Curable fluorine-containing coating composition

A technology of fluorine-containing coatings and compositions, applied in the direction of coating, etc., can solve problems such as insufficient curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

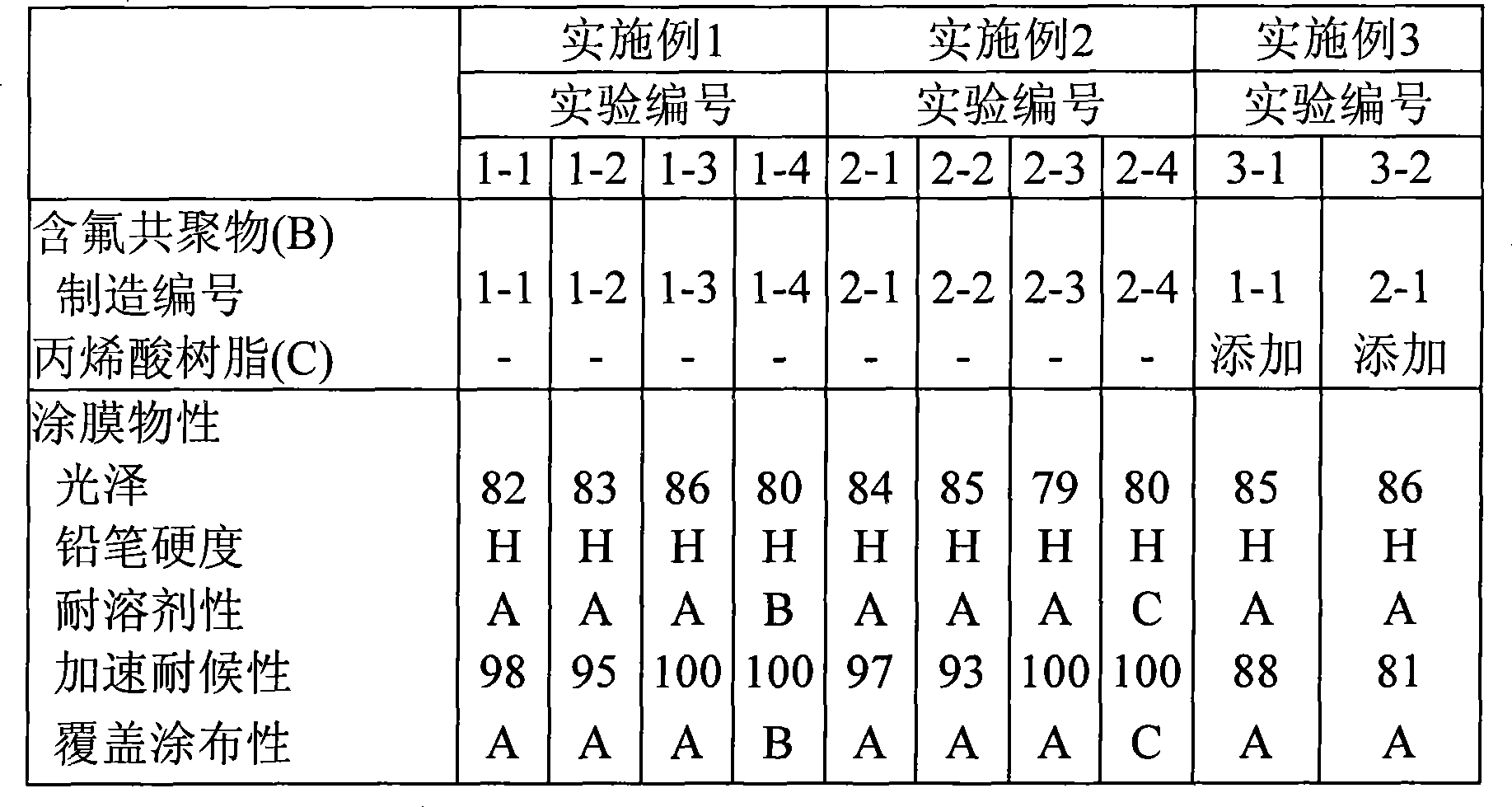

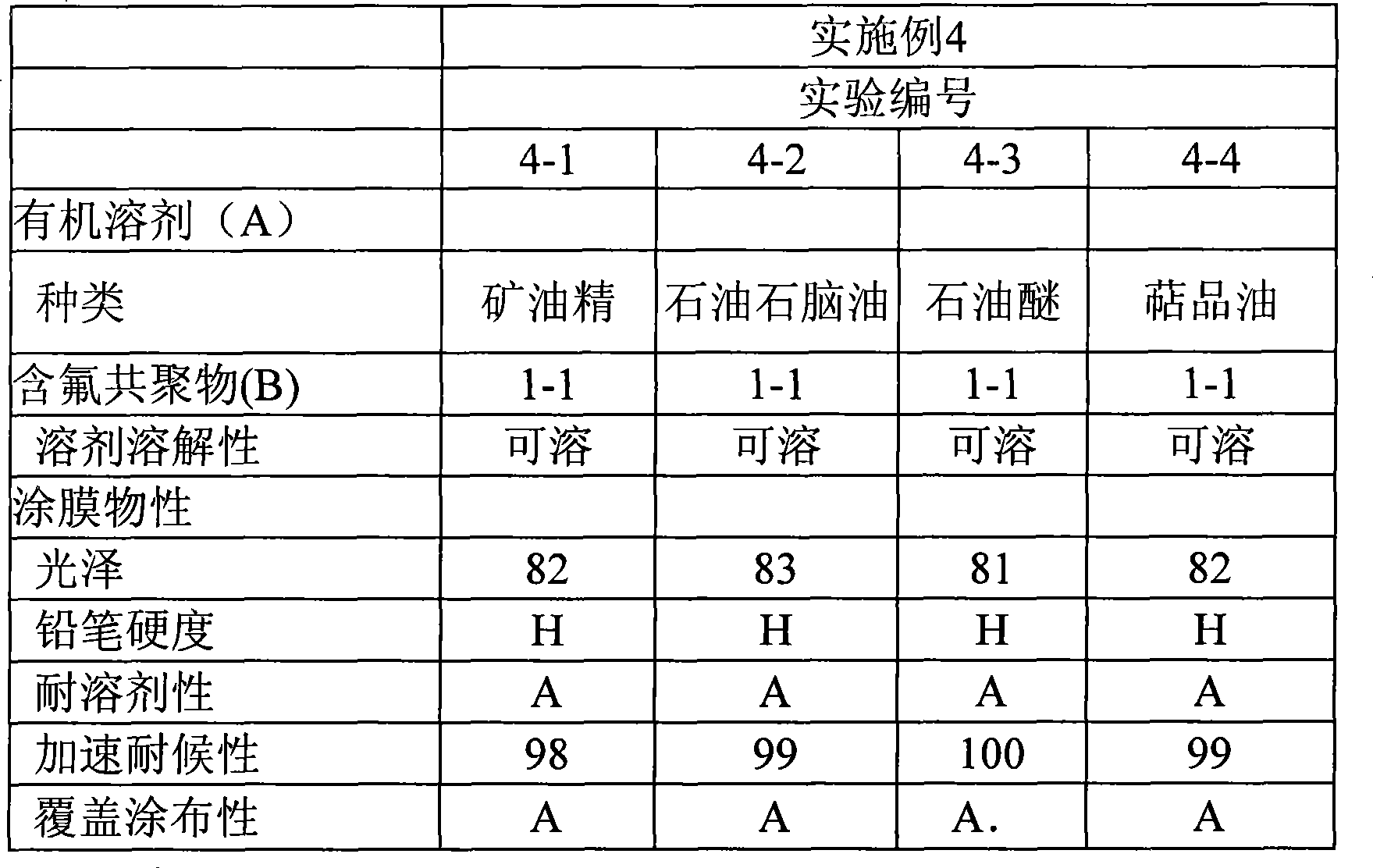

Examples

preparation example Construction

[0047] The preparation of the curable fluorine-containing coating composition of the present invention can be carried out by a conventional method, and can obtain excellent coating properties on metals such as automobiles, airplanes, ships, trams, etc., plastics, concrete, etc. coating composition.

[0048] As the coating method, conventionally known methods can be used, for example, brushes, rollers, sprayers, airless sprayers, flow coaters, roll coaters, spin coaters, etc. can be used to coat various substrates. .

Embodiment

[0050] The present invention will be described more specifically with reference to examples below, but the present invention is not limited to these examples.

[0051] Measuring methods used in this specification other than those described above are as follows.

[0052] (NMR analysis)

[0053] NMR measurement device: manufactured by BRUKER

[0054] 1 H-NMR measurement conditions: 300MHz (tetramethylsilane = 0ppm)

[0055] 19 F-NMR measurement conditions: 282MHz (trichlorofluoromethane = 0ppm)

[0056] (Elemental analysis)

[0057] Measuring device: CHN CORDER produced by J-Science and Ionalyzer901 produced by Orio Research

[0058] (hydroxyl value and acid value)

[0059] Calculations were performed based on compositions obtained by NMR and elemental analysis.

[0060] (number average molecular weight)

[0061] Measuring device: GPC (model HLC-8020) manufactured by Tosoh Co., Ltd.

[0062] Determination conditions: use 3 TSKgel: GMHXL, 1 G2500HXL, 1 GRCXL-L as chroma...

