Automobile ceiling fabric elongation test device

A car roof and testing device technology, applied in the direction of testing the ductility of materials, using stable tension/pressure to test the strength of materials, etc., can solve problems such as excessive time, waste, and failure to solve problems in time to improve product quality , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

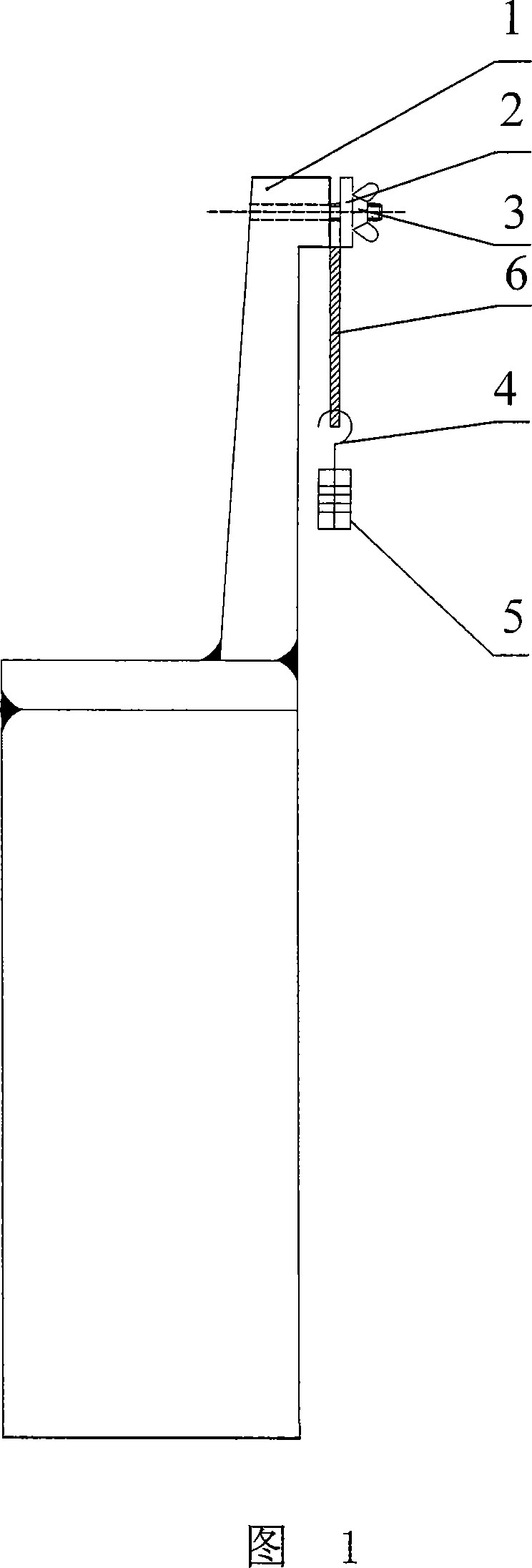

[0008] As shown in the figure: a pressing block 2 for clamping the material 6 is arranged on the upper part of the cantilever frame 1 , and a pressing mechanism for pushing the pressing block 2 to move is arranged between the pressing block 2 and the cantilever frame 1 . In the pressing mechanism, one end of the threaded part is connected with the threaded hole provided on the cantilever frame 1, and there is a through hole on the pressing block 2, and the pressing block 2 is sleeved on the outer end of the threaded part by using the through hole. Nut 3 is arranged on the threaded member outside briquetting block 2. There is a fabric 6 between the briquetting block 2 and the cantilever frame 1, a hook 4 is arranged under the fabric 6, and a weight 5 is arranged below the hook 4.

[0009] When working, first cut a piece of fabric sample, fix the upper end of the sample fabric 6 on the head of the cantilever bracket 1, tighten the round nut 3 to drive the pressing block 2 to cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com