Synthronous device of roller in ring spinning frame short vehicle

A technology of synchronous device and spinning frame, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve problems such as end breakage, affecting yarn quality, and yarn thickness, and achieves convenient adjustment, The effect of reducing labor intensity and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

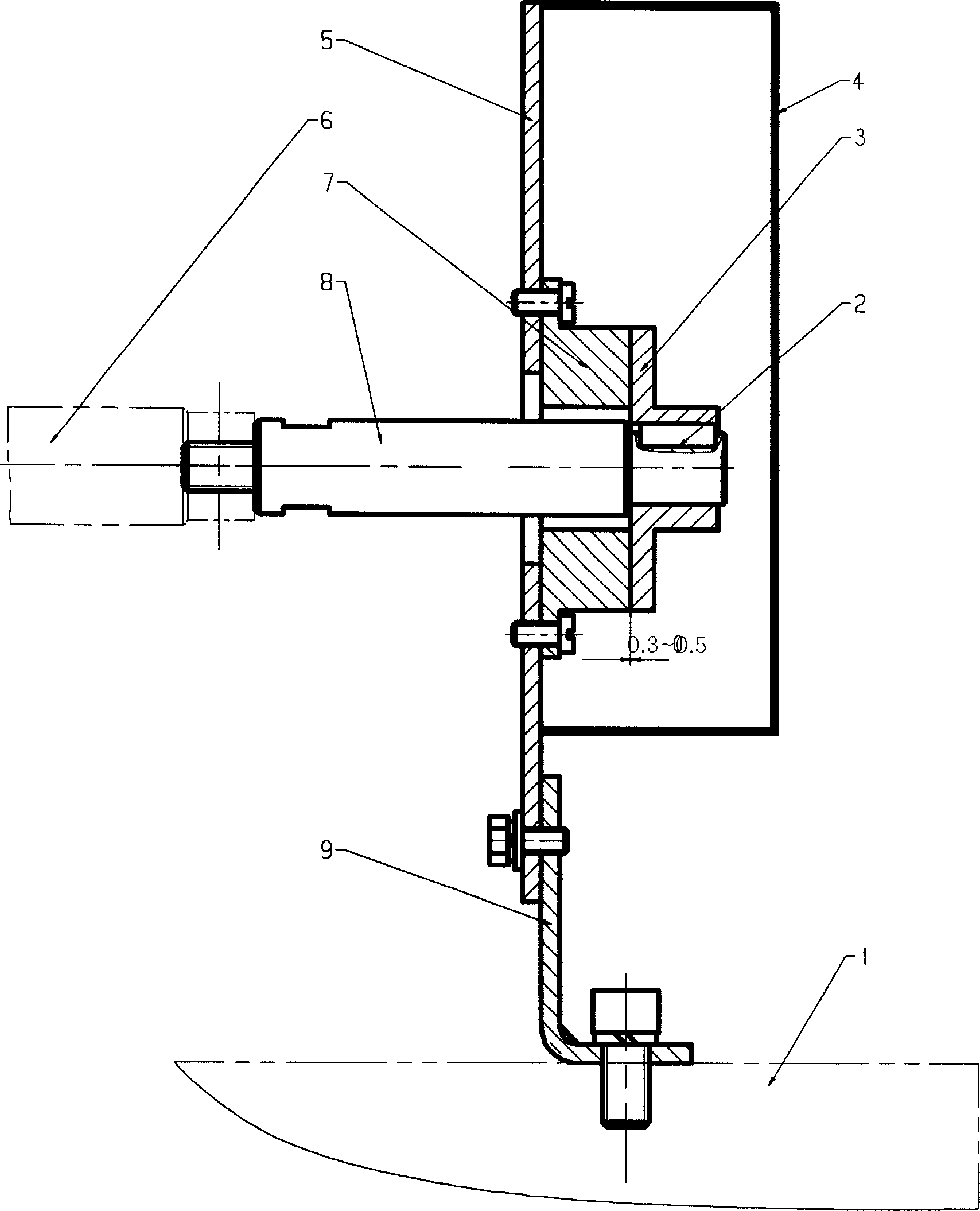

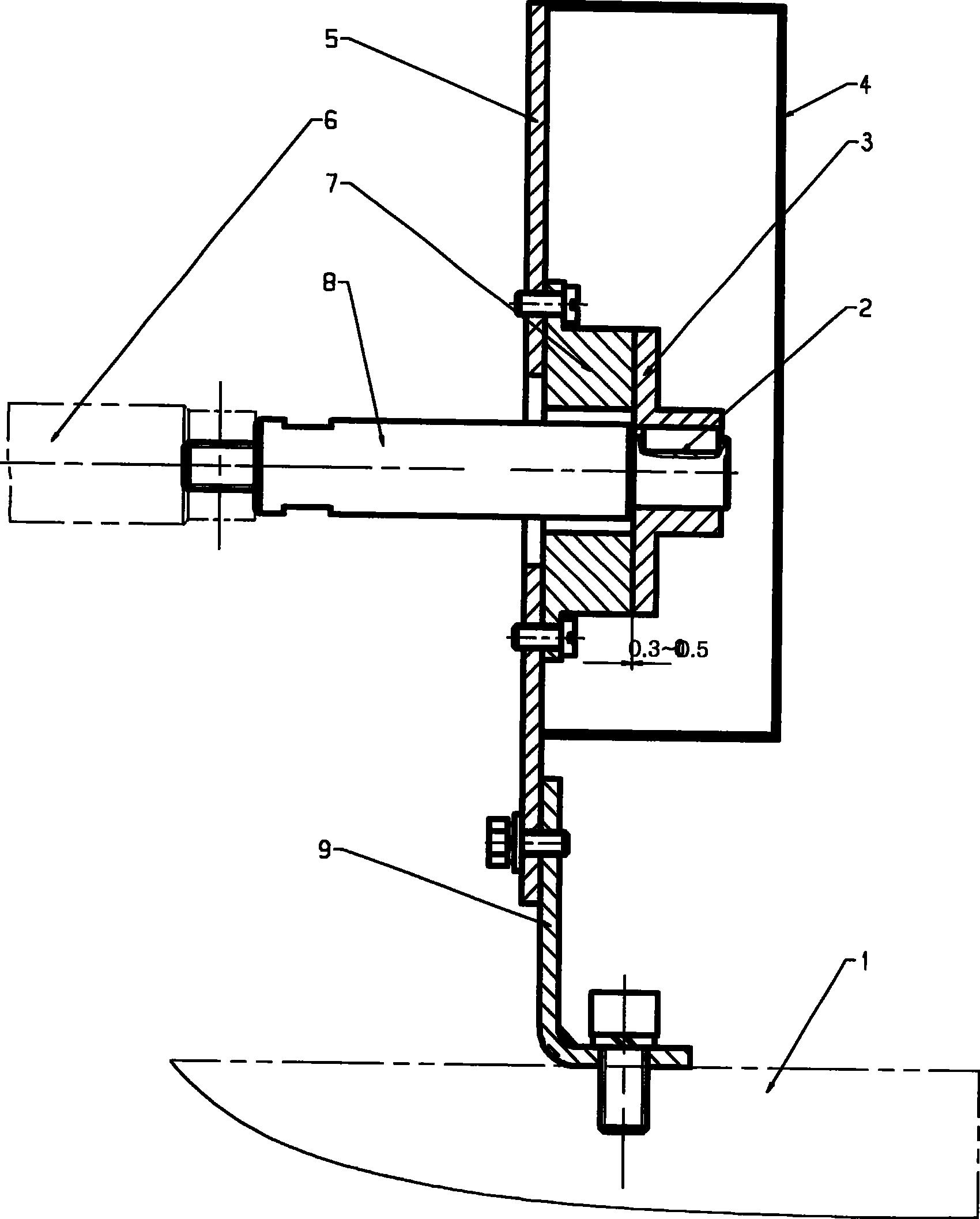

[0008] A synchronizing device for rollers in the short car of ring spinning frame, which includes machine beam 1, base 9, brake seat 5, static plate 7 of electromagnetic brake, shaft 8, key 2, moving plate 3 of electromagnetic brake and casing 4 . The base 9 is connected to the machine beam 1, the brake seat 5 is connected to the base 9, the static plate 7 of the electromagnetic brake is connected to the brake seat 5, the brake seat 5 is provided with a cover, and the moving plate 3 of the electromagnetic brake is connected to the shaft 8 through the key 2 Connection, the shaft 8 is connected with the middle roller tail section 6, and there is a gap of 0.3-0.5 mm between the moving plate 3 of the electromagnetic brake and the static plate 7 of the electromagnetic brake. The synchronizing device of the middle roller is located at the rear of the short car of the ring spinning frame.

[0009] Working method: When in use, adjust the distance between the friction plate on the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com