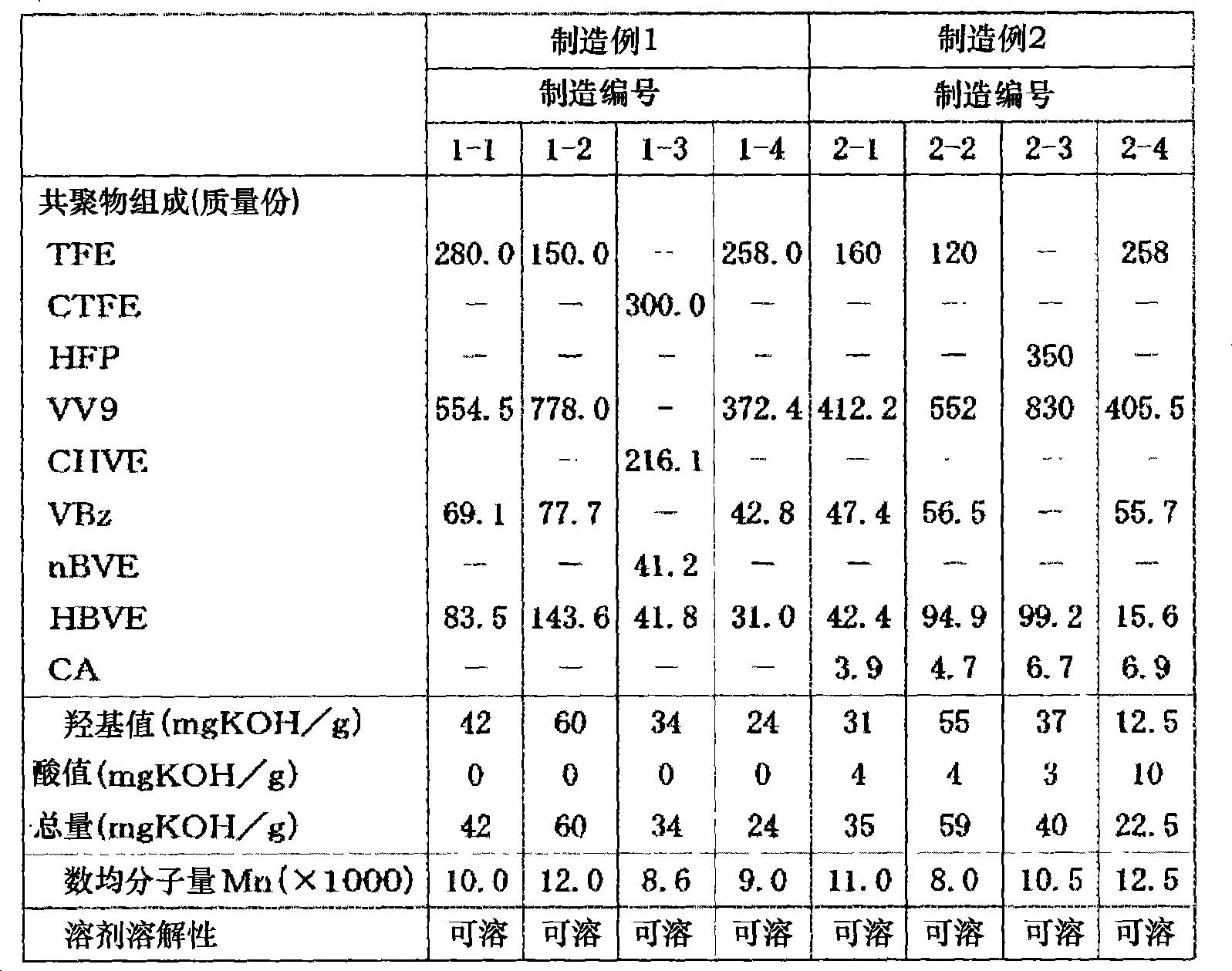

manufacture example 1

[0069] Production Example 1 (Production of Hydroxyl-Containing Fluorinated Copolymer)

[0070]Add 2500g butyl acetate, 554.5g Veova9 (hereinafter referred to as "VV9"), 69.1g vinyl benzoate (VBz), 83.5g 4-hydroxybutyl vinyl ether (HBVE) in a stainless steel autoclave with a volume of 6000ml, and cool After reaching 5°C, the operation of nitrogen replacement under reduced pressure was repeated three times. Finally, the pressure was reduced again and 280.0 g of tetrafluoroethylene (TFE) was added. Under stirring, the temperature was raised to 62.0° C., and 28.38 g of Peroxide PV (trade name, peroxide polymerization initiator produced by NOF Co., Ltd.) was added to initiate polymerization. When the internal pressure of the reactor decreased from 1.0 MpaG to 0.4 MpaG, the reaction was stopped. The polymerization yield was 98.0%. The resulting fluorine-containing copolymer was 19 F-NMR, 1 H-NMR and elemental analysis analysis prove that it is a fluorine-containing copolymer (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com