Turbine blade fatigue life evaluating method

A turbine blade, fatigue life technology, applied in the direction of engine life extension, blade support components, mechanical parts testing, etc., can solve the problems that have not been developed to quantitatively evaluate the fatigue life of turbine blade 1, gas turbine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

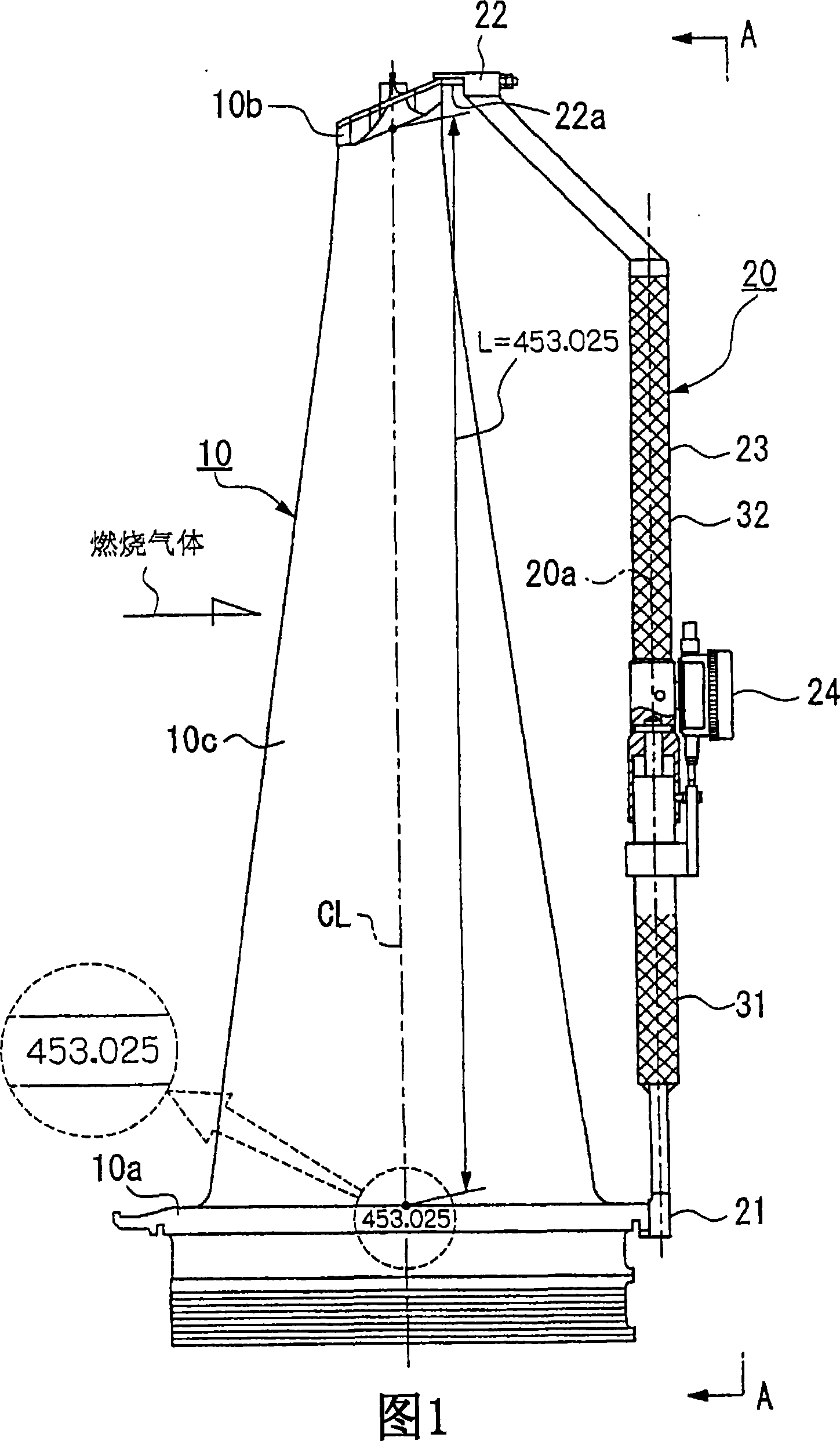

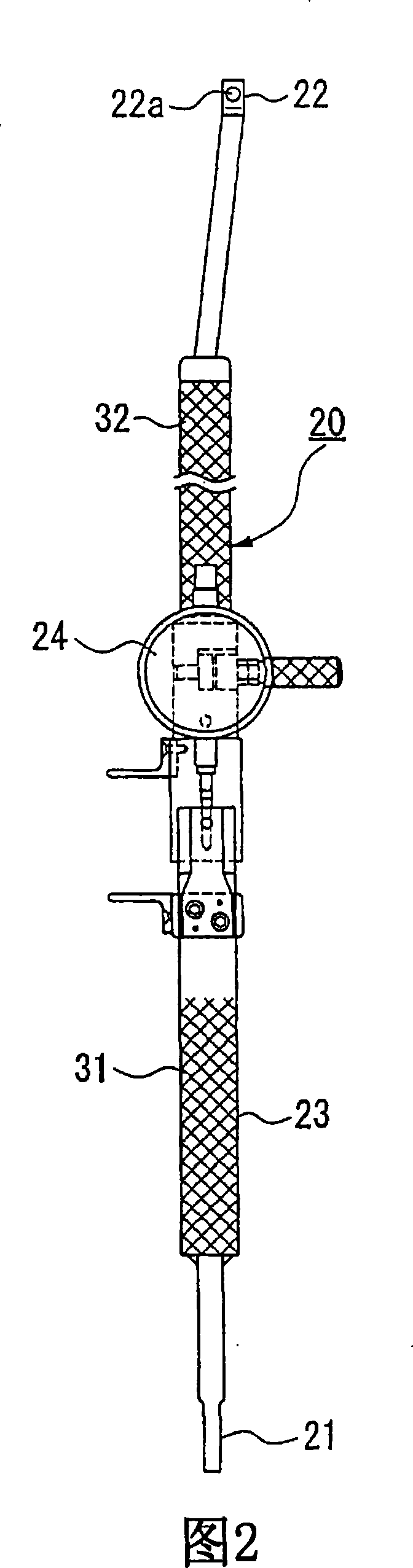

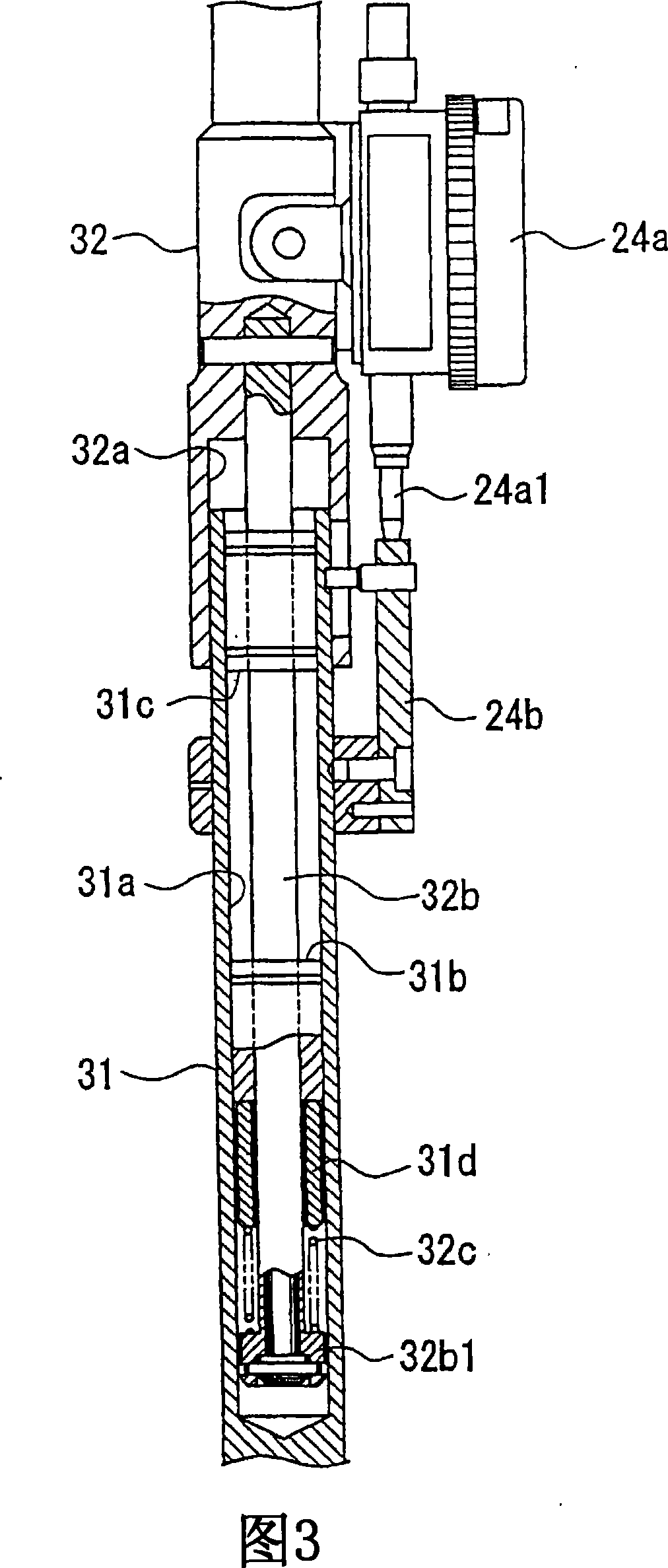

[0025] An embodiment of the turbine blade fatigue life evaluation method using the turbine blade creep elongation strain measuring device of the present invention and the turbine blade evaluated by the above method will be described with reference to the following drawings. In addition, the specific structural and functional descriptions set forth herein are representative only and do not limit the scope of the present invention.

[0026] The turbine blade of the present invention is not shown in the drawings, and is a member constituting a part of the turbine in a gas turbine including a compressor, a combustor, and a turbine. A rotor is axially supported for rotation within the turbine, and a plurality of turbine blades are secured around the rotor. In addition, the turbine causes the combustion gas generated in the combustion chamber to enter the combustion gas flow passage to expand. In addition, the rotor is rotated by blowing combustion gas against each turbine blade, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com