Operating method of an embroidering machine

An operation method and embroidery machine technology, applied in the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problems of reducing productivity and difficulty in realizing automation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

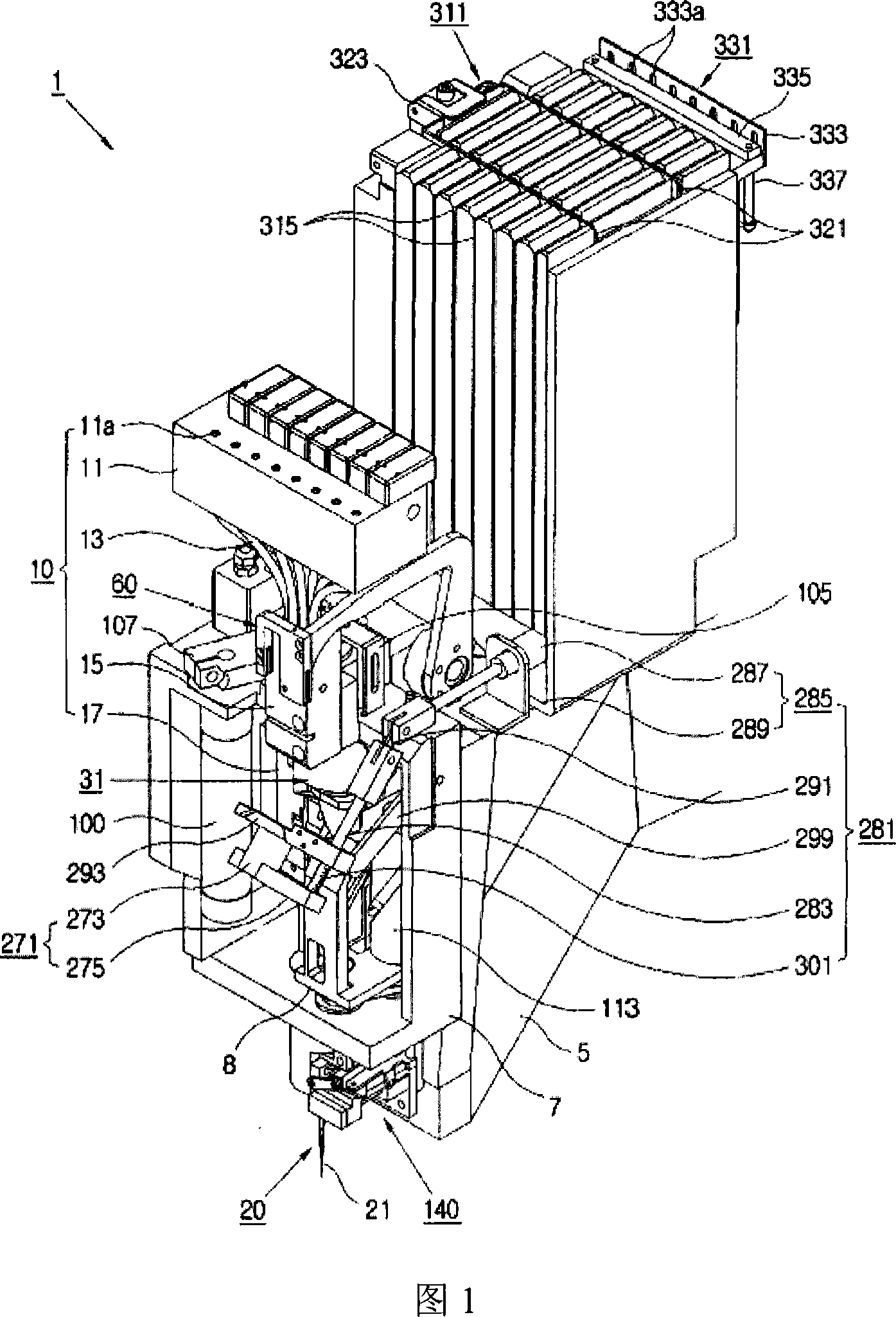

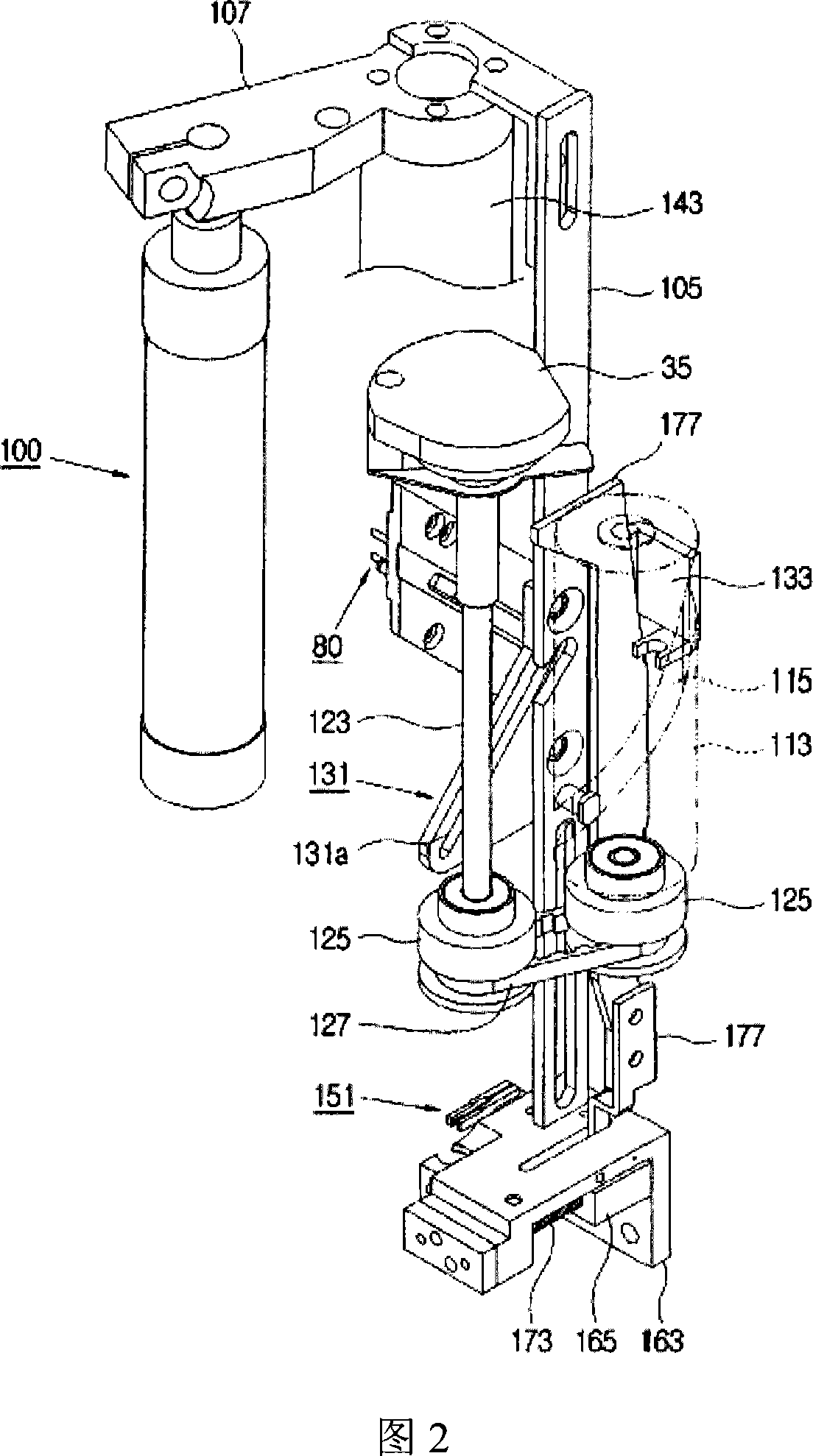

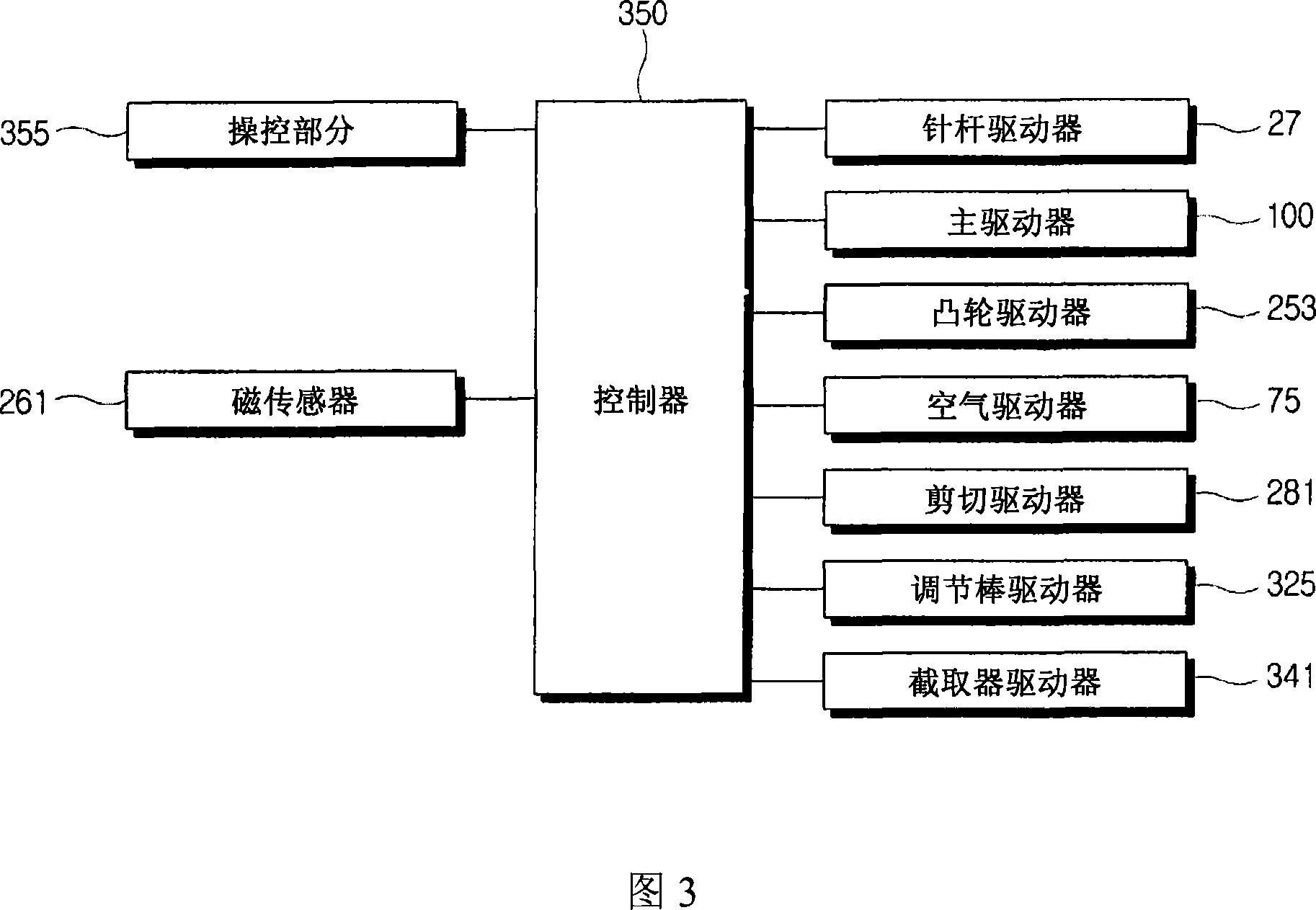

[0035] As shown in FIGS. 1 to 3 , an embroidery machine 1 according to the present invention includes: a mounting frame 5 ; a machine head 7 arranged in front of the mounting frame 5 ; a thread feeder 10 mounted to the machine head 7 and supply one upper thread selected from a plurality of upper threads on a plurality of thread spools corresponding to a plurality of colors to the needle 21; a needle working unit 20 having a needle 21 threaded with the upper thread 3 , and perform the sewing operation of the needle 21; the thread supply unit, which supplies the upper thread 3 from the thread feeder 10 to the needle working unit 20, and passes the upper thread 3 through the needle 21; the thread breakage sensor 240, the thread break sensor 240 is used to detect whether the upper thread 3 moving along the thread conveying path is broken; and the cutting unit 270, the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com