Stretching control method of the stretching unit of a spinning machine and a spinning machine

A technology of textile machinery and control methods, used in spinning machines, drafting equipment, textiles and papermaking, etc., can solve problems such as low optimal value of fiber sliver quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

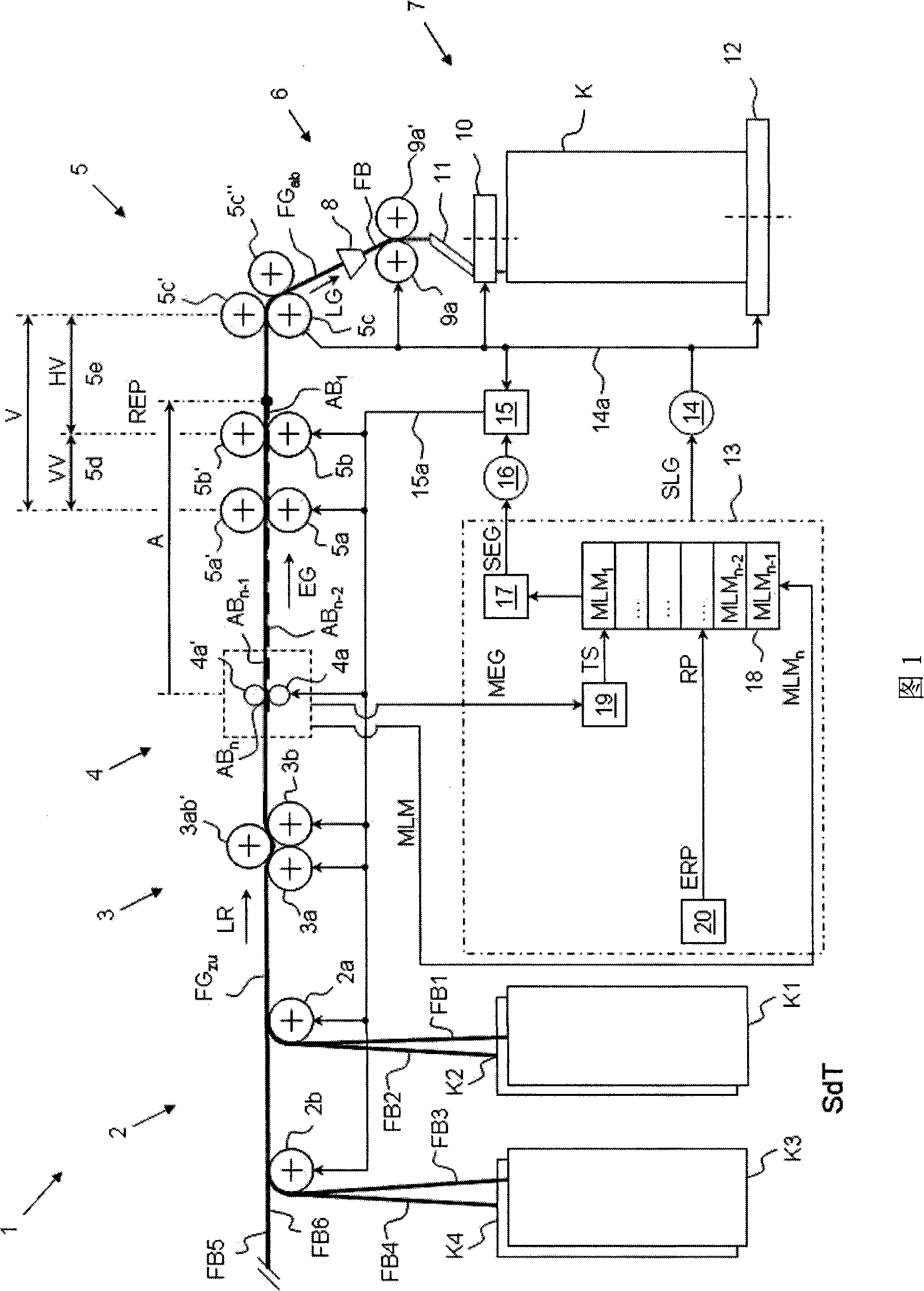

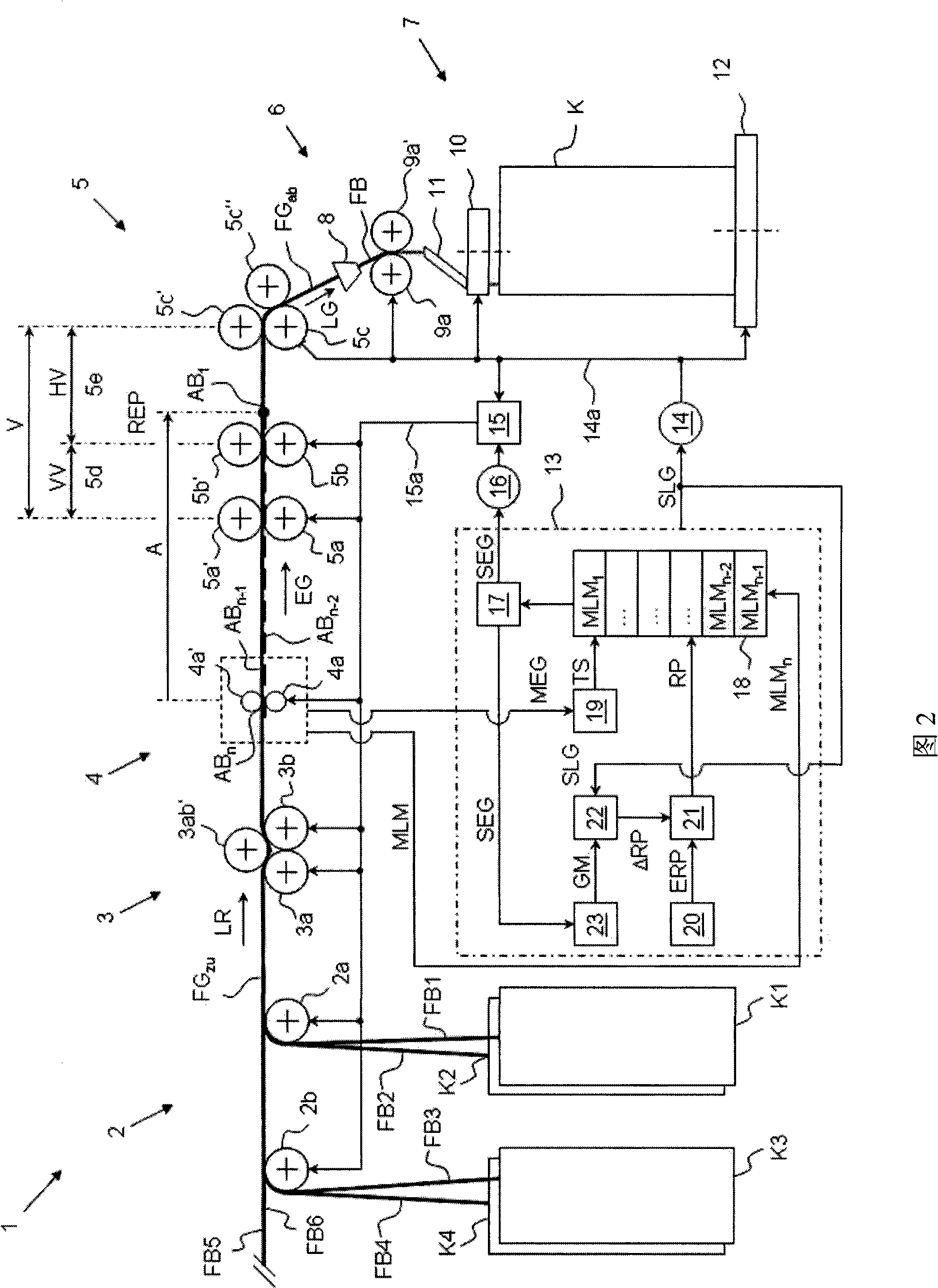

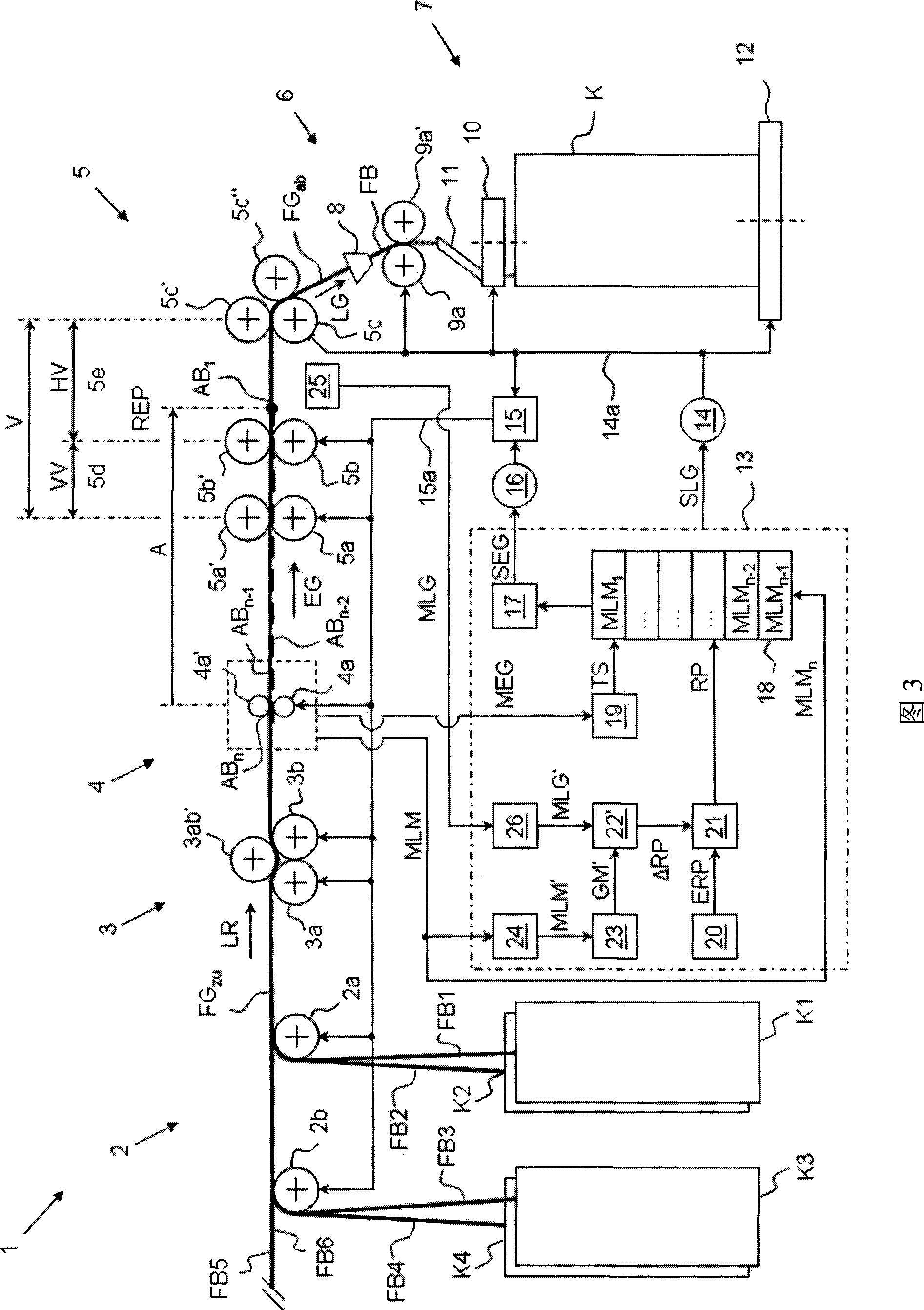

[0032] figure 1 is a schematic side view of a textile preparation machine 1 such as a draw frame 1 . The fiber strips FB1, FB2, FB3, FB4, FB5, FB6 located at the front of the draw frame 1 move along the direction of movement LR, on the feed stand 2 (feed stand), feed roller unit 3, feed sensor unit 4, draft System 5, exit guide 6 and sliver storage 7.

[0033] The only schematically shown guide table 2 comprises a first guide table roller 2a arranged in such a way that the first fiber strip FB1 located at the front of the machine can be drawn starting from the can K1 provided on the draw frame 1, At the same time the second fiber strand FB2 can be drawn starting from the can K2 in the offset position. Also included is a second guide table roller 2b for drafting a third fiber strand FB3 from a third drum K3 and a fourth fiber strand FB4 from a fourth drum K4. The fifth fiber strip FB5 and the sixth fiber strip FB6 are also drafted from other cans (not shown) by other guide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com