A device for loading,unloading or hoisting cargo platform

A lifting device and platform technology, which is applied in the field of loading and unloading or lifting cargo platform devices, and can solve the problems of reducing the safety and reliability of loading and unloading locking safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

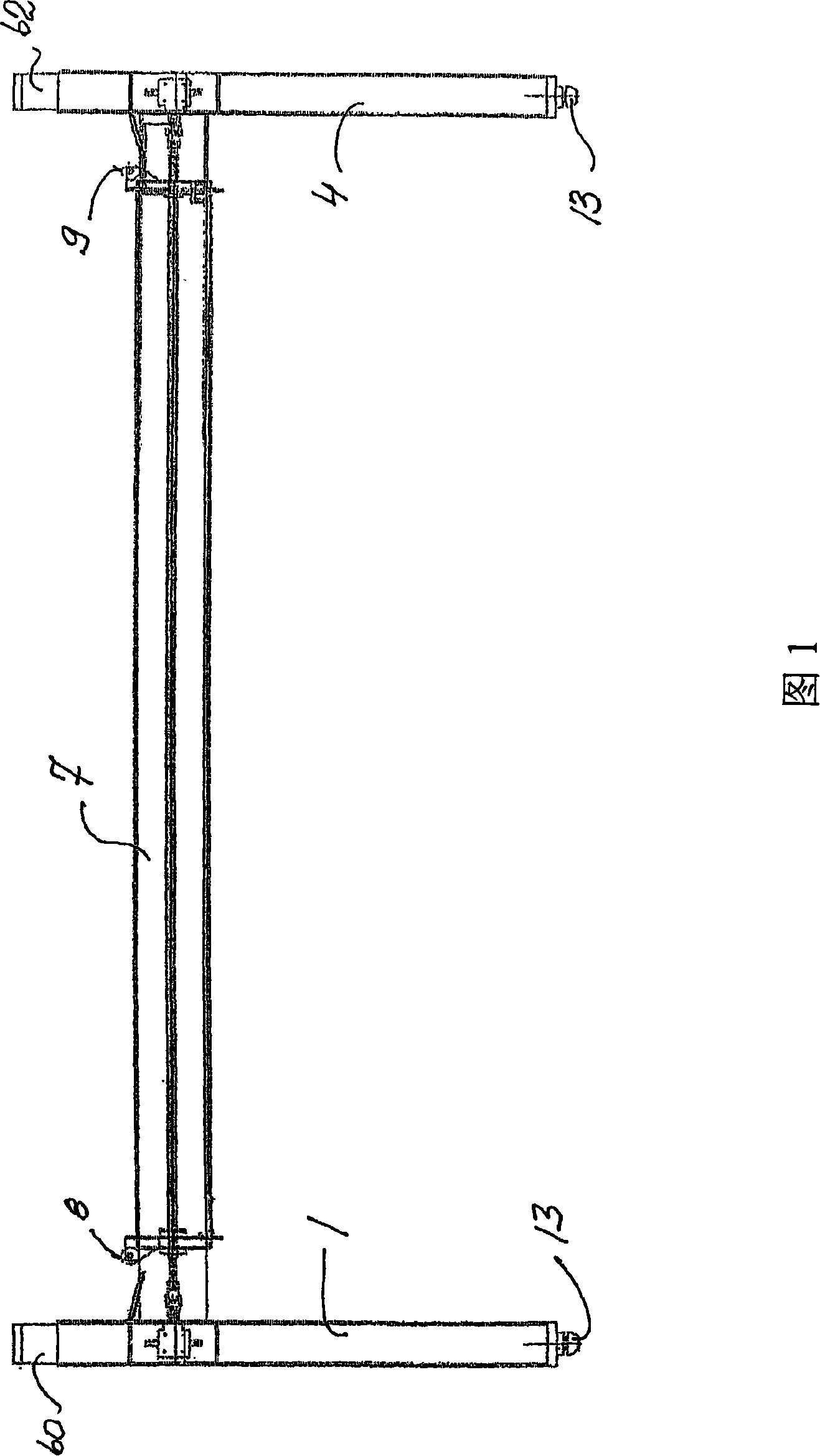

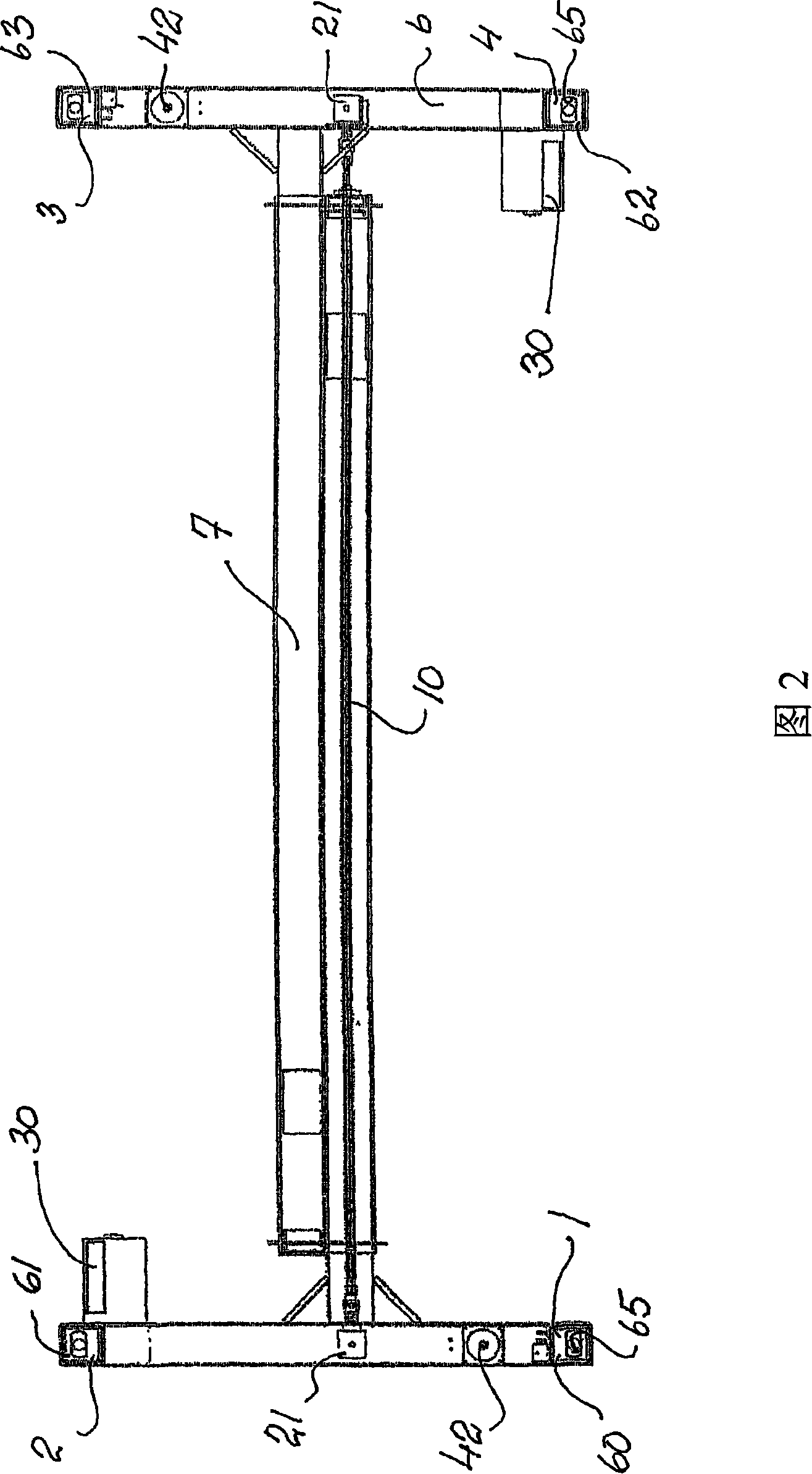

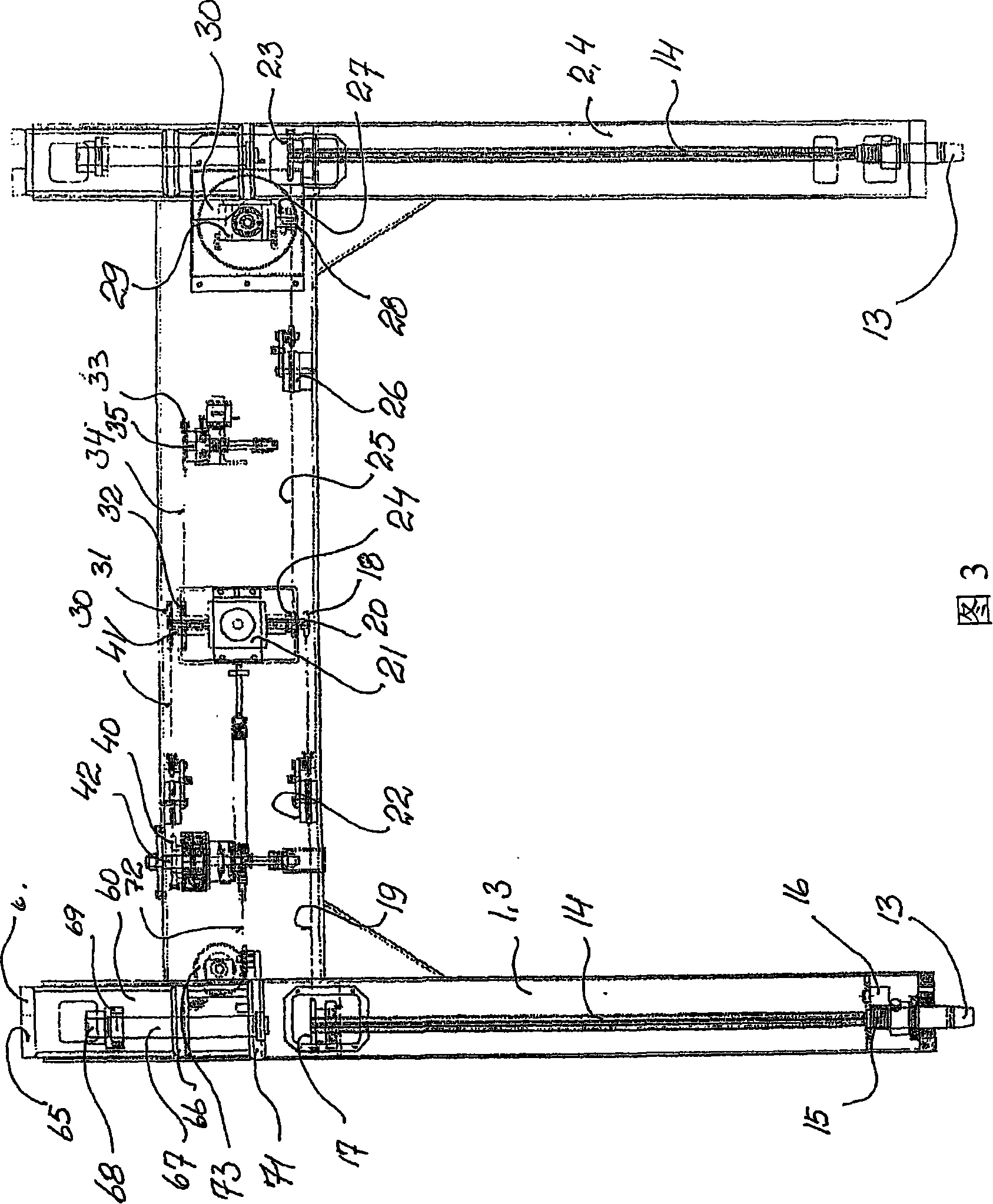

[0015] The following will combine Figure 1-3 Embodiments of the device of the invention shown in the figures are described in detail by the intermediate or extension shown in the drawings, which are also referred to as middle yokes, frames and the like. The same reference numbers in different figures refer to the same components.

[0016] The middle piece or extension has four legs 1-4 which are mounted on the ends of the end beams 5,6. The end beams 5, 6 are connected to each other by web beams 7 which may be fixed or as in the shown embodiment telescopic and which consist of 2 beams next to each other. The web girder 7 is easily telescopic by the rollers 8 and 9 . The end beams 5 and 6 are connected to each other by telescopic shafts 10 . The feet 1-4, the end beams 5, 6 and the web beam 7 consist of tubular beams, for example having a square tubular configuration.

[0017] Figure 4 The end beams 5, 6 are specified. The diagonally arranged feet 1, 3 are provided in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com