Original hollow cylinder sample top cover positioner

A hollow cylindrical sample and locator technology, which is applied in the preparation of test samples, sampling devices, etc., can solve problems such as soil properties and achieve the effect of ensuring authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

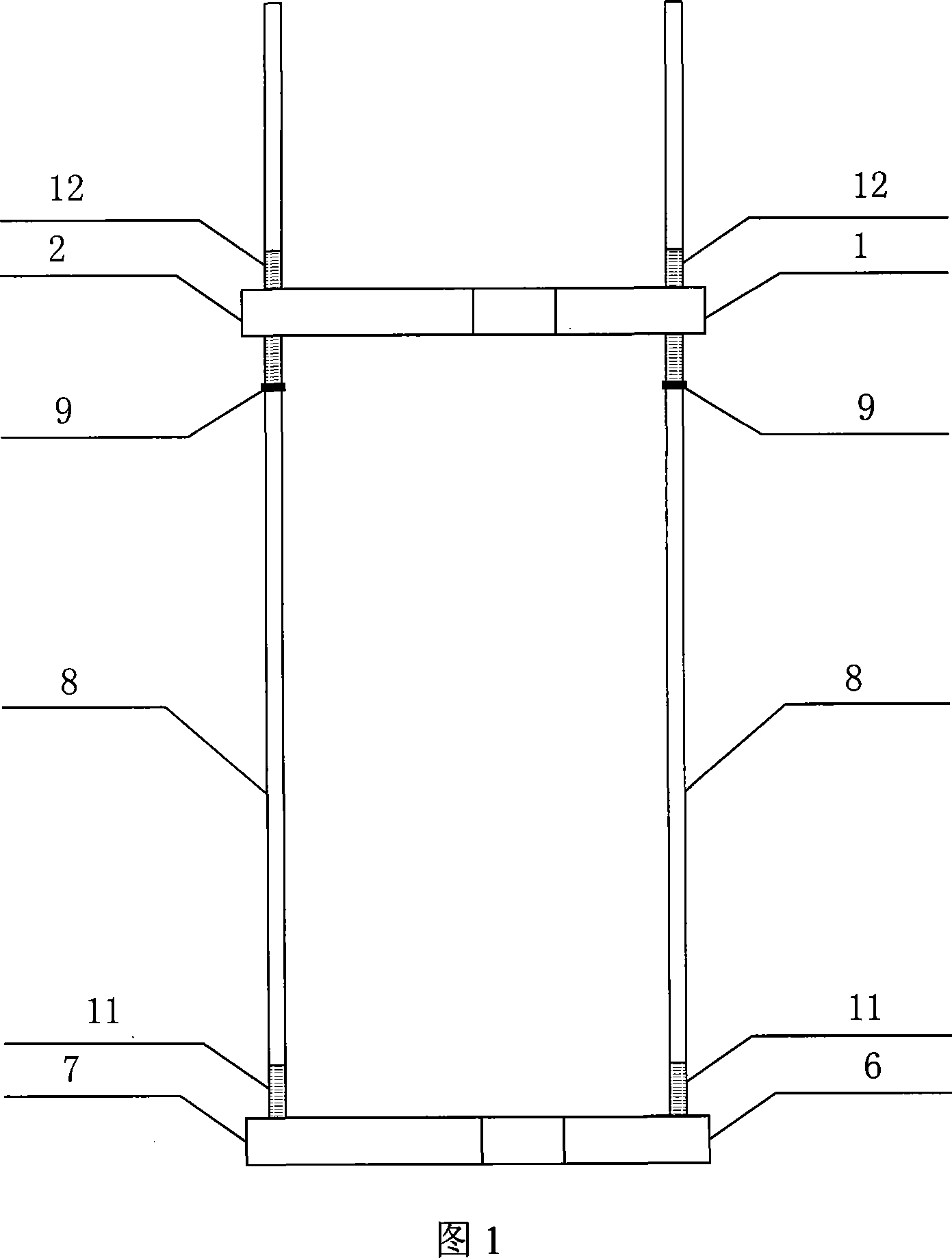

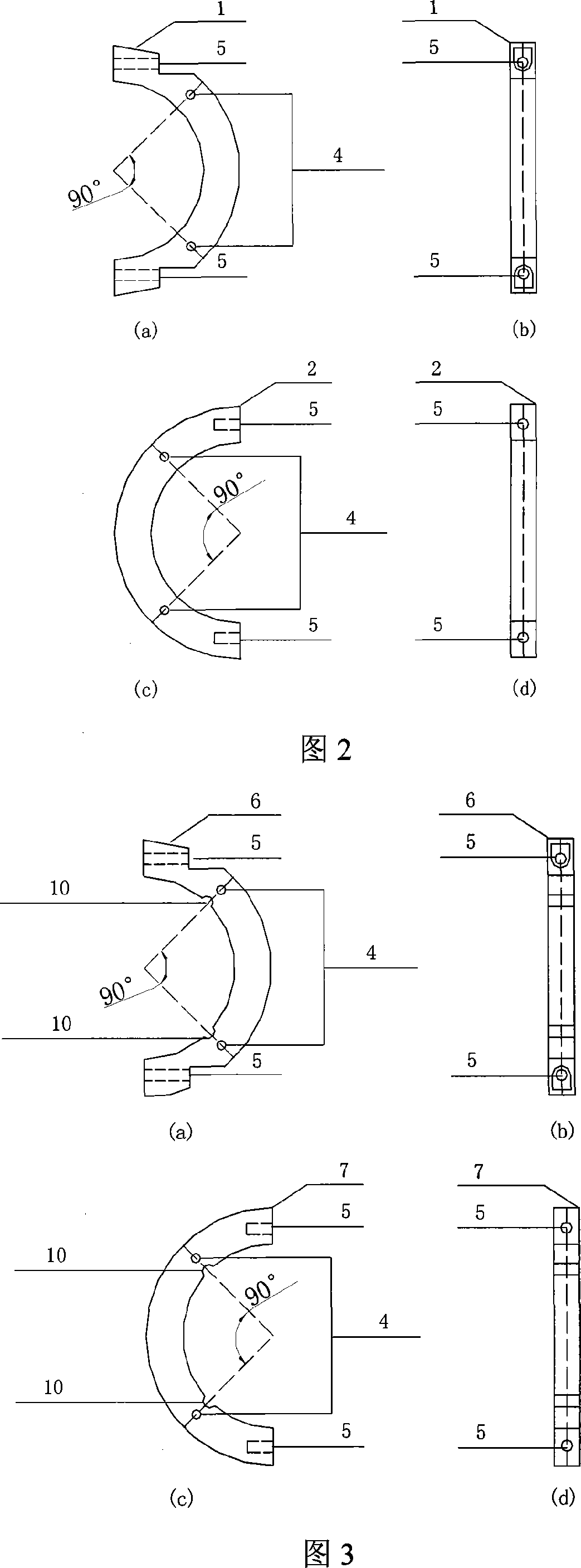

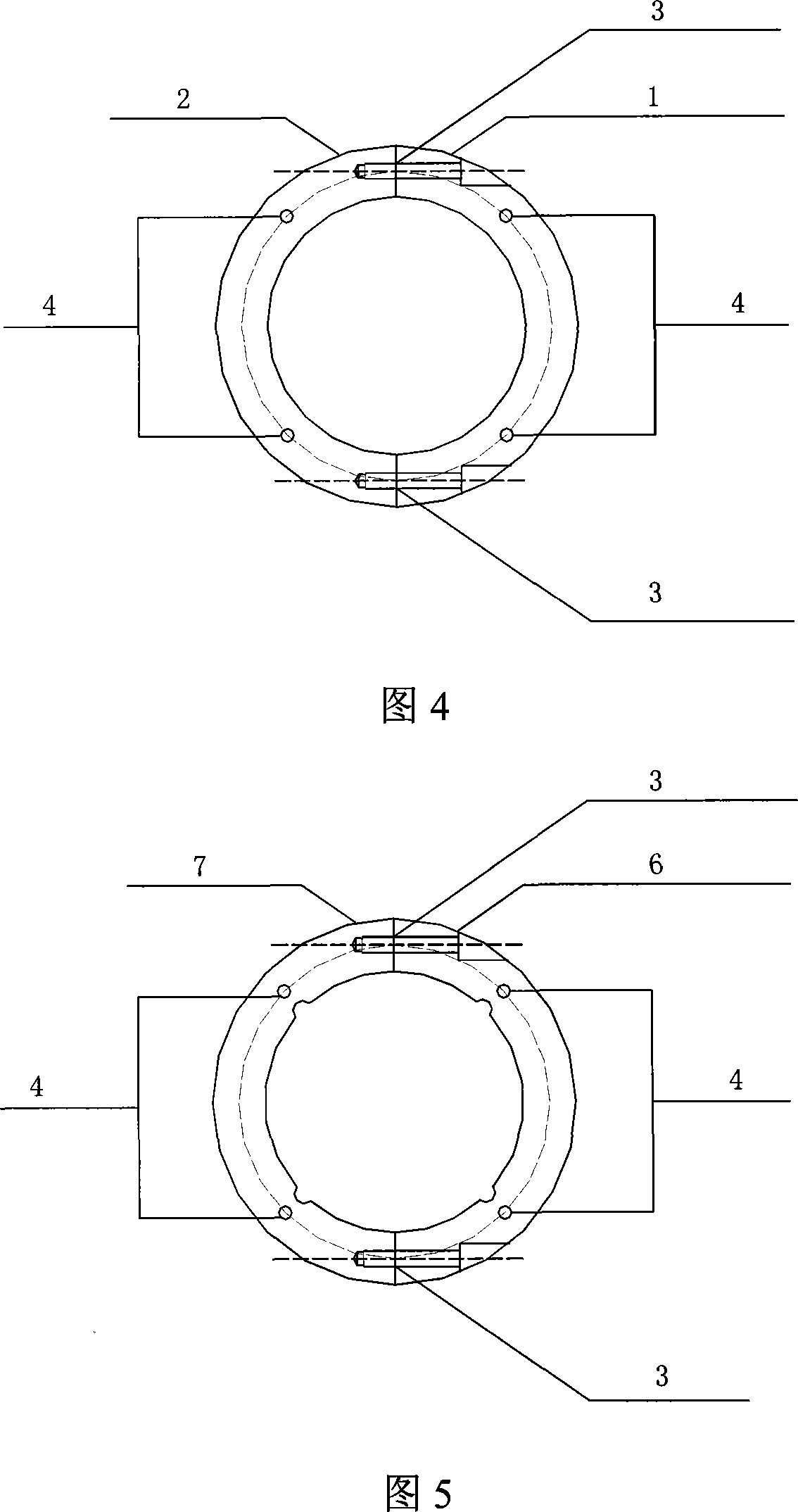

[0021] As shown in Figures 1, 2, 3, and 4, the positioner for the top cover of the original hollow cylindrical sample includes a right lobe stopper 1 on the upper part of the locator, a left lobe stopper 2 on the upper part of the locator, a stopper positioning screw 3, Positioner positioning screw hole 4, positioner closing screw hole 5, positioner lower right lobe positioner 6, positioner lower left lobe positioner 7, positioner adjustment screw 8, positioner adjustment screw positioning nut 9 , the sample base positioning groove 10, the positioner is provided with the positioner positioning screw hole 4, the positioner closing screw hole 5, the positioner adjustment screw 8 is provided with the positioner adjustment screw positioning nut 9, the positioner upper The right lobe retainer 1 and the upper left lobe retainer 2 of the locator are connected through the retainer positioning screw 3 to form the upper retainer of the locator, and the lower right lobe retainer 6 of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap