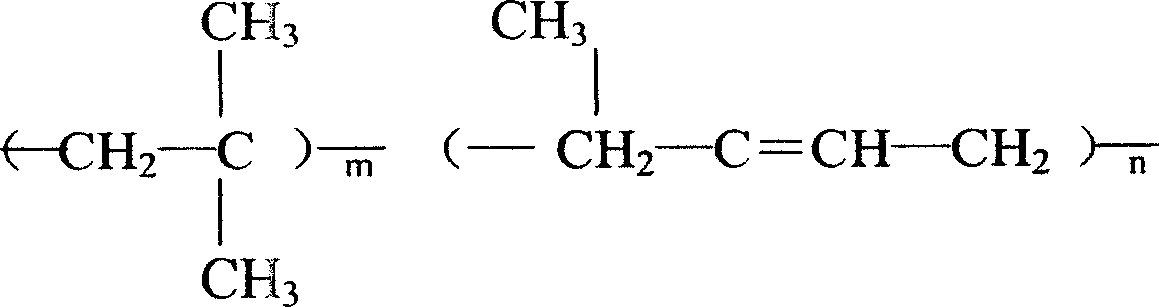

Composition of oil resisting butyl rubber

A technology of butyl rubber and composition, applied in the field of oil-resistant butyl rubber composition, can solve the problem of lack of oil resistance, etc., and achieve the effect of facilitating popularization and application and broadening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] Preparation of masterbatch for blending and blending

[0017] For the convenience of showing the effect of the present invention, at first prepare the masterbatch based on butyl rubber and nitrile rubber respectively by the formula shown in table 1, the butyl rubber used is the butyl 268 that Beijing Yanshan Chemical Company produces, and this The masterbatch is called masterbatch A, and the nitrile rubbers used are nitrile-18, nitrile-26 and nitrile-40, respectively, and are named in turn: masterbatch B, masterbatch C and masterbatch D.

[0018] Table 1

[0019] component name

[0020] coupling agent

[0021] The components listed in Table 1 are mixed in an internal mixer, and the debinding temperature is controlled at 120-130°C.

Embodiment 1~3 and comparative example 1~9

[0023] The masterbatches A, B, C, and D prepared from the components listed in Table 1 are mixed and blended in different ways as shown in Table 2 and Table 3, and then mixed into different vulcanization systems. The dosage is listed in Table 2. 160 ℃ × 50min vulcanization to make a standard test piece for testing, the test results obtained are summarized in Table 2 and Table 3.

[0024] Table 2

[0025]

Example

1

Example

2

Example

3

comparative example

1

comparative example

2

comparative example

3

Compare

example

4

Blending

Compare

(weight / weight

quantity)

Masterbatch A / master

Glue C

=80 / 20

Masterbatch A / master

Glue C

=80 / 15

Masterbatch A /

Masterbatch C

=75 / 25

Masterbatch A / master

Glue C

=80 / 20 (Note

1)

Masterbatch A /

Masterbatch C

=70 / 30

Masterbatch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com