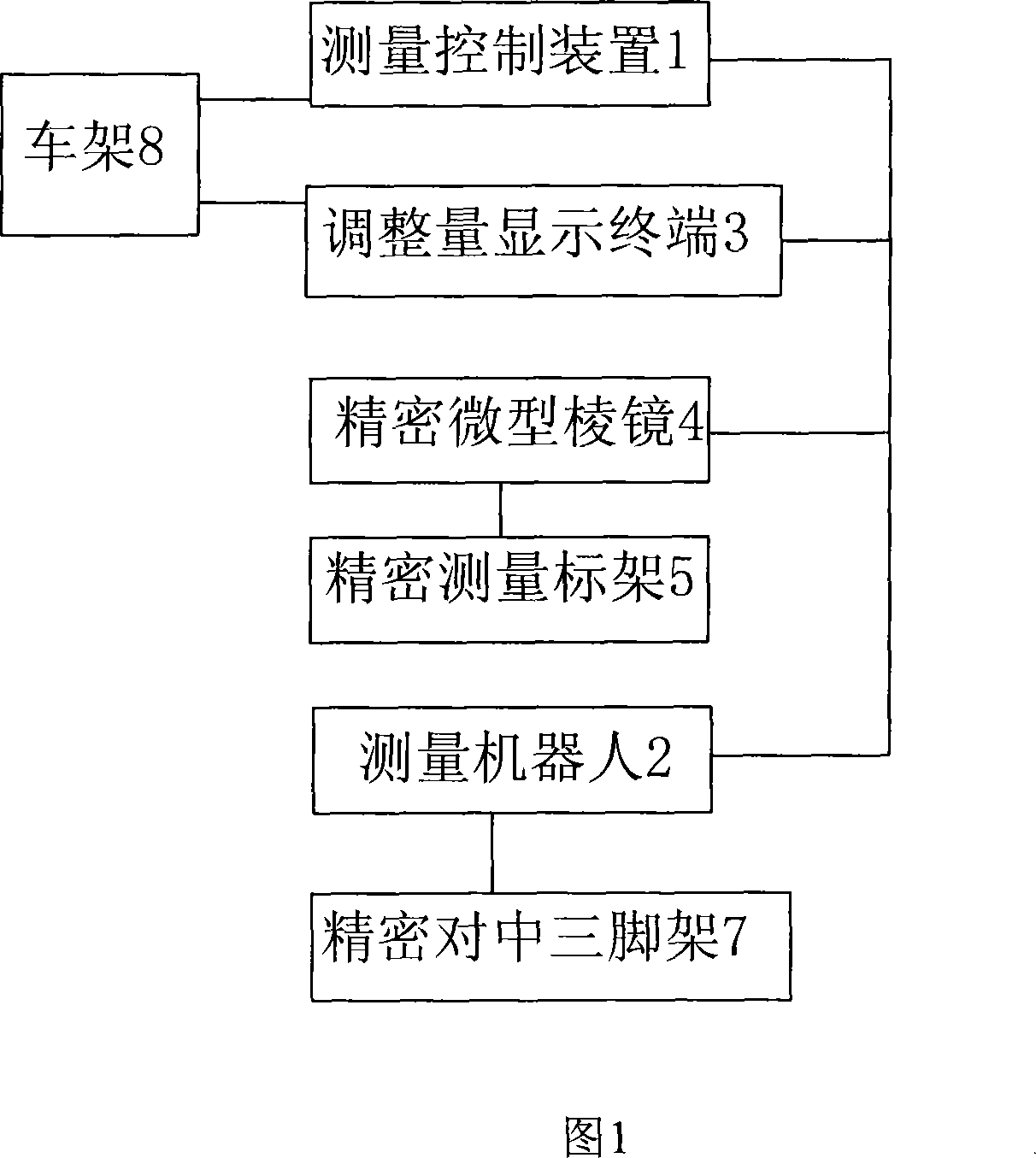

Method used

Image

Examples

Embodiment

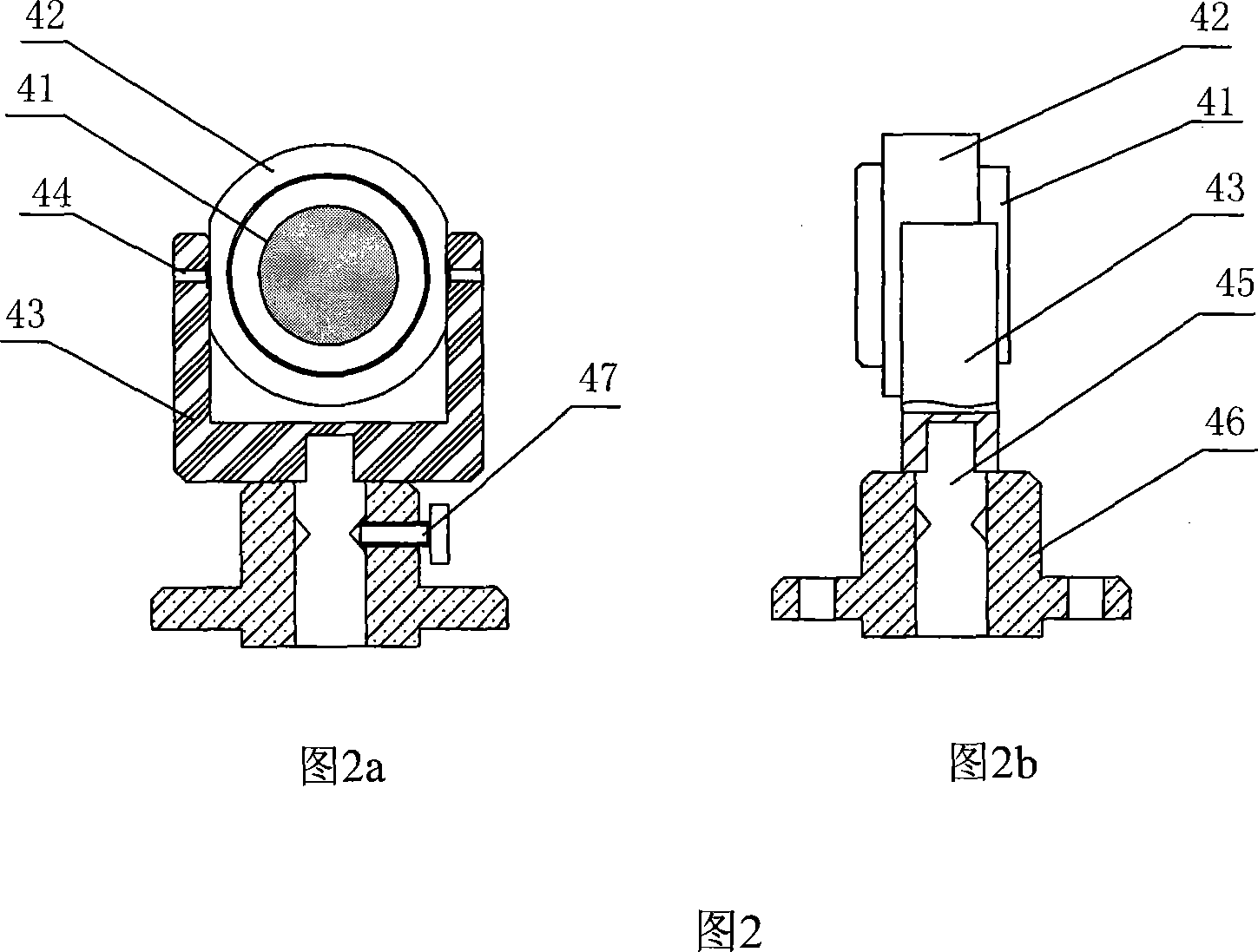

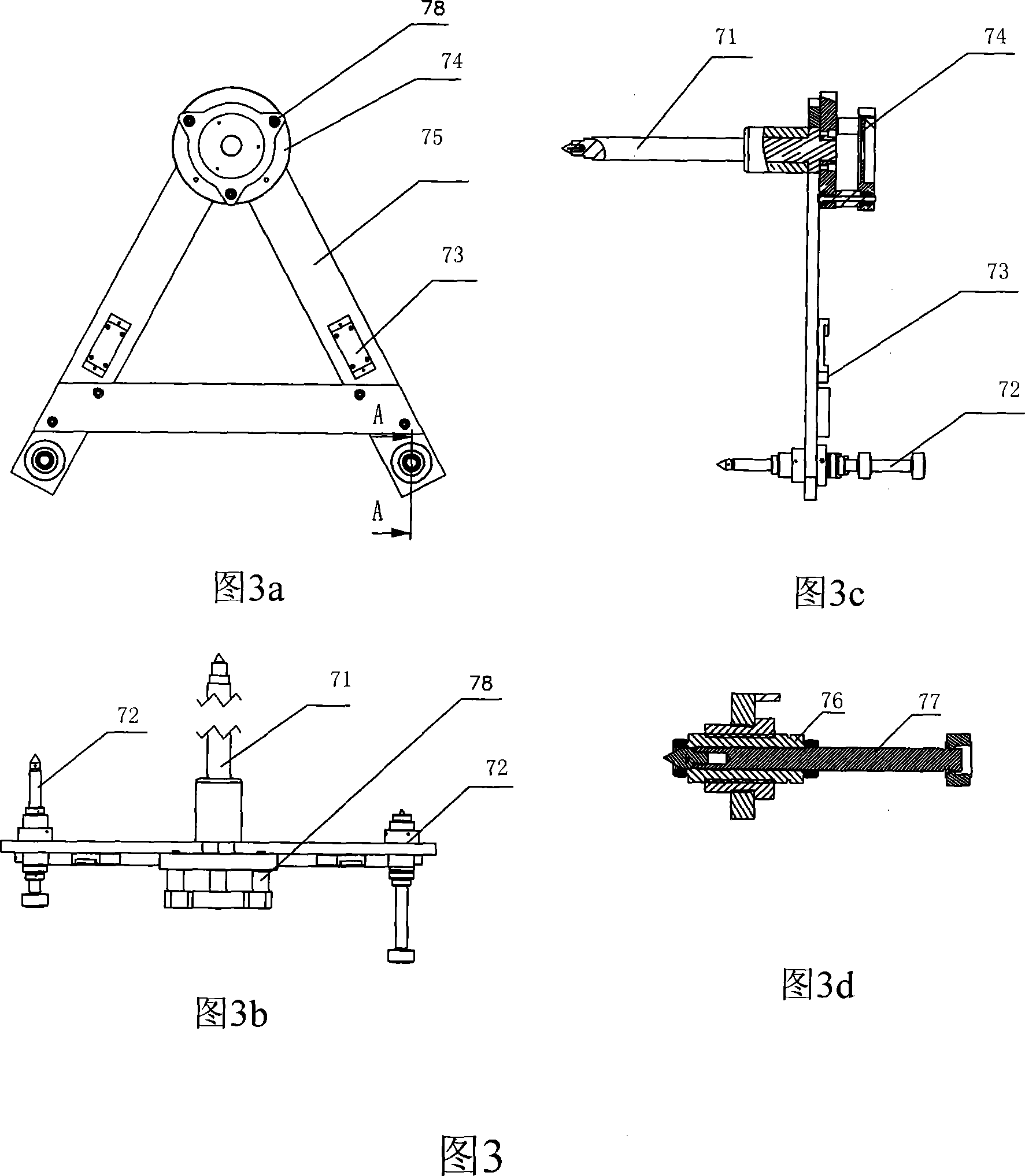

[0020] The processed track slab is composed of 10 pairs of rail bearing platforms, and its number is shown in Figure 5. After being transported from the factory to the laying site, the track slab is placed on the laying position using a crane and rough adjustment equipment. No. 1 precision measurement frame 5 is placed between the No. 1 rail supports, No. 1 inclination sensor is installed on No. 1 precision measurement frame 5, and No. 2 precision measurement frame 5 is placed between No. 6 and No. 16 rail supports. No. 2 tilt sensor is installed on No. 2 precision measurement frame 5, No. 3 precision measurement frame 5 is placed between No. , the track slab is prefabricated with reinforced concrete, and the inclination sensor on the No. 1 precision measuring frame can reflect the inclination state of the whole track slab, but considering that the track slab has a certain length, there may be a certain deflection in the middle, so in An inclination sensor is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com